Now 10% off all Ergolash lashing straps save now! Voucher code: ergo10 | Valid until 31.05.2025

The edge protector bracket (KSW) is an aid in load securing. Unfortunately, the commonly known term gives a false impression of its essential function.

I would like to say a few words about this in this blog.

The edge protection bracket should actually be called an edge slider, as its main task is to distribute the pre-tensioning force as evenly as possible over the entire load. This means that the friction between the tensioning strap and the KSW should be as low as possible. It is therefore clear that it is mainly used for tie-down lashing, because the pre-tensioning force in conjunction with the frictional force is the essential element here.

The raw material for KSW is very diverse. Plastics are predominantly used, but metals, recycled materials and cardboard are also used. Each material has advantages and disadvantages that always depend on the specific application.

The variety of edge protection is large and there are always new solutions and variants.

Whether they actually meet the requirements in the actual application is sometimes questionable.

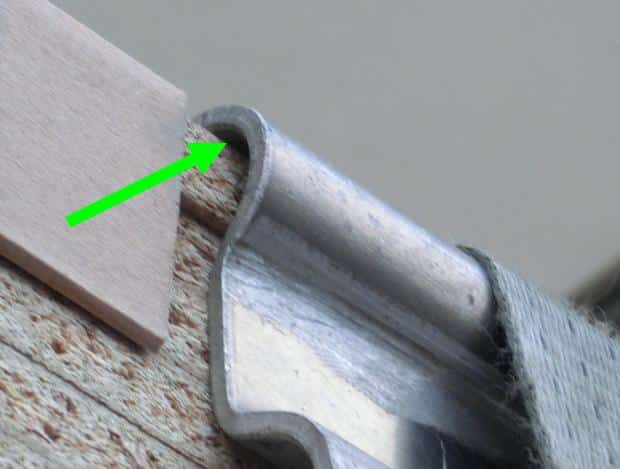

This picture shows that the bracket is already damaged and can therefore no longer fulfill its core function.

This can be caused by brittle material, incorrect use or age-related material fatigue.

Drivers and loaders should discard and replace this bracket.

When applying the pre-tensioning force, the load can be damaged with a stable bracket. If the bracket is unstable, it will bend/deform and be permanently damaged. What to do?

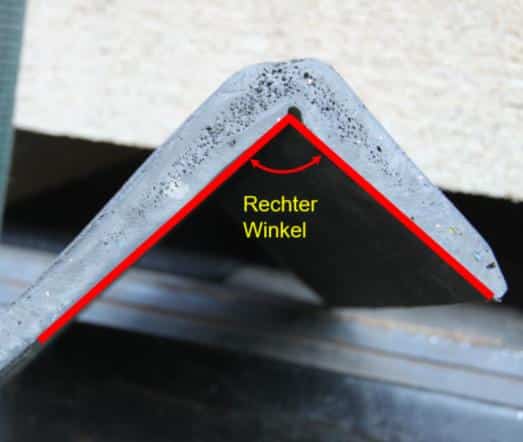

Some KSWs are designed in such a way that they form a groove to protect particularly sensitive edges of the load.

This is the case with board products. E.g. chipboard, plasterboard, tongue and groove boards, etc.

This will usually work well with metal angles.

This angle bracket with groove has been specially manufactured from stable, rigid plastic material for the paper sector.

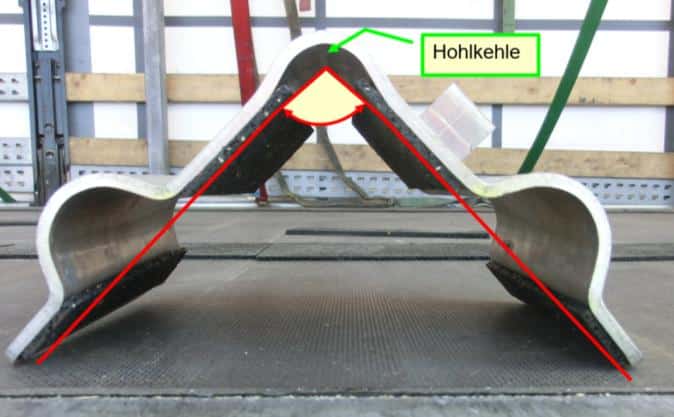

It can also be used for loads that also have right-angled edges. However, as soon as the lashing angle becomes significantly smaller than 90°, unfavorable loads are applied to the angle.

If it is used with non-rectangular loads, it will break during tensioning.

In this picture, you can see that the damage has already occurred with another load and the damage is particularly evident here, although this load would be suitable.

In this situation, a high pre-tensioning force not only reduces the distribution of the tensioning force, but also damages the fabric.

Edge protection brackets made of sturdy, glued cardboard provide good service in many cases and improve the distribution of the pre-tensioning force.

If the edges of the material also need to be protected, then this angle variant is more likely to be out of its depth.

These sturdy edge protectors have become particularly popular in the construction industry because they are available in different lengths.

Comparable brackets are also made of steel or aluminum.

Another aspect is the use of edge protection brackets to keep the load compact and secure it more stably.

This means that long, stable edge protection brackets can be used to group loading units together. At the same time, the securing effort is reduced.

Other load units with similar proportions can also be secured in this compact way. E.g. beverages, IBCs, drums, etc.

A comparable effect can also be achieved with brackets made of aluminum or steel. However, handling and the risk of accidents must also be taken into account.

Sturdy sheet metal edge protectors can also be used to create a head flashing without any problems. Two brackets are required. Three straps can be used on this bracket.

These brackets are now available in a wide variety of versions. The picture shows a bracket designed for two tension belts.

The securing force results from the sum of the active attachment points on the truck. Two belts transfer the force to four lashing points.

This results in an approximate securing force of approx. 8,000daN without taking into account the lashing angle and the frictional force, which may be necessary.

For brick pallets that are unloaded with the clamping fork, care must be taken to ensure that a spacer is used at the end or beginning of the load.

It ensures that the belt circumference and thus the securing force are maintained when braking.

The above information shows that edge protectors/edge protectors are a product with potential that can be exploited to the full. The knowledgeable reader will be able to filter out the essential boundary conditions from the presentation and apply them to other loads.

The aim must always be to secure the load quickly and efficiently against any acceleration and movement. The assistants installed in the new trucks, which can no longer be switched off, increase the risk of the assistant intervening with an emergency stop where the driver would perhaps only have taken off the accelerator.

It would be nice if all those involved would look into the matter. My contributions are not silver bullet solutions, but information for developing company-specific solutions.

Tackle it, there is still a lot to do.

Yours, Sigurd Ehringer

To the previous post >>

Episode 57: Dunnage bags in trucks: the correct way to use them

To the next post >>

Rothschenk assortment

Our customer center has only one goal: to turn your problems into solutions. Whether standard stowage cushions, bestsellers or load securing personally tailored to your needs -. we accompany you consistently from A as in field service to Z as in certification. That is our promise to you, as a leader in our industry.

We attach great importance to professional cargo securing. That is why we have our own production, which ensures reliable operation through modern manufacturing technologies and strict quality control. Thus, we offer our customers a comprehensive and high-quality range of services in the field of transport logistics.

DIN ISO 9001:2015, EMAS and Ecovadis are not foreign words to you? Then it's time to work with the best.

You don't take any risks with us - we have been awarded the Platinum Medal on the EcoVadis sustainability rating platform.

As a load securement company, we are proud to have several certifications that validate our sustainability efforts and our commitment to environmental protection and social responsibility. For you as a purchaser, this means that we demand and promote the implementation of high environmental and social standards both within the company and along the supply chain.

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information