Home page » Product protection » protective covers

protective covers

Load securing directly from the manufacturer

- Individually printable tarpaulins

- Stable pressure ratchet fastening

- Integrated strapping solution

- Quality Made in Germany

Rothschenks protective covers

Innovative design according to customized wishes

protective covers play a crucial role in protecting packages during transportation or storage by protecting them from environmental influences and soiling. Our protective covers are made from high-quality, dirt-repellent tarpaulin and are individually adapted to the customer’s specific requirements in our own production facility in Germany. The use of high-quality Velcro or webbing straps with sewn-on ratchets makes attaching the hoods much easier and ensures efficient handling.

In addition, we offer the option of personalizing the protective covers with advertising banners to create not only protection but also a visual presence for your brand.

Examples of the use of protective covers

As short-term weather protection, we manufacture protective covers against weathering and environmental influences at the customer’s request. We can produce these from PP fabric or from various types of tarpaulin fabric.

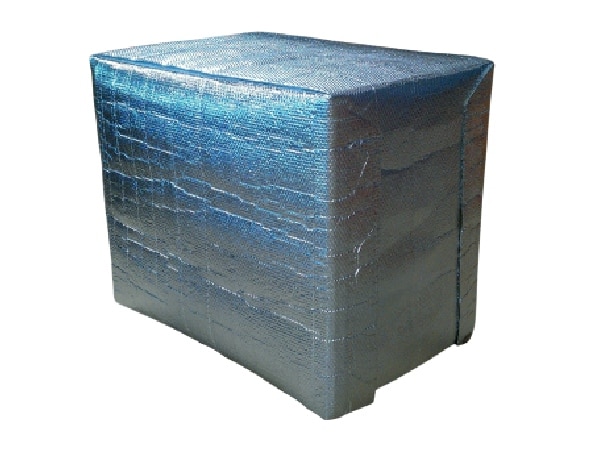

Insulating, aluminum-coated fabric for temperature-controlled transport or to prevent a serious change in temperature during transport of the goods.

Custom-made protective covers e.g. for metal racks, used clothing containers or mesh boxes. Made of various materials for reusable use.

Tarpaulin that is strapped around the goods to secure smaller packages and stabilize the transport frame.

Our pipe bag is used for storing and transporting pipes.

It is slipped over the ends and secured with a clamp buckle strap to prevent foreign matter from entering.

Large machine parts must be specially protected during transportation. In the example opposite, the gearbox of a wind turbine was fitted with protective covers.

Did you know?

With our production facilities in Germany, we can pool all our know-how.

This enables us to respond to customer requests in the shortest possible time and maintain maximum delivery capability

We will be happy to advise you.

protective covers FAQ

Frequently asked questions

For professional cleaning of protective covers, it is always advisable to follow the manufacturer’s instructions. In practice, however, it has proven to be best to work with mild soapsuds before using more intensive cleaners.

protective covers can have very different material properties depending on the intended use. If they are only used as dust protection indoors, a PE film is often sufficient.

However, if outdoor goods are to be protected from dirt and the effects of the weather, more robust materials such as PVC or PVC-coated fabric are chosen.

If the cover is to meet thermal requirements, it may be necessary to use insulating, e.g. aluminum-coated films with air cushions. This makes it possible to protect temperature-controlled transports from temperature loss during loading and unloading.

The UV resistance of materials is an often underestimated property in the outdoor sector. To avoid damage to the goods to be covered, the UV protection should be adapted to the weather conditions.

Otherwise, cracks may form or the material may weaken, which can severely impair the protective function of a cover. Moisture damage can also occur under the cover, which cannot be detected from the outside at first.

The manufacturer can provide reliable information about the UV stability of the materials used.

A reliable statement about the tensile strength of a material used at protective covers can be made after appropriate tests. For this purpose, material samples are subjected to cyclic load tests. These vary in intensity and environmental factors, such as temperature.

After processing into a cover, other factors such as the seam pattern used or the design of the cover play a role.

Do you have any questions about protective covers?

Send us a message

Industriestrasse 5 & 7-10

97239 Aub, Germany

Service hours:

Mon - Thu | 8:00 am - 5:00 pm Fri | 8:00 am - 1:00 pm Collection/delivery: Mon - Fri | 7:00 am - 3:00 pm

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information