Now 10% off all Ergolash lashing straps save now! Voucher code: ergo10 | Valid until 31.05.2025

The anti-slip mat is often seen as a panacea in load securing, but is it really? However, the many observations I have been able to make during loading often reveal a completely different picture in practice. It is often “made worse”.

The how and what will be explained below.

First of all, the functional principle of anti-slip mats (ARM) will be described.

There is a coefficient of friction between all surfaces due to their roughness. How high this is depends on the respective combination of materials. VDI-2700 and EN-12195-1 have defined standard values in tables that can usually be used.

In practice, however, the shipper must always assess which coefficient of friction he is assuming in order to determine the necessary securing measures. For example, a coefficient of friction µ=0.3 is assumed for Euro pallets on a truck bed with a screen-printed floor. This means that the securing force from friction is 30% of the load weight.

Anti-slip mats are generally assumed to have a coefficient of friction of µ=0.6, which results in a doubling of the frictional force to 60% of the load weight. So much for the theory.

Unfortunately, the reality is often completely different. When determining friction coefficients, it is always assumed that there is nothing else between the friction partners. This is the crux of the matter, because we often find dirt, grime and other materials in between.

When two surfaces touch, the normal force (FN) creates micro-serrations that generate resistance to displacement (Fx,y). This creates a frictional force (FR) that counteracts this.

The coefficient of friction is calculated by dividing the displacement force Fx,y by the normal force FN. The result is a factor, the coefficient of friction µ. It is without a unit because mathematically the unit Newton (N) of the forces Fx,y and FN is shortened when dividing.

If the load were to become heavier under the same circumstances, the displacement force would also increase and thus the ratio of forces and the coefficient of friction µ would remain the same.

This is also the reason why two loads of different weights start moving almost simultaneously when braking. This is a good experiment for load securing training.

This ratio is also the reason why the area does not play a role, at least in theory, because it would also be reduced when calculating.

If anti-slip mats (ARM) are used, they fill the gaps between the micro-serrations and a mini form fit is created. This increases the displacement force and results in a higher coefficient of friction.

The coefficient of friction of anti-slip mats, according to VDI-2700 Sheet 14, is generally assumed to be µ=0.6.

An essential prerequisite for the optimum effect of frictional forces is a swept-clean loading surface. It must be swept off before each charging process so that, if possible, only the two friction partners, e.g. loading area and pallet runners come into contact with each other.

If anti-slip mats are used, only then will they develop their optimum effect.

The situations described below should help you to make optimum use of the effect of the friction force and avoid errors or misjudgements.

One mistake you often see is that the anti-slip mats are only laid along the edges of the loading area, while there are no mats in the middle. Sometimes they are only placed on the police side, on the left in the direction of travel.

The effect is that the assumed coefficient of friction of µ=0.6 is not achieved under any circumstances. Depending on the situation, the supervisory authority may not include ARMs in the calculation because they are deemed ineffective.

The anti-slip pads are too small and too thin. This also leads to a reduction in friction because the pallet runner is not completely separated from the loading surface. The larger part of the skid is in contact with the loading area.

The middle runner is often not set to ARM. This can work with stable Euro pallets in combination with thick ARM (> 10 mm) and full-surface load distribution.

However, this is not the case with industrial or disposable pallets (image on the right). Whole strips must be placed underneath in order to achieve a coefficient of friction of µ=0.6.

The same unfavorable effect is achieved if the ARMs are placed crosswise under the pallet skid, even though the strip would be long enough.

The larger part of the pallet base is in contact with the loading surface. The shipper/driver has given away the potential benefit of the anti-slip mats.

