Now 10% off all Ergolash lashing straps save now! Voucher code: ergo10 | Valid until 31.05.2025

The use of dunnage bags in containers is a common method and has become an integral part of the repertoire of securing methods.

The CTU Code devotes an entire chapter to dunnage bags in Appendix 7 Annex 4 and refers exclusively to sea containers, ignoring trucks altogether. It therefore seems appropriate to shed light on the subject and explain the advantages and risks. Reference should also be made to the section 48 “Loading of dunnage bags”.

In general, dunnage bags are used to close existing gaps between loading units and to transfer the resulting acceleration forces of the load to the fixed superstructures of the means of transport without interruption.

For the application, it is important to know that a dunnage bag can only absorb and transfer forces over its entire surface.

First of all, a few basic notes on positive locking, as this is often discussed in different ways in the loading community. The term tight fit comes from connection technology and means the fixed, not freely movable connection of two components. In load securing, the term tight fit is used when the load is stowed in such a way that there are no gaps to the load-bearing superstructures.

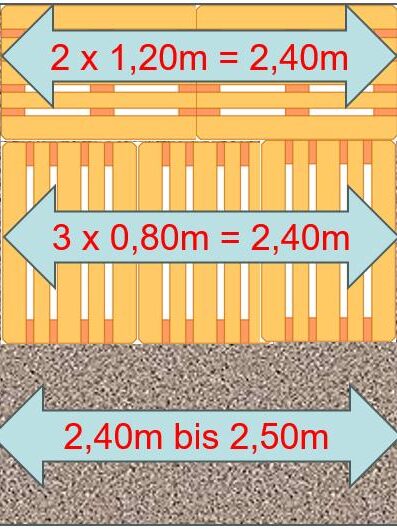

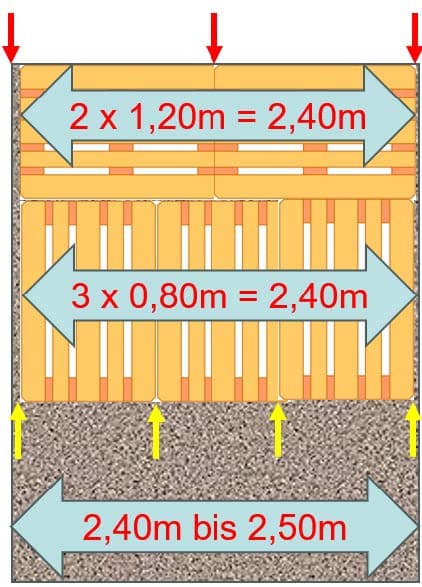

The practitioner knows that gaps cannot be avoided, but how big can they be? That is why the regulations allow a certain uncritical gap sum, depending on the means of transport. For trucks, this can be illustrated with the following graphics.

The dimensions of the means of transport in Europe are designed to the dimensions of the Euro pallet. We can speak of a tight fit if two Euro pallets are stowed crosswise or three lengthwise on the truck.

The sum of the permissible gaps is the difference between the inside loading width of the body minus 2.40 m.

Example: 2.45m – 2.40m = 0.05m = 5cm

If you take a closer look, there are 3 or 5 gaps depending on the type of congestion.

This means that the total gap calculated above is divided again into 3 gaps = 1.6 cm or

into 5 gaps = 1 cm.

That’s all very sporty and theoretical, but basically correct.

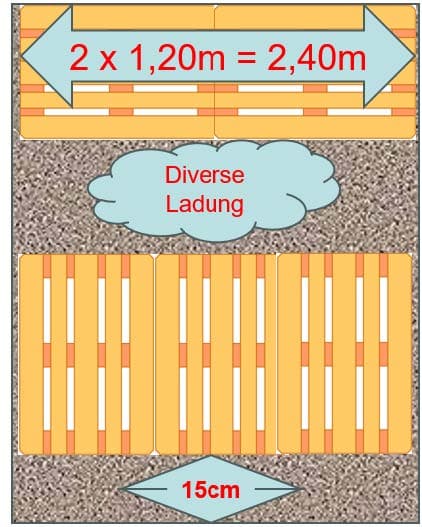

Most semi-trailer manufacturers allow a maximum gap of 15 cm to the rear.

