Episode 22: Soil loads on the truck

When loading a truck from the rear, the loading area is often driven over with the forklift without a second thought. Very few people think about whether this is even permissible and whether the floor can withstand the load.

About the author:

In a series of specialist articles from the field, on topics relating to containers and trucks, you will receive first-hand professional knowledge.

How to secure cargo correctly and what are the basics of cargo securing?

They are developed and presented by Sigurd Ehringer, owner of SE-LogCon:

- VDI certified instructor for load securing

- Reference book author

- 8 years Project Manager

- 12 years with the Bundeswehr (company commander)

- 20 years of sales experience

- since 1996 consultant/trainer in logistics

- 44 years instructor/trainer in various fields

Episode 22: Floor loading at the truck

The technical regulation for the load capacity of a truck body can be found in EN-12642 code XL.

Load securing on road vehicles - "Superstructures on commercial vehicles - Minimum requirements; German version EN12642:2016" this is the title.

Unfortunately, this standard makes no reference to the load-bearing capacity of the floor, but only to the superstructure.

It is necessary to read another standard, namely DIN EN 283 "Swap bodies - testing".

This specifies in detail how the floors are to be tested. For the loader who is entrusted with loading a truck, this standard is usually not accessible. Therefore, he must adhere to the information provided by the manufacturers of trailers or specified by the Employer's Liability Insurance Association as a boundary condition.

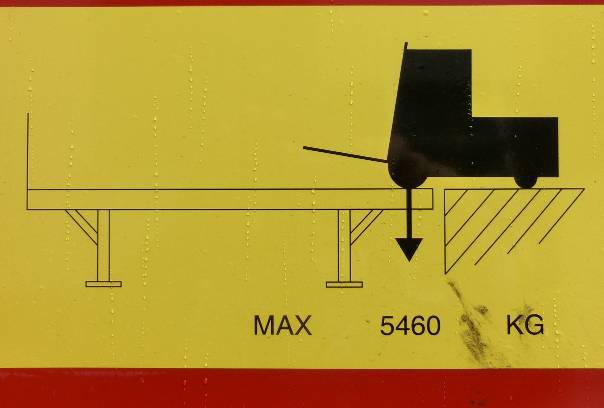

Manufacturers use, for example, the following markings, which are located mostly on the left or right side of the rear portal or on the inside of the door.

The maximum axle load for industrial trucks is specified at 5,460kg.

In this example, an axle load of 7,200daN is even specified.

The manufacturer Krone indicates a maximum axle load of 7,000kg in the picture

It must therefore be ensured that the load + forklift do not have a higher axle load. According to TIS-GDV, there should be no problems with forklifts with a maximum lifting capacity of 2.5 tons.

Driving on a loading area naturally also involves risks from the point of view of "occupational safety". Especially when the semitrailer is uncoupled from the tractor unit or the swap body is parked. In some cases, manufacturers make specific specifications, but in general, the loader must take this circumstance into account, even if no instructions are given.

When driving onto the empty trailer, the axle load can be too high, causing the truck to tip over and fall into the resulting gap. Here has

the manufacturer limits the axle load to 3,000kg.

Care must also be taken to block the trailer's axles with wedges to prevent it from rolling away.

The driver has to set the wedges and the loader has to control it.

Of course, there is also the critical situation when the first pallets are placed against the end wall with the forklift. Then it is in front of the support legs of the trailer.

If the axle load is more than 5,460kg, the trailer can tip forward.

For example, the manufacturer Kögel uses the marking to indicate that the empty trailer may only be driven on if it is supported at the front and rear.

The front support must still be positioned in front of the king pin. The attached parking supports are not sufficient.

Here is an example of how such a support may look.

The BGV D29 "Vehicles", with the new title "DGUV 70 Vehicles" says in § 37 "Loading and unloading" paragraph: (2) When loading and unloading vehicles, it must be ensured that they cannot roll away, tip over or overturn.

This is the clear specification of the employers' liability insurance association for accident prevention. It is therefore advisable to organize the processes in such a way that the regulations are complied with. This includes gathering the necessary information before loading to ensure safe loading and unloading.

Every company should have a clear work instruction/checklist for this situation to ensure a regulated process

As a Rothschenk test mount, I have already experienced quite a lot during load securing tests. Of course, loading and unloading is part of it. It's nice that the guys know what they're doing and don't make me tip over. 😉

On our own account:

Rothschenk. That's us.

Rothschenk is a manufacturer of load securing equipment for overseas containers. In the tranquil town of Aub in central Franconia, we develop, test and sell our own load securing equipment such as dunnage bags/padding, Lashing restraint systems, Edge Protectors, Anti-slip Mats, Lashing Straps and drum securement. You can get a small insight into our product world in our Online Shop: [R] SHOP24.

We develop for our customers, to whom also large corporations e.g. from the CHEMICALS-, BEVERAGES- and Automotive industry belong, individual load securing. Therefore we are used to come up with new products and solutions in our own research and test department.

We stand for quality "Made in Germany„. Not only in development, but also in production. Because we are the only manufacturer for load securing with our own production site in Germany. Real "Made in Germany" even.

>> Please use the comment function below for suggestions, additions and also for further questions.

We will, of course, respond promptly and professionally. Your Rothschenk Team

Comment (1)

I am in the process of having my truck built up. So of course I wanted to find out about the regulations. It's good to know that there is no reference to the load-bearing capacity of the floor in this standard.