Exploring the limits

Rothschenk

Fahrversuche

Driving tests are important for the customer when certifying load securing, as they offer various advantages. We give our all for our customers and explore what is feasible for them.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information- Road tests and training from load securing professionals

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationBrake test

Our products are subjected to numerous tests before they are allowed to secure our customers’ goods. At our premises, we carry out driving tests at the customer’s request, as well as braking tests on cordoned-off areas to prove the performance of our load securing systems.

Road tests

Our customers often have unusual products. Then it becomes necessary to find extraordinary solutions together with you. The best place to buy is directly from the manufacturer – from us. In-house test facilities enable driving tests and all conceivable load securing scenarios to be simulated.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationKanteltest

At sea, containers can be exposed to inclinations of 40% and more. Excellent load securing is essential to counter these forces. We simulate precisely these scenarios ourselves and on behalf of our customers on our carriage.

Dynamic driving tests

How we test for you

Brake test with truck

- Certification by external experts

- Dynamic test in the direction of travel

- Standardized test specifications for achieving the desired G-forces

- Suitability according to VDI 2700

Evasion test with truck

- Certification by external experts

- Dynamic test transverse to the direction of travel

- Standardized test specifications for achieving the desired G-forces

- Suitability according to VDI 2700

Overrun test with the train

- Certification by external experts

- Shock load during maneuvering

- Standardized test specifications for achieving the desired G-forces

Tilt test with carriage

- Certification by external experts

- Tilt angle up to 50° inclination

- Simulation of the angle of inclination for combined traffic (sea/truck/rail)

Engineering service. Made in Germany.

Test the best.

Everything has a beginning. Our customers’ products, as well as the load securing required for them. Objective: To transport them safely to their destination. As a manufacturer, we research our own solutions and subject them to many test runs and certifications. We are happy to make this expertise and the necessary technical equipment available to our customers on request. Gain first-hand experience.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

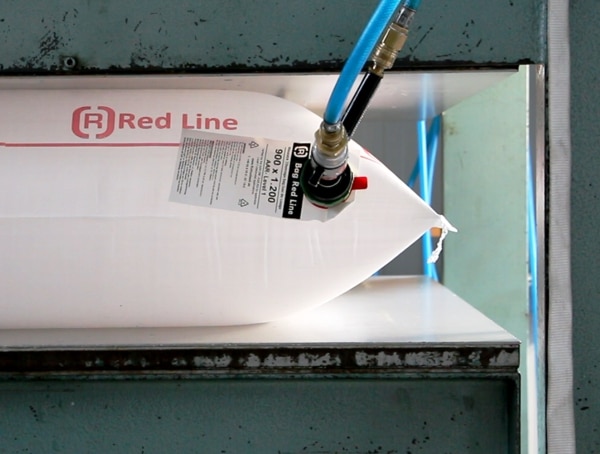

More InformationDunnage bag test

Our testing facilities really get down to business. Test values of 30 tonnes and more are sometimes achieved. Our dunnage bags have to prove that they are suitable for the tough everyday loading conditions in load securing.