In specific cases, the body certificate should be consulted in order to obtain precise information.

However, the main problem is the load units, because in many cases they are not packed in such a way that they form a block with the basic dimensions of 1.2m x 0.8m. They are often over- or under-built, have gaps between the individual packages or do not fit snugly into the means of transport for other reasons.

The chemical pallets in the CP series deviate from the Euro dimensions, with the exception of the CP-2. In addition to the Euro pallet, there are many other variants, not to mention the special pallets.

It is precisely in these situations that dunnage bags could provide a solution. Of course, there are a few boundary conditions to consider.

A few examples

Positive!

Using dunnage bags in a refrigerated box body to fill gaps is a good idea. However, it is important to ensure that the load compartment is not completely full.

What then? How can the rear fuse be released?

Possible volume fluctuations due to temperature changes must also be taken into account.

Negative!

This example is by no means acceptable.

According to the manufacturer’s specifications, clamping rods have a maximum blocking force of 150daN across the entire width. This will most likely not be enough.

Positioning a dunnage bag against a safety bar is not permitted because a surface must always be available for force transmission.

Negative!

In this case, the means of transportation is a container, but the dunnage insert is completely inappropriate.

Upholstery against upholstery is not permissible because no balance of forces is achieved. The cushions give way during movement. The large pad on the left will probably be lying loosely on top after a short ride.

Positive!

This dunnage bag transfers the forces over the entire surface and reliably fills the gap.

Positive!

Although this picture shows a container, this type of dunnage bag with dunnage bags as gap fillers could also be used on a semi-trailer with a tarpaulin body. The dunnage bags are positioned between the load.

The inclined reader can see that, taking into account the boundary conditions, the dunnage bag in the truck sector is definitely justified.

Stay tuned, the next episodes with interesting topics are coming.

Yours, Sigurd Ehringer

To the next post >>

Sigurd Ehringer

✔ VDI-zertifizierter Ausbilder für Ladungssicherung ✔ Fachbuch-Autor ✔ 8 Jahre Projektmanager ✔ 12 Jahre bei der Bundeswehr (Kompaniechef) ✔ 20 Jahre Vertriebserfahrung ✔ seit 1996 Berater/Ausbilder in der Logistik ✔ 44 Jahre Ausbilder/Trainer in verschiedenen Bereichen —> In einer Reihe von Fachbeiträgen aus der Praxis, zu Themen rund um den Container und LKW, erhalten Sie Profiwissen aus erster Hand. Wie sichert man Ladung korrekt und was sind die Grundlagen der Ladungssicherung? Erarbeitet und vorgestellt werden sie von Sigurd Ehringer, Inhaber von SE-LogCon.

Rothschenk assortment

Our customer center has only one goal: to turn your problems into solutions. Whether standard stowage cushions, bestsellers or load securing personally tailored to your needs -. we accompany you consistently from A as in field service to Z as in certification. That is our promise to you, as a leader in our industry.

We attach great importance to professional cargo securing. That is why we have our own production, which ensures reliable operation through modern manufacturing technologies and strict quality control. Thus, we offer our customers a comprehensive and high-quality range of services in the field of transport logistics.

DIN ISO 9001:2015, EMAS and Ecovadis are not foreign words to you? Then it's time to work with the best.

You don't take any risks with us - we have been awarded the Platinum Medal on the EcoVadis sustainability rating platform.

As a load securement company, we are proud to have several certifications that validate our sustainability efforts and our commitment to environmental protection and social responsibility. For you as a purchaser, this means that we demand and promote the implementation of high environmental and social standards both within the company and along the supply chain.

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information