Now 10% off all Ergolash lashing straps save now! Voucher code: ergo10 | Valid until 31.05.2025

Acceleration is a physical phenomenon that constantly surrounds us. We often don’t realize it and if we do, it hurts, e.g. when you tap your thumb with a hammer.

With this LaSi blog, I would like to draw a line from everyday situations to special requirements for transportation by sea container or truck.

In physics, we speak of a uniformly accelerated translation with or without initial velocity.

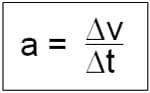

The acceleration (a) is calculated by dividing the speed (v) by the time (t). The acceleration has the unit m/s2.

Changes in speed are often caused by braking, which in physics is referred to as deceleration. The calculation is the same, only the sign changes from + to – .

In practice, there is also the important element of weight/mass. When asked about load securing, some of you have probably already been told that it’s so heavy that it can’t move. And this is precisely where the problem lies, because the mass has the property of wanting to maintain its current state and opposes any change with a force.

Anyone can observe this phenomenon on the conveyor belt of a discount store checkout. The items are moved each time the belt moves forward and slows down. Stacked shopping goods slip, bottles fall over or start to roll. The same thing happens with transportation.

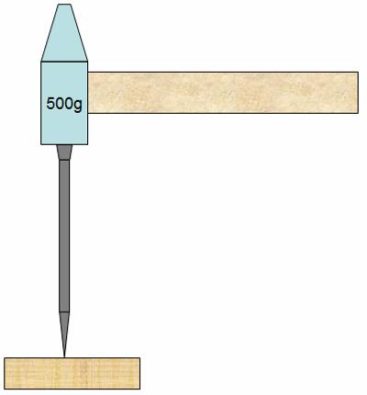

Anyone can test the relationship between mass and acceleration in practice using the following example.

Take a 120mm nail and a 500g hammer. Place the nail with the tip on a block and then place the hammer on the nail head. As a result, the nail will press minimally and insignificantly into the soft wood. If the hammer is removed again, the nail usually falls over again. From a physical point of view, only the force resulting from the weight of the hammer multiplied by the acceleration due to gravity is effective.

The practitioner will lift the hammer, accelerate towards the nail head and hopefully hit it. This additional acceleration significantly increases the force generated:

Force (F) = mass (m) * acceleration (a)

On impact, the hammer is abruptly decelerated and the force drives the nail into the wood. Depending on the acceleration, the weight of the hammer and the friction in the wood, several blows will be required.

Depending on the situation, the practitioner will use a different hammer to generate the required force. Of course, it also requires a certain amount of technology. Anyone who has ever hit the “Lukas” knows what I’m talking about.

This basic principle is hidden behind many situations in load securing. For example, if a load is not stowed tightly against the bulkhead and the truck driver has to brake. The load is traveling at the current speed (phase 2) and is activated during braking (phase 3) negatively accelerated. The greater the speed and the longer the distance over which it can gain momentum, the greater the force of the impact on the front wall.

In physical terms, this is expressed using the formula for calculating energy. This formula also contains the speed squared(V2).

Perhaps some of you remember a question from your driving license days: How does the braking distance change when the speed doubles?

Answer: it quadruples . This is due to the speed squared. This means that the energy (impact force on the front wall) also increases with the speed traveled.

Cargo always moves when the acceleration/deceleration is greater than the friction (coefficient of friction µ). This means that as long as the acceleration/deceleration is less than the friction between the load and the loading surface, the load remains in place. Only when they become larger does the load move jerkily.

As a rule, there is no gradual transition. However, load units at risk of tipping first start to tip and then slide. This can be demonstrated well with road tests.

This example clearly shows that anti-slip mats alone are only a theoretical improvement in load securing. They must be supplemented by additional measures such as lashing down.

A stack of plastic boxes stands on the loading area without any additional securing.

When braking, they slide forward without tilting.

To additionally secure the load, the boxes were placed on anti-slip mats.

When braking, they immediately start to tip over.

It is therefore important to prevent cargo from moving. The form fit is the simplest solution. However, it should be noted that the movement of the charge must be prevented in all directions, as movement in the direction of acceleration/deceleration is usually followed by a reaction in the opposite direction. Sometimes the load securing to the rear is called into question.

The main part of this backward acceleration comes as a reaction to emergency braking (rebound effect), because the energy inherent in the load is not completely used up.

The following is an example from a road test. The load weighs approx. 1,200 kg, the speed approx. 25 km/h.

After a 5-second video runtime, the vehicle brakes fully from 25 km/h and the 1,200 kg load tips forwards because it was not stowed positively against the lattice box.

Immediately afterwards, the movement (rebound effect) takes place backwards. Only 2 seconds later, the load has almost completely tipped over because the kinetic energy was not fully dissipated during the emergency braking.

This is why loads must also be secured to the rear.

In truck transportation, this process – emergency braking at 0.8 g – usually only takes place once. During transportation by container ship, which can also achieve an acceleration of 0.8 g when rolling, this movement can occur 2-3 times per minute. These permanent accelerations are one of the special features of the container.

The responsible loader/stevedore is therefore required to assess the specific situation on the truck or in the container, estimate or calculate the forces and then take the necessary measures. Gap fillers must of course be able to withstand the permanent load. For example, cardboard spacers are rather unsuitable in damp environments.

Safety measures, in order of effectiveness, are:

Yours, Sigurd Ehringer

<< Previous post

Episode 8: Positive locking in the container

Next post >>

Episode 10: Force closure

Sigurd Ehringer

✔ VDI-zertifizierter Ausbilder für Ladungssicherung ✔ Fachbuch-Autor ✔ 8 Jahre Projektmanager ✔ 12 Jahre bei der Bundeswehr (Kompaniechef) ✔ 20 Jahre Vertriebserfahrung ✔ seit 1996 Berater/Ausbilder in der Logistik ✔ 44 Jahre Ausbilder/Trainer in verschiedenen Bereichen —> In einer Reihe von Fachbeiträgen aus der Praxis, zu Themen rund um den Container und LKW, erhalten Sie Profiwissen aus erster Hand. Wie sichert man Ladung korrekt und was sind die Grundlagen der Ladungssicherung? Erarbeitet und vorgestellt werden sie von Sigurd Ehringer, Inhaber von SE-LogCon.

Rothschenk assortment

Our customer center has only one goal: to turn your problems into solutions. Whether standard stowage cushions, bestsellers or load securing personally tailored to your needs -. we accompany you consistently from A as in field service to Z as in certification. That is our promise to you, as a leader in our industry.

We attach great importance to professional cargo securing. That is why we have our own production, which ensures reliable operation through modern manufacturing technologies and strict quality control. Thus, we offer our customers a comprehensive and high-quality range of services in the field of transport logistics.

DIN ISO 9001:2015, EMAS and Ecovadis are not foreign words to you? Then it's time to work with the best.

You don't take any risks with us - we have been awarded the Platinum Medal on the EcoVadis sustainability rating platform.

As a load securement company, we are proud to have several certifications that validate our sustainability efforts and our commitment to environmental protection and social responsibility. For you as a purchaser, this means that we demand and promote the implementation of high environmental and social standards both within the company and along the supply chain.

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information