Now 10% off all Ergolash lashing straps save now! Voucher code: ergo10 | Valid until 31.05.2025

Anyone who deals with the subject of load securing will also come across anti-slip mats at some point.

For some, they are a panacea, for others just a cost factor that is not needed.

How do anti-slip mats work and how necessary are they really for load securing?

The question that arises is where the truth lies. In order to answer this question, I would like to expand a little in order to create the necessary understanding of the problem.

Friction is a physical phenomenon that we all have to deal with. But we often don’t realize it because we know the effects and consider them normal. We become aware of the phenomenon when it has negative consequences or hurts.

A separate science, tribology, deals with this topic and Leonardo da Vinci already carried out experiments. Friction exists between bodies, surfaces or particles and prevents them from moving against each other. This creates a frictional force. It always counteracts the direction of movement.

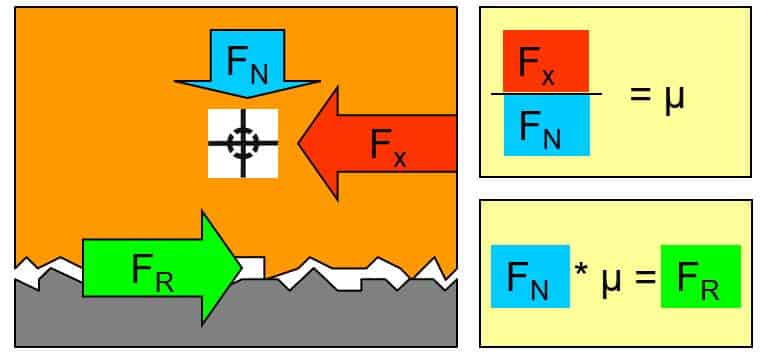

There are different types of friction, the best known being static friction, sliding friction and rolling friction. Sliding friction plays the main role in load securing. Work is necessary to overcome the frictional force. The frictional force results from the surface roughness at the contact surfaces of the bodies. The coefficient of friction μ describes the ratio of these roughnesses to each other.

Anyone who has ever worked on a piece of wood with sandpaper knows what I’m talking about. It is easier to work with fine sandpaper than with coarse sandpaper. However, the abrasion is also different. With fine sandpaper, the coefficient of friction μ is lower than with coarse paper.

Now comes the turn to load securing. If any load, regardless of its appearance, is placed on a loading surface, the situation of friction automatically arises. Two surfaces with different roughness are in contact with each other. If I want to move the load, I have to overcome the frictional force.

Accelerations, which inevitably occur during transportation, also lead to load movements if the acceleration is greater than the coefficient of friction.

If two surfaces lie on top of each other, the respective surface roughness results in an interlocking. This always counteracts the displacement force.

The normal force (FN) presses on the lower surface due to gravity. This is, for example, the load weight in daN, as a weight force. A force (Fx) must be applied to move it. The ratio of (FN) to (Fx) gives the coefficient of friction μ. It can be determined by testing. If the coefficient of friction μ is known, the frictional force can be calculated.

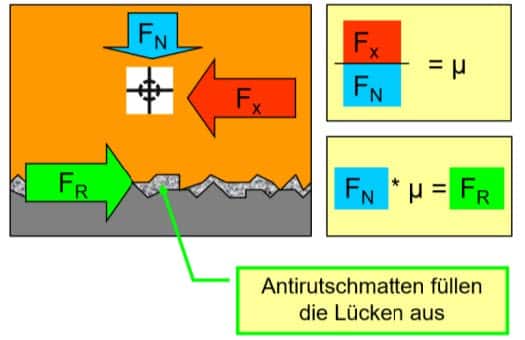

If anti-slip mats are used, the material fills the gaps between the serrations and a mini form fit is created.

This mini form fit increases the force required for displacement and, of course, the coefficient of friction μ.

This is the working principle of anti-slip mats.

The contact area between two bodies does not play a role in calculating the coefficient of friction μ, but it does in practical applications.

VDI-2700 Sheet 14 is available for the professional determination of a coefficient of friction. The technical procedure is described here so that the measured values are also representative and reliable.

