Now 10% off all Ergolash lashing straps save now! Voucher code: ergo10 | Valid until 31.05.2025

In today’s article, I would like to address the topic of big bags. This type of packaging also places demands on the planning and execution of transportation in order to avoid unpleasant surprises. VDI 2700 Sheet 18 has been available as a green print since June 2024.

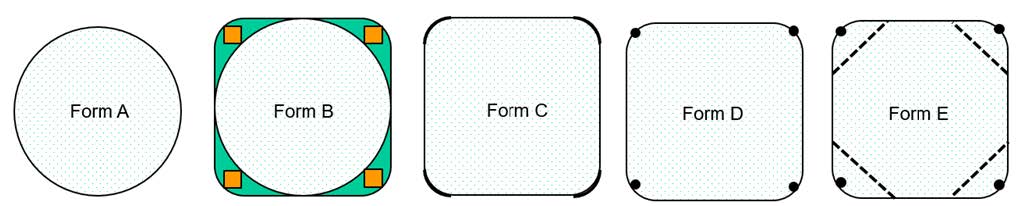

There, the big bag is referred to as an FIBC (Flexible Intermediate Bulk Container). The contents and shape of the FIBC are decisive for how stable the loading unit behaves during transportation. Deformations must always be taken into account. These shapes are defined in the guideline, with shape E made of flat fabric with connections in the corner area being described as the most stable.

Shape A: Simple round fabric

Shape B: Round fabric with pallet-side supports at the corners

Shape C: Flat fabric with reinforced material at the corners

Shape D: Flat weave with corner seams

Form E: Flat weave with corner seams and fabric reinforcements over the corners

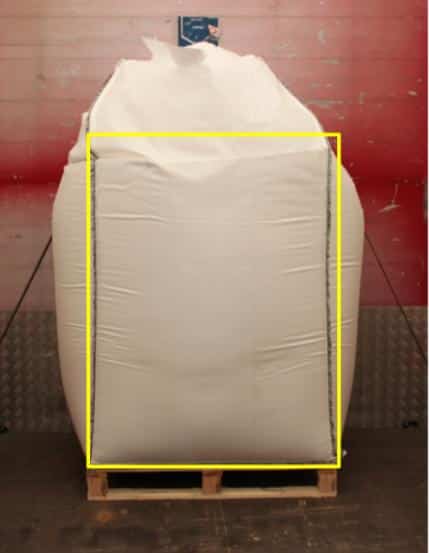

The picture shows an FIBC Form E and it can be seen that it is quite stable on the pallet.

When filling the FIBCs, a mini form closure is created between the pallet boards.

As a result, the FIBCs will not slide off the pallet, but rather tip down if the contents shift or deform.

Of course, this also depends on the grain/particle size of the contents.

The dimensions of the FIBCs can be produced variably. The decisive factor is the means of transportation with which the FIBCs are to be transported. If it is to be a truck, then the Euro pallet grid must be observed in order to achieve the loading width of 2.40 m and thus the tight fit to the sides. If the sea container is the means of transportation, then the loading width of 2.34 m and thus also the pallet dimension of 1.14 m must be taken into account.

So much for the basic ideas. In practice, the first question to be asked is which product is to be packaged, how free-flowing it is and what angle of repose results. The flatter the angle of repose, the more free-flowing the product.

Anyone can test this for themselves by heaping a pound of coffee beans and a pound of flour next to each other. This is easy to do with flour, but not so much with coffee. The more free-flowing the product, the higher the demands on the design of the big bag.

The combination of

If a stable FIBC with adapted dimensions is stowed on/in the means of transport, the effort required to secure the load is comparatively low and may be reduced to the gap to the loading gantry.

If an unstable FIBC with free-flowing contents is placed on an unsuitable load carrier in a less suitable means of transport, the effort required to secure the load is high or inappropriate.

The picture shows a big bag that has already considerably exceeded the dimensions of the pallet before the start of the transportation phase.

Form-fit loading/securing on the truck is therefore no longer possible without further ado. Three bigbags are usually too wide for the loading width of 2.40 m and with two bigbags there is too large a gap to talk about a tight fit.

This picture shows that the frequently used securing method of “lashing down” is not appropriate for big bags because the pre-tensioning force is lost very quickly.

The degree of pre-tensioning force depends on the weight of the load unit. If the pre-tensioning force is lost due to the contents of a big bag giving way to its pressure, the load is considered to be unsecured.

That is exactly the “problem”!

Here, too, you can see how the tension belts sink into the FIBC.

The pre-tensioning force achieved for a short time is lost after a short distance.

This picture shows how the free-flowing load has changed its shape so that part of the FIBC has shifted over the clamping board, which was actually intended to secure the load to the rear.

Here you can see that the FIBCs have closed the existing gaps to the end wall by changing their shape and that the last two/three rows of cargo can no longer be unloaded without considerable effort.

