Now 10% off all Ergolash lashing straps save now! Voucher code: ergo10 | Valid until 31.05.2025

In episode 59, I addressed the topic of “problem loads” in general and would now like to condense it using the example of various loading units. Today I would like to focus on the octabin.

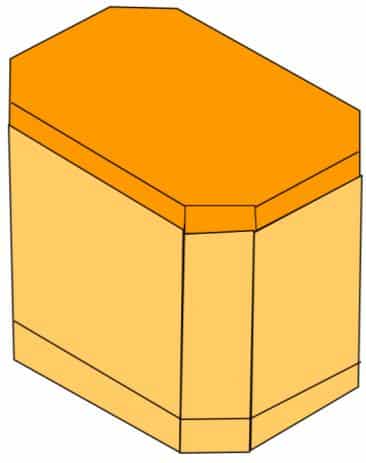

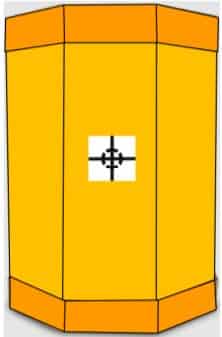

The octabin is an octagonal transport container, usually made of corrugated cardboard.

The dimensions are often adapted to the rectangular load carrier used. Euro pallets and industrial pallets are common.

The height can be between 80 and 200 cm and it can take loads weighing up to 1.2 tons.

The octabin often consists of three parts. The base or bottom part, the lid or top part and the casing part.

Depending on the material to be filled, inlays made of plastic film can also be used.

It can also be designed so that the base and lid can be telescoped in order to adjust the height variably.

Octabins are often used to transport bulk materials such as plastic granulate from recycling. The pourability, or the angle of repose, has an influence on the material quality. The more free-flowing or the flatter the angle of repose, the more stable the octabin should be.

Depending on the filling level, the center of gravity is approximately halfway up the filling.

In the event of emergency braking or evasive action, the contents in the octabin will move. The entire structure will give way and the center of gravity will shift.

The more free-flowing the material, the more unstable the octabin and the more free space there is on the means of transportation, the greater the deformation will be.

This creates the so-called domino effect. The greater the distance to the end wall, or the sum of the gaps, the greater the deformation.

It can become so large that the last rows of loads can no longer be unloaded with the forklift.

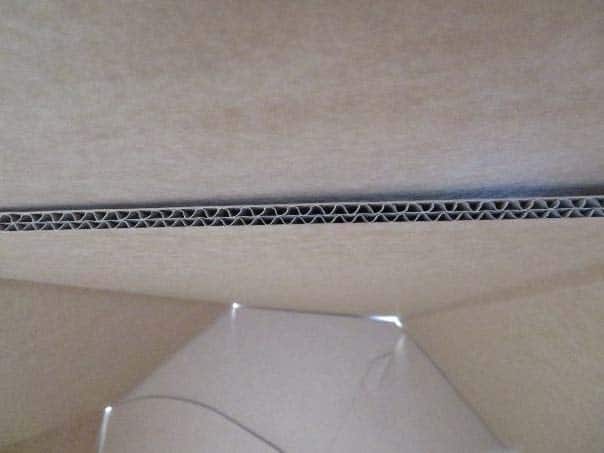

The floor construction of the octabin shows that it cannot absorb the occurring forces and also deforms.

Securing by lashing down cannot prevent this. It is more likely to result in the structure of the octabin being damaged by the pre-tensioning force.

What are the causes and what can be done about them?

VDI 2700 Sheet 18, which has been available as a green print since 2024, should be mentioned in this context. Although it deals with big bags and bagged goods, analogous solutions can be worked out for the securing methods. I will come back to this later.

A frequent cause of transportation problems is the fact that the dimensions of the octabins are designed for transport by sea container and then they are shipped on a truck. Of course, this also works the other way round. This means that free spaces are created on/in the means of transportation, which are filled by the deformation of the octabins when acceleration occurs. These deformations are the core of the problem and must be prevented.

The risk of transport damage is already significantly reduced if the dimensions of the octabins are adapted to the means of transport. For trucks, this is a loading width of 2.40 m and 2.34 m for containers. Container pallets often have a side dimension of 1.14m, which automatically results in a difference of [ 240cm – (2x 114cm) =] 12cm when loading onto trucks. This means that the body strength according to Code-XL to the side can no longer be used without further measures.

One side edge of the octabin should be 120 cm or 80 cm long so that the loading width in the truck is filled.

This can significantly reduce the amount of free space.

The corrugated cardboard from which the octabins are made is also not a run-of-the-mill product, but a high-tech material.

Depending on what is to be transported, it must be at least double-walled.

The “tie-down lashing” securing method is complex, but provides little securing force because the octabin yields to the pre-tensioning force and deforms, causing the force to be lost. The most effective method is the tight fit, in which the load is stowed without any significant gaps. Spaces should be avoided as far as possible, secured or filled.

Choosing a suitable vehicle is just as important.

Vehicles with box bodies are ideal. However, they should be equipped with at least two combination anchor rails so that, depending on the stowage situation, intermediate securing devices can be inserted after every second/third/fourth row of loads. If a vehicle with a tarpaulin body is available, securing is somewhat more complex, but feasible.