The coefficient of friction can also be determined by means of tilt tests using on-board equipment. Although this is not so precise, it is often sufficient to see the size range in which the coefficient of friction lies.

VDI-2700 Sheet 15 describes the properties and requirements for anti-slip mats. This makes it clear that not everything made of “rubber” is also suitable as anti-slip mat.

Most granulate ARMs consist of styrene-budadiene-rubber (SBR) and natural rubber (NR), as well as polyurethane (PUR) as a binder.

The deformation behavior is tested with a 1,000 kg pallet cage over a period of 24 hours. No permanent deformations should be visible after the load has been removed. In practical applications, the size of the contact surface must be selected so that the deformation due to surface pressure does not exceed 30% of the initial thickness.

Tensile and shear strength also play a major role. The different surface roughness of the two surfaces between which the ARM is positioned leads to horizontal deformations during acceleration. For this to be uncritical, the tensile strength must be at least 0.6 N/mm².

The elongation at break of rubber ARM must be at least 60% under load. Frayed ARMs are often a sign of inferior quality or unsuitable material.

The surface pressure on ARMs with a large proportion of cavities can cause the material to become soapy and the coefficient of friction to drop considerably. If you hold the ARM against the light and a lot of brightness comes through, this is also a sign of poor quality.

The temperature resistance should be between -20°C and +100°C. If the operating temperatures deviate from this, further information must be obtained from the manufacturer.

ARMs can be declared as both disposable and reusable material. Particular attention must be paid to discard characteristics, especially with reusable ARMs. These characteristics can be

ARMs made of solid material are also available. During production, they are vulcanized or mixed together from 2 components.

The advantage is that fabric or metal can be incorporated, which means that they can be subjected to greater stress than normal ARMs.

When drawing up instructions or vehicle/equipment specifications, the quality specifications of VDI-2700 Sheet 15 should always be referred to as a binding agreement in the case of anti-slip material.

In the next episode, I will discuss the practical application of anti-slip mats. Unfortunately, mistakes are repeatedly made here that create a feeling of safety that is not fulfilled in the event of emergency braking or evasive maneuvers.

Yours, Sigurd Ehringer

Next article >>

Episode 39: Anti-slip mats Part 2: Avoiding application errors

Sigurd Ehringer

✔ VDI-zertifizierter Ausbilder für Ladungssicherung ✔ Fachbuch-Autor ✔ 8 Jahre Projektmanager ✔ 12 Jahre bei der Bundeswehr (Kompaniechef) ✔ 20 Jahre Vertriebserfahrung ✔ seit 1996 Berater/Ausbilder in der Logistik ✔ 44 Jahre Ausbilder/Trainer in verschiedenen Bereichen —> In einer Reihe von Fachbeiträgen aus der Praxis, zu Themen rund um den Container und LKW, erhalten Sie Profiwissen aus erster Hand. Wie sichert man Ladung korrekt und was sind die Grundlagen der Ladungssicherung? Erarbeitet und vorgestellt werden sie von Sigurd Ehringer, Inhaber von SE-LogCon.

Rothschenk assortment

Our customer center has only one goal: to turn your problems into solutions. Whether standard stowage cushions, bestsellers or load securing personally tailored to your needs -. we accompany you consistently from A as in field service to Z as in certification. That is our promise to you, as a leader in our industry.

We attach great importance to professional cargo securing. That is why we have our own production, which ensures reliable operation through modern manufacturing technologies and strict quality control. Thus, we offer our customers a comprehensive and high-quality range of services in the field of transport logistics.

DIN ISO 9001:2015, EMAS and Ecovadis are not foreign words to you? Then it's time to work with the best.

You don't take any risks with us - we have been awarded the Platinum Medal on the EcoVadis sustainability rating platform.

As a load securement company, we are proud to have several certifications that validate our sustainability efforts and our commitment to environmental protection and social responsibility. For you as a purchaser, this means that we demand and promote the implementation of high environmental and social standards both within the company and along the supply chain.

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information