The common denominator of all considerations must be: to keep the free spaces that can be used by the FIBC through deformation as small as possible.

The situation in the picture shows a lot of potential for optimization. Securing with a tensioning strap has little effect.

When planning transportation, it is therefore important to find the optimum combination of transport methods depending on the product to be transported:

The tie-down lashing method has proven to be inappropriate and ineffective in most cases, which is why the focus should be on form-fit lashing.

Measures to increase the coefficient of friction do not necessarily have the usual effect because the load moves in the FIBCs rather than the pallet on the loading surface.

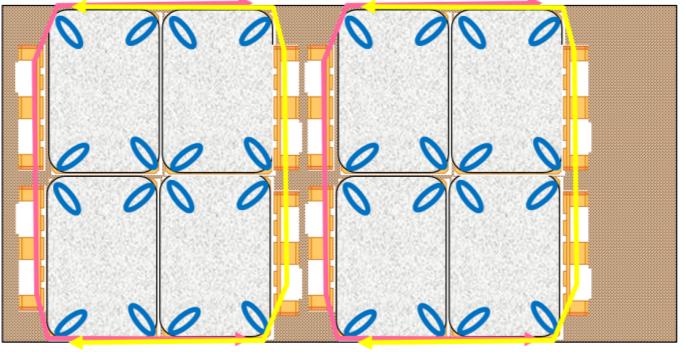

The picture shows that the unfavorable storage direction of the pallets allows unnecessary free space.

In this picture, the same load units have been rotated by 90°, thus significantly reducing the free space. Securing to the side is no longer necessary.

Top view: It can be useful to form a block from several load units, e.g. 4-6 FIBCs.

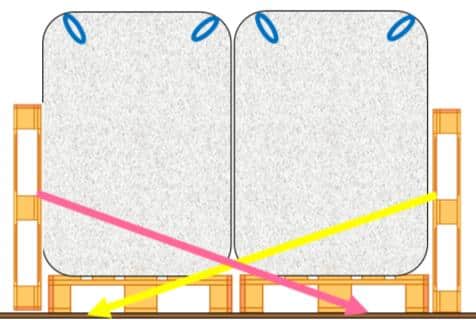

With pallets standing on edge in and against the direction of travel and two tension belts each, the block can be created relatively easily using head lashing.

Side view: The picture shows the belt guide. The crossover guide also restricts lateral movement of the loading unit.

Depending on the load, securing to the rear could also look like this. However, the use of upright pallets for head lashing is the better choice.

In this case, it must of course be clear who is providing or bringing the pallet. If the truck is only in the loading area, it is often too late.

The chosen topic and its many variants are far from exhausted. In any case, the explanations and pictures are intended to show how the problem can be tackled.

VDI-2700 Sheet 18 “Securing bulk goods in flexible packaging” should always be consulted. If necessary, it serves as a basis for the inspection authorities to assess the specific situation.

My explanations are intended to encourage people to take a closer look at this topic and reduce the general risk during the transportation phase for everyone involved.

Get to work!

Yours, Sigurd Ehringer

<< Previous Post

Episode 60: Problem loads part 2: – IBC – What is the solution?

To the next post >>

Sigurd Ehringer

✔ VDI-zertifizierter Ausbilder für Ladungssicherung ✔ Fachbuch-Autor ✔ 8 Jahre Projektmanager ✔ 12 Jahre bei der Bundeswehr (Kompaniechef) ✔ 20 Jahre Vertriebserfahrung ✔ seit 1996 Berater/Ausbilder in der Logistik ✔ 44 Jahre Ausbilder/Trainer in verschiedenen Bereichen —> In einer Reihe von Fachbeiträgen aus der Praxis, zu Themen rund um den Container und LKW, erhalten Sie Profiwissen aus erster Hand. Wie sichert man Ladung korrekt und was sind die Grundlagen der Ladungssicherung? Erarbeitet und vorgestellt werden sie von Sigurd Ehringer, Inhaber von SE-LogCon.

Rothschenk assortment

Our customer center has only one goal: to turn your problems into solutions. Whether standard stowage cushions, bestsellers or load securing personally tailored to your needs -. we accompany you consistently from A as in field service to Z as in certification. That is our promise to you, as a leader in our industry.

We attach great importance to professional cargo securing. That is why we have our own production, which ensures reliable operation through modern manufacturing technologies and strict quality control. Thus, we offer our customers a comprehensive and high-quality range of services in the field of transport logistics.

DIN ISO 9001:2015, EMAS and Ecovadis are not foreign words to you? Then it's time to work with the best.

You don't take any risks with us - we have been awarded the Platinum Medal on the EcoVadis sustainability rating platform.

As a load securement company, we are proud to have several certifications that validate our sustainability efforts and our commitment to environmental protection and social responsibility. For you as a purchaser, this means that we demand and promote the implementation of high environmental and social standards both within the company and along the supply chain.

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information