Now 10% off all Ergolash lashing straps save now! Voucher code: ergo10 | Valid until 31.05.2025

In today’s article, I would like to address the topic of IBCs, as this type of packaging also has its own special problems that need to be taken into account during transportation.

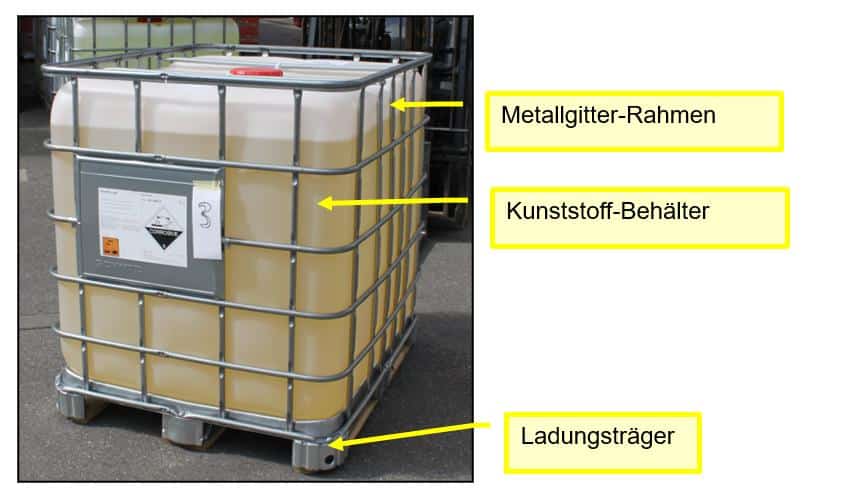

Most people know what an IBC looks like in principle. It is a plastic container in a metal housing, the base of which is designed as a load carrier. There are just as many shapes for the metal grid as there are for the load carrier.

The right variant can be selected depending on the purpose for which it is used.

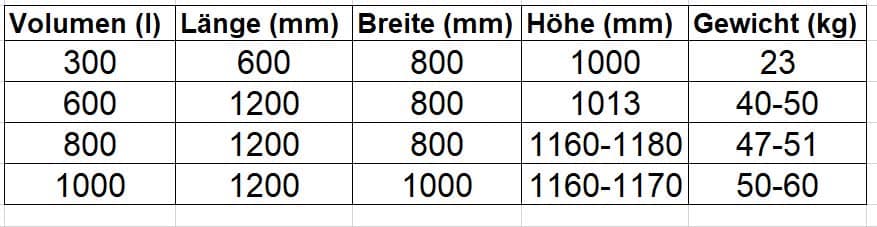

The most common filling volumes are 300, 600, 800 and 1000 liters. The basic dimensions also vary.

This table only shows the standard dimensions.

There may be others depending on the application.

The load carrier becomes a problem load when it has to be stowed and secured on or in a means of transport. The dimensions (LxW) show that they are based on the Euro dimension and can therefore be stowed relatively easily on a truck with a loading width of 2.45m.

But what if the truck or the loading row is not completely full? What to do if a container needs to be stowed and there are gaps? Solutions are needed for this.

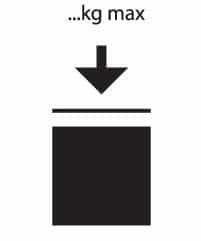

If the IBCs are also permitted for hazardous goods, the permitted stacking load must be marked on the type plate.

This is a surface load that presses evenly and vertically on the lower IBC.

The image, an excerpt from a road test, shows the surge behavior of an IBC that is approx. 90% full.

The lower the fill level, the more critical the situation can become in the event of emergency braking.

The possibility of the IBC toppling over cannot be ruled out.