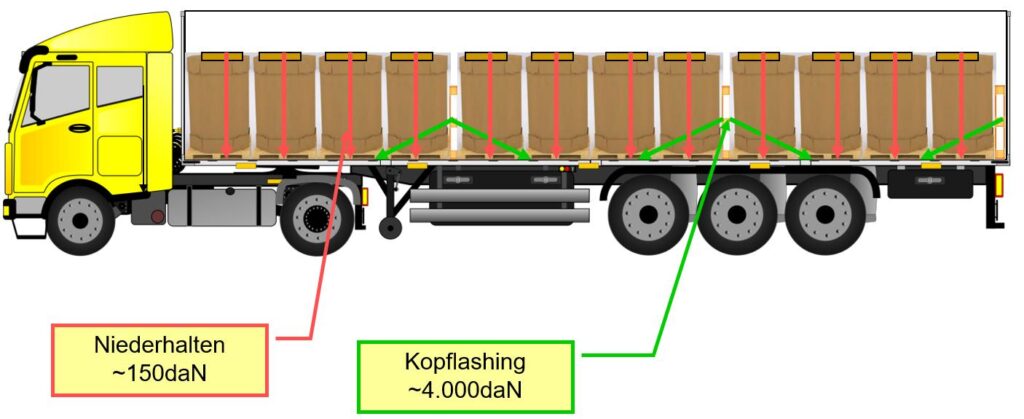

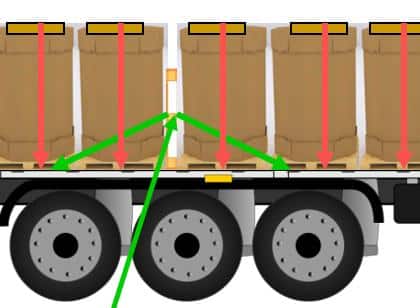

Here, too, it would be ideal if a stable locking beam system were available. Unfortunately, this is not standard equipment, but should be requested by the client together with the transport vehicle. Of course, securing can also be achieved with “on-board equipment”, i.e. pallets and straps. This diagram illustrates the principle.

After every fourth row of loads or as the situation requires, place two pallets upright between the rows of loads and thread the straps for the head lashing. The required lateral securing force is achieved by the strength of the Code XL body, provided the loading width is 2.40m. Pay attention to this.

The mutual belt tension creates a fixed partition wall on the loading area with the pallets. In addition, each row of loads can be secured with a head lashing. A pre-tensioning force of approx. 50-100daN (hand-tight) is sufficient.

This diagram is intended to show the principle of how the straps for the head flashing should be threaded so that additional pressure is exerted against the octabins when tensioning. The actual securing force only comes into play when a movement occurs due to acceleration.

The lashing eyes on the standard truck must have a lashing capacity of 2,000daN. This means that a head lashing with a belt that has an LC of 2,000daN can generate a securing force of approx. 4,000daN.

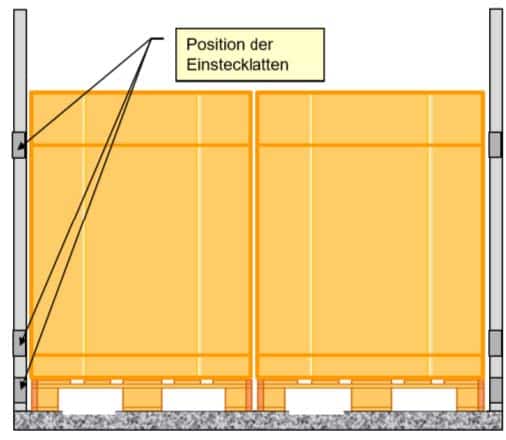

Care must be taken to ensure that the number of slats is balanced on both sides before loading begins. Minimum requirement: In the lower area, the insertion slat(s) should be positioned in the area of the pallet and the octabin floor.

An insertion slat must also be fitted in the upper quarter of the octabin so that the room for movement is restricted as much as possible.

The aim of all measures must be to keep the free space for load movements as small as possible. For octabins that are considerably higher than 1.20 m (Euro pallets on edge), consideration should be given to replacing the upright Euro pallets with a comparable construction in order to transfer the securing force of 4,000 daN over a larger area.

In the next part on problem loading, I will present further solution approaches.

It would be nice if the companies that have such load units transported would look into the matter. My contributions are not ideal solutions, but are intended to encourage the development of company-specific solutions.

Tackle it, there is still a lot to do.

<< Previous Post

Episode 59: Problem loads – What is the solution?

Sigurd Ehringer

✔ VDI-zertifizierter Ausbilder für Ladungssicherung ✔ Fachbuch-Autor ✔ 8 Jahre Projektmanager ✔ 12 Jahre bei der Bundeswehr (Kompaniechef) ✔ 20 Jahre Vertriebserfahrung ✔ seit 1996 Berater/Ausbilder in der Logistik ✔ 44 Jahre Ausbilder/Trainer in verschiedenen Bereichen —> In einer Reihe von Fachbeiträgen aus der Praxis, zu Themen rund um den Container und LKW, erhalten Sie Profiwissen aus erster Hand. Wie sichert man Ladung korrekt und was sind die Grundlagen der Ladungssicherung? Erarbeitet und vorgestellt werden sie von Sigurd Ehringer, Inhaber von SE-LogCon.

Rothschenk assortment

Our customer center has only one goal: to turn your problems into solutions. Whether standard stowage cushions, bestsellers or load securing personally tailored to your needs -. we accompany you consistently from A as in field service to Z as in certification. That is our promise to you, as a leader in our industry.

We attach great importance to professional cargo securing. That is why we have our own production, which ensures reliable operation through modern manufacturing technologies and strict quality control. Thus, we offer our customers a comprehensive and high-quality range of services in the field of transport logistics.

DIN ISO 9001:2015, EMAS and Ecovadis are not foreign words to you? Then it's time to work with the best.

You don't take any risks with us - we have been awarded the Platinum Medal on the EcoVadis sustainability rating platform.

As a load securement company, we are proud to have several certifications that validate our sustainability efforts and our commitment to environmental protection and social responsibility. For you as a purchaser, this means that we demand and promote the implementation of high environmental and social standards both within the company and along the supply chain.

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information