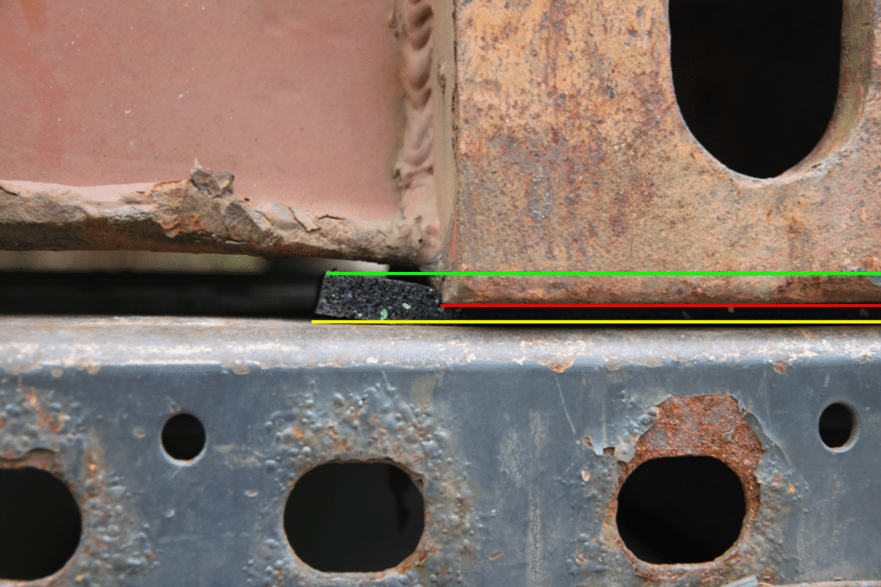

The feet of loading frames are a general problem, regardless of their intended use, especially if they are not closed at the bottom.

During transportation, the omnipresent acceleration rubs through the mats, the base of the frame stands up on the loading area and the friction-enhancing effect is gone.

For practical use with a wide range of requirements, the anti-slip mats should be at least 8 mm thick, preferably 10 mm, so that the load carrier can be separated from the loading area with little effort.

The aim must always be to move the load away from the loading area. This is why ARM strips are better than ARM pads, because they are more efficient to lay. In the picture on the right, the next pallet can already be placed on the laid strip.

The 200x800x8mm dimension is a good compromise that can be used to solve many congestion situations.

The picture shows how badly the ARM is deformed. A deformation/compression of max. 30% of the mat thickness. That was far exceeded here.

Heavy-duty mats would be required for this application, containers on a flatbed. The same would apply to machines and systems if the contact surface were to generate excessive surface pressure.

If the load is at risk of tipping, it must be remembered that the tipping process starts much more quickly, not to say immediately, with anti-slip mats. This is another reason to secure loads additionally by lashing them down or directly.

To ensure that the anti-slip mats remain effective throughout transportation, the load must be additionally secured by holding it down. Holding down means a pre-tensioning force of approx. 150-200 daN, which compensates for vertical accelerations that would result in a reduction of the frictional force.

The vertical force component of direct lashings also achieves this as long as the lashing angles α are not less than 15º.

Yours, Sigurd Ehringer

<< Previous post

Episode 11: Stowage planning in a container

Next post >>

Episode 13: Securing the container door

Sigurd Ehringer

✔ VDI-zertifizierter Ausbilder für Ladungssicherung ✔ Fachbuch-Autor ✔ 8 Jahre Projektmanager ✔ 12 Jahre bei der Bundeswehr (Kompaniechef) ✔ 20 Jahre Vertriebserfahrung ✔ seit 1996 Berater/Ausbilder in der Logistik ✔ 44 Jahre Ausbilder/Trainer in verschiedenen Bereichen —> In einer Reihe von Fachbeiträgen aus der Praxis, zu Themen rund um den Container und LKW, erhalten Sie Profiwissen aus erster Hand. Wie sichert man Ladung korrekt und was sind die Grundlagen der Ladungssicherung? Erarbeitet und vorgestellt werden sie von Sigurd Ehringer, Inhaber von SE-LogCon.

Rothschenk assortment

Our customer center has only one goal: to turn your problems into solutions. Whether standard stowage cushions, bestsellers or load securing personally tailored to your needs -. we accompany you consistently from A as in field service to Z as in certification. That is our promise to you, as a leader in our industry.

We attach great importance to professional cargo securing. That is why we have our own production, which ensures reliable operation through modern manufacturing technologies and strict quality control. Thus, we offer our customers a comprehensive and high-quality range of services in the field of transport logistics.

DIN ISO 9001:2015, EMAS and Ecovadis are not foreign words to you? Then it's time to work with the best.

You don't take any risks with us - we have been awarded the Platinum Medal on the EcoVadis sustainability rating platform.

As a load securement company, we are proud to have several certifications that validate our sustainability efforts and our commitment to environmental protection and social responsibility. For you as a purchaser, this means that we demand and promote the implementation of high environmental and social standards both within the company and along the supply chain.

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information