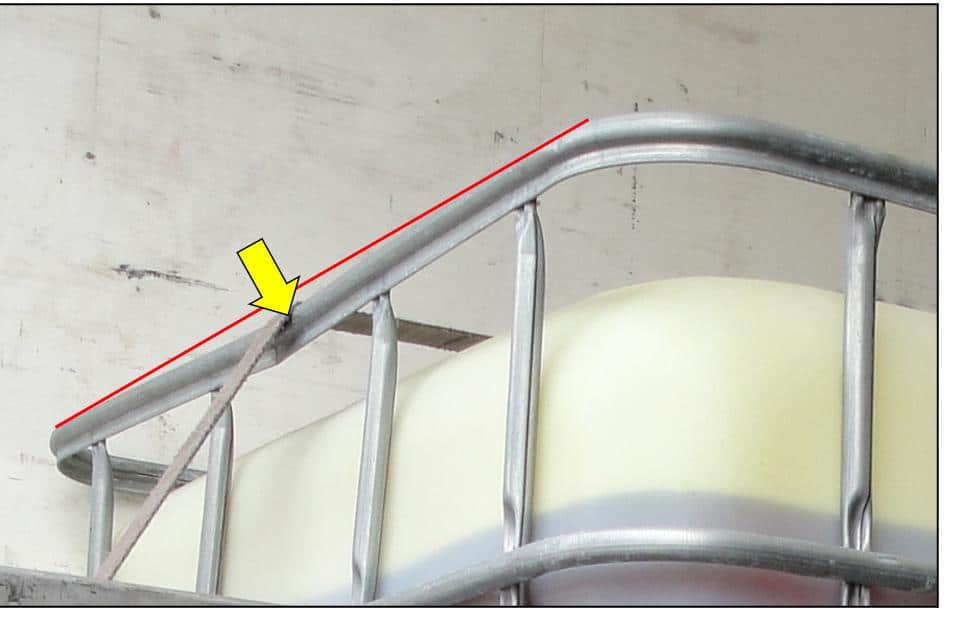

A common method used to secure IBCs is lashing them down. Unfortunately, this solution is only morally correct, but not practically. The pictures show how the IBC deforms when it is lashed down. This starts at a pre-tensioning force of approx. 100daN. Experience shows that the shipper stops tensioning when he sees that the frame is bending.

Guiding the belt via the plastic insert is also not expedient because, like the frame, it gives way and the pre-tensioning force is lost as a result.

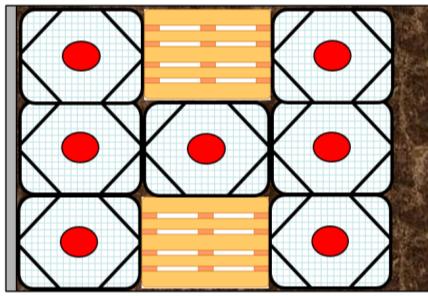

Take the example above and calculate the required or available securing force.

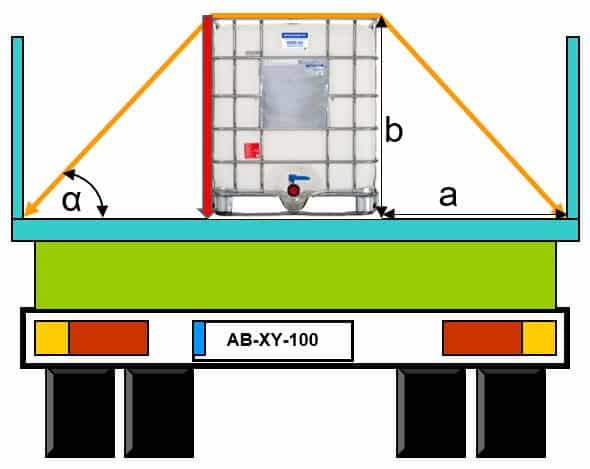

This is what the situation often looks like. The distance a and the height b are important for the angle alpha. This is decisive for the vertical part of the securing force.

Example 1:

Loading width (2.45m-1.0m)/2=0.73m tanα=b/a= 1.17/0.73=1.6027=58°

Example 2:

Loading width (2.45m-0.80m)/2=0.83m tanα=b/a= 1.17/0.83=1.4096=54°

It can already be seen from the example that it makes a difference whether the individual IBC is positioned lengthways or crossways on the loading area, because this changes the angle.

Specifications:

Dimensions: 1.0mx0.80×1.17m

Filling capacity: 1,000 liters

Weight: 1,060 kg

Load carrier: sheet steel;

Friction coefficient; μ=0.2 LT/sieve pressure

Position: in the middle of the loading row

Acceleration 0.5g

Securing force:

1060kgx9.81m/s2x0.5 –

1060kgx9.81m/s2x0.5×0.2 = 520 – 156 = 364daN

In my considerations, I still use the former K-factor from the VDI guidelines, although it has been abolished and replaced by the safety coefficient in the DIN-EN. In the actual loading situation, nobody knows the exact value of either the K-factor or the coefficient of friction on the loading surface.

The safety factor is merely a factor that mathematically increases the securing force on the assumption that it would be sufficient. One uncertainty has been replaced by another uncertainty. The responsible shipper is required to put together a safety package that contains sufficient buffers to cushion the uncertainties.

Every housewife knows not to sew too tightly.

Example 1:

StF x K-factor x μ x sin58° =

100daN x 1.5 x 0.2 x 0.84 = 34daN

Example 2:

StF x K-factor x μ x sin54° =

100daN x 1.5 x 0.2 x 0.80 = 24daN

It is easy to see that too little of the pre-tensioning force remains for the tie-down lashing method to be effective. The only way out would be to place the IBC on anti-slip mats and hold it down to prevent it from moving. Now the pre-tensioning force of 100daN would be sufficient, because the required securing force is provided by the increased frictional force of the anti-slip mats.

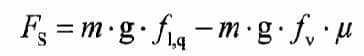

The much more effective method is to recommend positive locking and thus securing through the vehicle body. The body must be verified in accordance with Code XL and be technically sound. This means no damaged stanchions or insertion slats.

For example, the free space between the IBC and the dropside or insertion slats could be filled with two empty pallets.