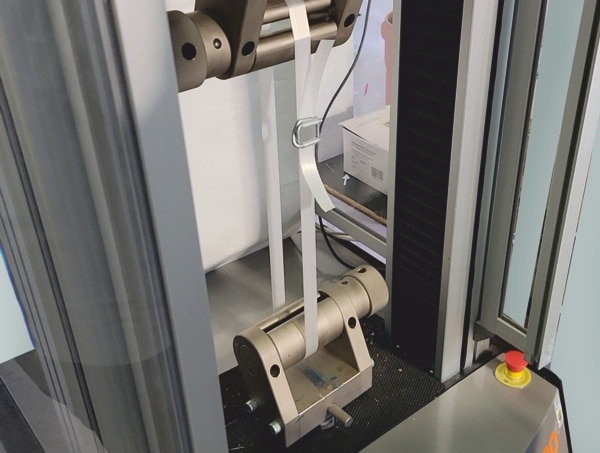

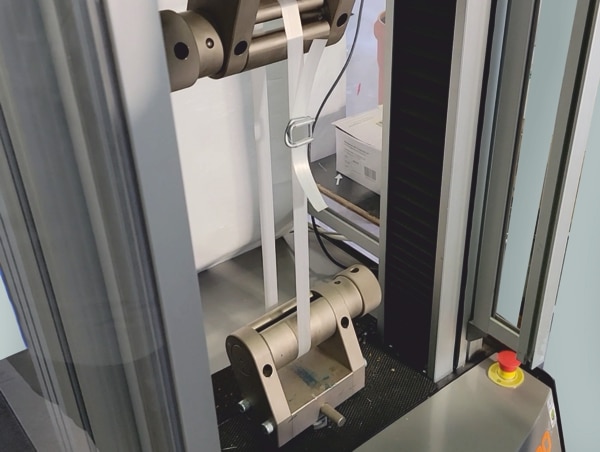

Lashing test

Lashing is not just lashing. This is because the weakest component determines the performance of the entire system. Our lashing test system is an indispensable testing tool for harmonising these factors in the best possible way. Use this tool for your own experiences.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

Tensile strength

As a self-manufacturing company, the highest material quality and professional production are among our greatest demands. Each of the components is put through its paces before further processing. For the webbing test, we have a specially designed tensile testing machine at our disposal.

Static tests - test systems

How we test for you

Tensile test system for lashing systems

- Maximum load capacity: 12 tons

- Eight recording points

- Digital measuring system with evaluation

Tensile test system for strapping

- Maximum load capacity: 10 tons

- Vertical pull

- Digital measuring system with evaluation

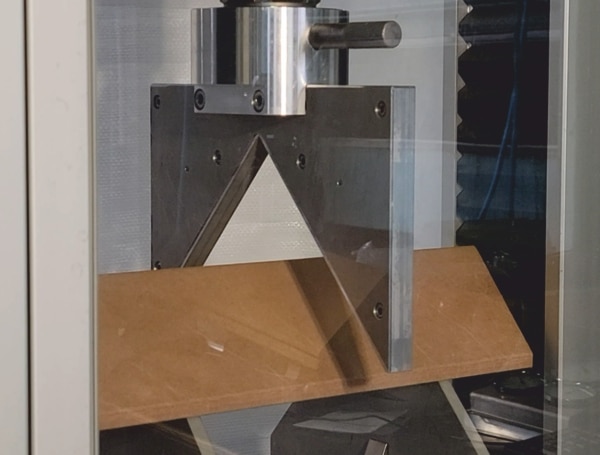

Pressure test system for edge protectors

- Maximum load capacity: 10 tons

- Vertical printing

- Digital measuring system with evaluation

- With holder for three-point bending test to ISO 178

Burst test system for dunnage bags

- Maximum load capacity: Level 5

- Test gap variable

- Digital measuring system with evaluation

Load unit tilt test

- External audit possible

- Certification of package formation

- Testing the stability of load units

- According to DIN and EUMOS

Working with the best.

Real partners.

Experience is important. That’s why we work with professional partners from the industry in many areas. For certifications, we have experts with decades of experience at our disposal who, as masters of their trade, uncover weak points and help to close these security gaps. We value this expertise. This circumstance is similar to our customer relationships. Grown over many years, based on partnership, sometimes even friendship. But always professional. What can we do for you?

Certification of load securing

Through road tests for the customer

Overall, road tests are important for the customer when certifying load securing, as they enable practical application, confidence and safety, error detection and optimisation, compliance with regulations and consideration of customer-specific requirements. They help to ensure that load securing is effective and reliable and meets the individual needs and requirements of the customer. Road tests therefore offer the following advantages.

Driving tests allow the customer to see and experience load securing in a real environment. This means that theoretical knowledge is put into practice and the customer can assess the effectiveness of the load securing methods and techniques themselves.

Driving tests allow the customer to gain confidence that the load securing methods and techniques actually work and keep the load safe and stable during transport. This creates a feeling of safety and reduces the risk of the load shifting, slipping or tipping over during transport.

Driving tests enable the customer to recognise potential weak points or errors in the load securing. By observing the behaviour of the load during transport, possible improvements or optimisations can be identified in order to further optimise load securing.

Road tests can help to ensure that load securing complies with the applicable regulations and standards. By carrying out road tests, potential infringements or non-compliances can be identified and rectified to ensure that the load securing meets the legal requirements.

Road tests allow the customer to address specific requirements or concerns regarding load securing. By carrying out road tests, individual solutions can be developed that meet the customer’s specific requirements and guarantee customised load securing.

More questions?

Send us a message

Industriestrasse 5 & 7-10

97239 Aub, Germany

Service hours:

Mon - Thu | 8:00 am - 5:00 pm Fri | 8:00 am - 1:00 pm Collection/delivery: Mon - Fri | 7:00 am - 3:00 pm

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information