Now 10% off all Ergolash lashing straps save now! Voucher code: ergo10 | Valid until 31.05.2025

If you have solutions, you have no problems. Unfortunately, this is only true in theory, but not in practice.

Inadequacies in load securing can be observed time and again with certain loads. The following explanations are intended to describe the situation in general and offer possible solutions.

I would like to explain my thoughts on why I came to the conclusion “problem load”. The considerations are based on the standard semi-trailer with the following data:

If we take the practical payload of 25,000 kg and divide it by the number of pallet spaces, we arrive at a weight of 735 kg per load unit.

As soon as a standard load unit is heavier than 735 kg, the 25,000 kg are reached, but the loading area is not full. As a rule, there is then a considerable distance to the rear portal under certain circumstances. The usual Code XL certificates state that with a maximum distance of 15 cm to the rear portal, the load does not need to be secured to the rear.

In my view, the following load units are examples of problem loads:

Example:

A standard IBC with the dimensions 100x120cm and a capacity of 1,000 liters plus its own weight of approx. 60kg can be roughly calculated at 1,060kg.

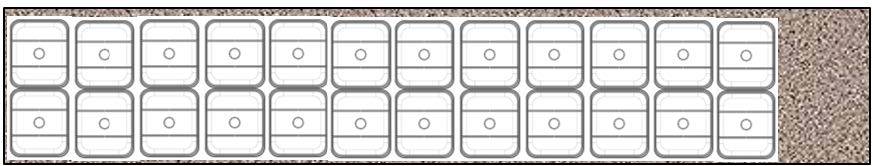

If we again take the practical payload of 25,000 kg and divide it by 1,060 kg, we arrive at 23.5 IBCs. Rounding up to 24 load units would result in a total weight of 25,440 kg. This could possibly still be uncritical. Presumably these IBCs would be loaded according to this pattern.

Mathematically, with 12 IBCs in a loading row, 1.60 cm will remain free up to the rear portal.

This means that the load must be secured to the rear. VDI-2700 specifies that an acceleration of 0.5g must be assumed when securing to the rear. The usual Code XL certificates specify the loading area with a coefficient of friction of μ=0.3, i.e. swept clean.

Roughly speaking, the load weight of 25,440 kg, which corresponds to 25,440 daN, can be multiplied by a factor of 0.2, resulting in a securing force of 5,088 daN. This is exactly where the next problem begins. The question of the securing method must now be asked.

Solution 1: most common, usually inadequate variant

Tie down each row of loads. However, experience shows that the frame of the IBC starts to bend if the pre-tensioning force exceeds 250daN. To secure the load anyway, 46 straps would be required. I have never seen more than 12.

Solution 2: feasible, but complex variant

Place each IBC on anti-slip mats and then lash down with 250daN per strap. The load would be adequately secured with 12 straps, i.e. one per row.

Solution 3: common, but completely inadequate

Secure the load with two to three clamping boards. When new, manufacturers state the blocking force BC as 400daN. You don’t have to be an arithmetic artist to realize that this is not enough if 5,088daN is required.

Solution 4: somewhat complex, but perfectly adequate

Position two pallets on edge at the last row of loading and create a head lashing with two belts. The belts transfer the force in direct tension to the attachment points, each of which must hold 2,000daN. Four attachment points are loaded, resulting in a sufficient securing force of 8,000daN. Of course, two head lashings with one strap each would also be conceivable, if one of them is positioned after the sixth row of loads and one at the end.

Solution 5: Simple and safe

The truck carries three locking beams with a BC of approx. 4,500daN per beam. Two of these are required. A securing force of 9,000daN can be generated quickly, easily and safely.

The considerations described are intended to provide a framework within which every shipper can introduce their load and find a solution. In practice, only solutions 4 and 5 really make sense. Solution 4 can be implemented at any time with “on-board resources”. Solution 5 requires insight and planning. Every standard semi-trailer should actually be equipped with a barrier beam system. Unfortunately, manufacturers usually do not offer it as a package, but as an optional extra. Vehicle owners should plan ahead when it comes to load securing. The shipper, who has to plan the securing of his load, should ask the carrier to provide such a system on his own initiative.

The IBC is in itself a loading unit that is stable and can be well secured. Octabins or big bags are more difficult. I will describe what to do with these loads, apart from what is described above, in one of the next articles.

It would be nice if the companies that have such load units transported would look into the matter and find a solution. My contributions are not ideal solutions, but are intended to encourage the development of company-specific solutions.

Tackle it, there is still a lot to do.

<< Previous post

Episode 58: Edge protectors & edge gliders: the correct use

To the next post >>

Rothschenk assortment

Our customer center has only one goal: to turn your problems into solutions. Whether standard stowage cushions, bestsellers or load securing personally tailored to your needs -. we accompany you consistently from A as in field service to Z as in certification. That is our promise to you, as a leader in our industry.

We attach great importance to professional cargo securing. That is why we have our own production, which ensures reliable operation through modern manufacturing technologies and strict quality control. Thus, we offer our customers a comprehensive and high-quality range of services in the field of transport logistics.

DIN ISO 9001:2015, EMAS and Ecovadis are not foreign words to you? Then it's time to work with the best.

You don't take any risks with us - we have been awarded the Platinum Medal on the EcoVadis sustainability rating platform.

As a load securement company, we are proud to have several certifications that validate our sustainability efforts and our commitment to environmental protection and social responsibility. For you as a purchaser, this means that we demand and promote the implementation of high environmental and social standards both within the company and along the supply chain.

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information