Now 10% off all Ergolash lashing straps save now! Voucher code: ergo10 | Valid until 31.05.2025

The form-fit securing of the load has already been described in episode 8 has already been dealt with. Now let’s take a closer look at the frictional connection . What is meant by adhesion, how does it work and what is important when securing loads?

A frictional connection is a connection of two parts via the surface, whereby both surfaces have a high coefficient of friction. How does it work?

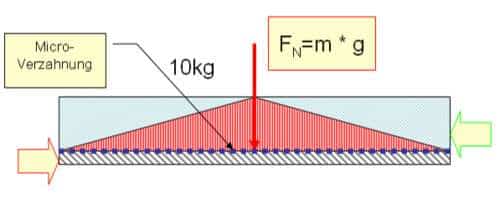

A load presses on a surface with an assumed 10 kg. The normal force is calculated by multiplying the mass (example 10 kg) by the gravitational force g (9.81 m/s2).

The normal force is therefore 10 kg * 9.81 m/s2= 100 N.

The normal force always acts vertically on the surface.

Each surface has a certain roughness, which creates a micro-serration when the two surfaces come into contact. The dimension is indicated by the letter µ and is called the coefficient of friction.

If an attempt is now made to move the surfaces against each other, this roughness creates a counterforce. It is precisely this effect that is used in force closure .

The counterforce depends on the specific coefficient of friction µ and is referred to as the frictional force.

If, for example, a manufacturer of truck bodies specifies a coefficient of friction of µ=0.3 for its loading surfaces, this means that the force required to move pallets is 30% of the normal force.

How does the force-locking securing of a free-standing load of 1,000 kg against displacement during full braking at 0.8 g work? (see VDI-2700 and EN-12195-1).

The required securing force according to the regulations is

FS = m * g * a = 1,000 kg * 9.81 m/s2 * 0.8 g = 8,000 N = 800 daN

A load is usually lashed down with tension belts. The force that now counteracts the displacement now consists of two components: the normal force + the preload force.

However, the influence of three boundary conditions must be taken into account:

The pre-tensioning force can also be understood as an additional load weight. This means that only the portion of the preload force corresponding to the coefficient of friction is effective.

Frictional forceFR = 1,000 daN * 0.3 = 300 daN

Securing force FS = 500 daN * 0.3 = 150 daN

Total: 450 daN

A force of only 450 daN would therefore be required to move 1,000 kg.

The example shows that the pre-tensioning force of 500 daN is not sufficient to secure the load against shifting. measures such as lashing down.

Another boundary condition for the size of the effective pre-tensioning force is the lashing angle α, because only the vertical part of the pre-tensioning force is effective. The proportion results from the sine of the lashing angle.

Example: with a lashing angle α of 80º, the sine is 0.9961.

This means that of the 500 daN pre-tensioning force, only 500 daN * 0.9961 = 498 daN is actually effective

The pre-tensioning force generated by the tensioning ratchet only exists between the attachment point on the loading surface and the 1st deflection point. It is reduced at the deflection points due to friction losses. The more deflection points, the greater the loss.

The sum of the preload force is therefore made up of at least three parts:

The result can be calculated using the transmission coefficient/K-factor. Assuming a factor of 1.5, the sum of the pre-tensioning force would be 500 daN * 1.5 = 750 daN.

If all boundary conditions are now considered together following the example, the following calculation results:

FSTF = pre-tensioning force * K-factor * sin lashing angle α * µ

= 500 daN * 1.5 * sin35º (0.5735) * 0.3 = 129 daN

How many lashing straps are needed to secure this load? The following consideration can be made here:

800 daN must be secured, subtract the friction force of 450 daN from this and the difference is 350 daN. This force must be provided by tension belts . 350 daN divided / 129 daN = 2.7 which means that 3 lashing straps are required to secure the load of 1,000 kg under the specified boundary conditions.

The conclusion is frightening, because of 500 daN, which is a lot in itself, there is actually very little left. This should lead to the conclusion that the friction-locked securing method of tie-down lashing is subject to many constraints and must therefore be used with the utmost caution.

A general solution is the combination of tie-down lashing + anti-slip mats with µ=0.6.

Increasing the coefficient of friction is the decisive element.

Frictional forceFR = 1,000 daN * 0.6 = 600 daN

Prestressing force FSTF = 500 daN * 1.5 * sin35º (0.5735) * 0.6 = 258 daN

Securing forceFS = 600 daN + 258 daN = 858 daN

Securing balance: the actual securing force must be equal to or greater than the required securing force. 858 daN ≥ 800 daN

In practice, you often see exactly the opposite. Presumably due to a lack of knowledge of the principle of action.

Yours, Sigurd Ehringer

<< Previous post

Episode 9: Accelerations

Next post >>

Episode 11: Stowage planning in a container

Sigurd Ehringer

✔ VDI-zertifizierter Ausbilder für Ladungssicherung ✔ Fachbuch-Autor ✔ 8 Jahre Projektmanager ✔ 12 Jahre bei der Bundeswehr (Kompaniechef) ✔ 20 Jahre Vertriebserfahrung ✔ seit 1996 Berater/Ausbilder in der Logistik ✔ 44 Jahre Ausbilder/Trainer in verschiedenen Bereichen —> In einer Reihe von Fachbeiträgen aus der Praxis, zu Themen rund um den Container und LKW, erhalten Sie Profiwissen aus erster Hand. Wie sichert man Ladung korrekt und was sind die Grundlagen der Ladungssicherung? Erarbeitet und vorgestellt werden sie von Sigurd Ehringer, Inhaber von SE-LogCon.

Rothschenk assortment

Our customer center has only one goal: to turn your problems into solutions. Whether standard stowage cushions, bestsellers or load securing personally tailored to your needs -. we accompany you consistently from A as in field service to Z as in certification. That is our promise to you, as a leader in our industry.

We attach great importance to professional cargo securing. That is why we have our own production, which ensures reliable operation through modern manufacturing technologies and strict quality control. Thus, we offer our customers a comprehensive and high-quality range of services in the field of transport logistics.

DIN ISO 9001:2015, EMAS and Ecovadis are not foreign words to you? Then it's time to work with the best.

You don't take any risks with us - we have been awarded the Platinum Medal on the EcoVadis sustainability rating platform.

As a load securement company, we are proud to have several certifications that validate our sustainability efforts and our commitment to environmental protection and social responsibility. For you as a purchaser, this means that we demand and promote the implementation of high environmental and social standards both within the company and along the supply chain.

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information