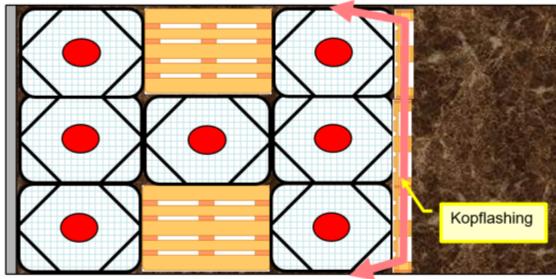

Securing to the rear is achieved by means of locking beams, if available, or with the familiar head lashing via an upright pallet.

If a single IBC cannot be avoided, then it should at least be in the penultimate loading row and not at the end.

The last row of loaders should always be complete so that the safety catch can be fitted effectively to the rear.

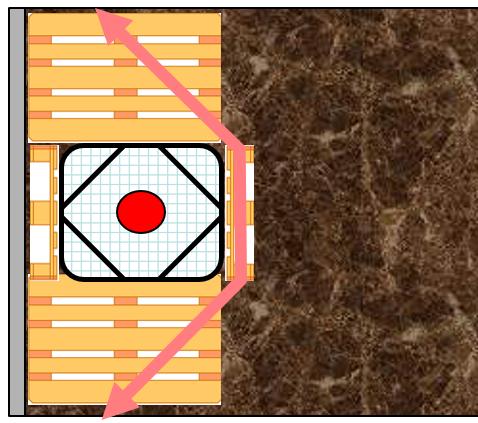

In a container, for example, a 3D dunnage bag would be a conceivable solution to fill the gap on the left and right. The dimensions (LxWxH) of the cushion can be adapted to the situation.

The dunnage bag in the following graphic would replace the pallets.

The loading gap to the container door should be moved one row forward and filled with another dunnage bag.

Securing to the rear could be achieved with classic head lashing using three pallets standing on edge.

Calculated roughly, a belt would provide a securing force of approx. 4,000daN.

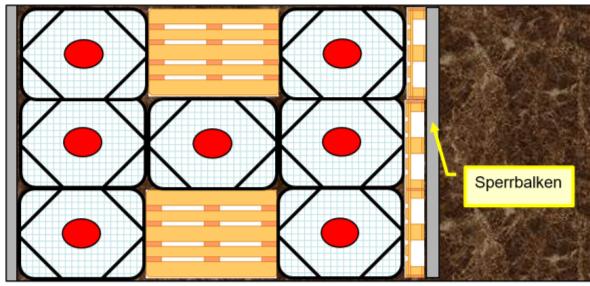

Alternatively, locking beams are preferable. Not to be confused with clamping boards, which are not suitable for this purpose due to insufficient blocking force BC.

Pallets standing on edge should also be used when using locking beams in order to transfer the blocking force of the locking beam to a larger area.

As the above explanations show, the “problem load” IBC can be secured quite sensibly and reliably with comparatively little effort. Only a few considerations are necessary before the truck or container is in the yard and time is of the essence.

As always, my descriptions are only intended to outline the topic, not to cover it exhaustively. If you familiarize yourself with the task, you may find solutions that are simpler and better. Simply doing nothing increases the general risk during the transportation phase for all involved and this should be avoided at all costs.

Get to work!

Yours, Sigurd Ehringer

Sigurd Ehringer

✔ VDI-zertifizierter Ausbilder für Ladungssicherung ✔ Fachbuch-Autor ✔ 8 Jahre Projektmanager ✔ 12 Jahre bei der Bundeswehr (Kompaniechef) ✔ 20 Jahre Vertriebserfahrung ✔ seit 1996 Berater/Ausbilder in der Logistik ✔ 44 Jahre Ausbilder/Trainer in verschiedenen Bereichen —> In einer Reihe von Fachbeiträgen aus der Praxis, zu Themen rund um den Container und LKW, erhalten Sie Profiwissen aus erster Hand. Wie sichert man Ladung korrekt und was sind die Grundlagen der Ladungssicherung? Erarbeitet und vorgestellt werden sie von Sigurd Ehringer, Inhaber von SE-LogCon.

<< Previous Post

Episode 64: Tripwires – the company, the unknown entity

To the next post >>

Rothschenk assortment

Our customer center has only one goal: to turn your problems into solutions. Whether standard stowage cushions, bestsellers or load securing personally tailored to your needs -. we accompany you consistently from A as in field service to Z as in certification. That is our promise to you, as a leader in our industry.

We attach great importance to professional cargo securing. That is why we have our own production, which ensures reliable operation through modern manufacturing technologies and strict quality control. Thus, we offer our customers a comprehensive and high-quality range of services in the field of transport logistics.

DIN ISO 9001:2015, EMAS and Ecovadis are not foreign words to you? Then it's time to work with the best.

You don't take any risks with us - we have been awarded the Platinum Medal on the EcoVadis sustainability rating platform.

As a load securement company, we are proud to have several certifications that validate our sustainability efforts and our commitment to environmental protection and social responsibility. For you as a purchaser, this means that we demand and promote the implementation of high environmental and social standards both within the company and along the supply chain.

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information