Now 10% off all Ergolash lashing straps save now! Voucher code: ergo10 | Valid until 31.05.2025

Opening a container is always an exciting experience for everyone. The inspection authorities know from experience that opening can sometimes have unpleasant consequences.

To prevent this, they always take precautions to ensure that the door can be opened safely. In my experience, there are two types of shippers.

Some create a danger for those who open the doors because they don’t know any better and others consciously accept this danger. For example, if the container is fumigated and not labeled. My focus is on the shipper group, which doesn’t know any better, and I want to change that.

The CTU code stipulates that the door must always be safe to open. This principle must run through all considerations.

The load securing to the container door may have to fulfill two tasks

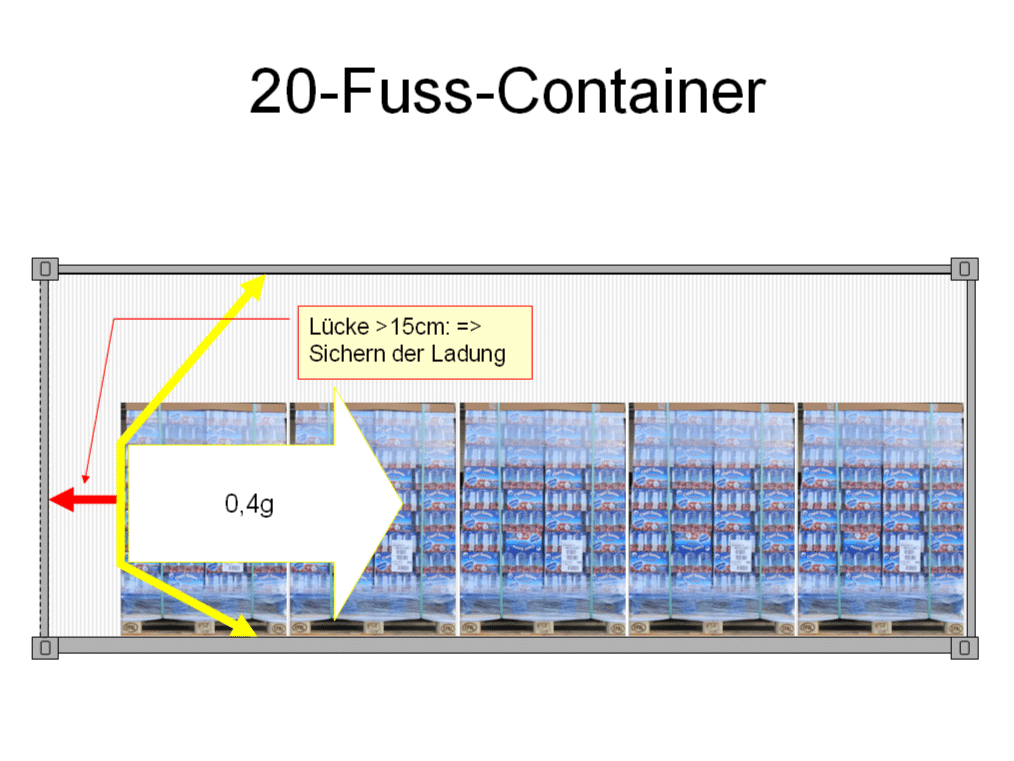

If the distance between the load and the door is more than 15 cm, the securing method (e.g. lashings) must secure the load against the usual transportation loads (sea transport 0.4 g). At the same time, this provides protection against falling out.

If the distance is less than 15 cm, the door secures the load against the usual transportation loads (sea transport 0.4 g) and only securing the load against falling out is required.

What methods are there to secure the load if the distance to the door is greater than 15 cm and this distance cannot be reduced in any other way?

The classic method is bracing. The forces should not, as in this example, be applied to the corrugations, but to the corner posts. Fixing the crosspieces in the beads is an indeterminate method because there is no reliable information on the forces that can be transmitted.

If there are tests with repeatable results for a specific case, that would be acceptable. Otherwise avoid this method.

H or double H securing used to be a common method because it could be produced with running belt material.

However, its effectiveness is rather controversial today because it is difficult to produce correctly and requires a lot of practice.

Professionally produced lashings with up to 4 cross straps are the common method today.

In the variant in the picture, the height of the cross straps can be variably adjusted to the load.

There are also a number of now standardized methods for securing against falling out.

Safety tarpaulin, combined with a flat dunnage bag. The crossed straps prevent the door from dunnage bag pressure against the door.

The S.A.M. system consists of two stowage cushions connected by a tarpaulin. The outer sides of the pads can have an anti-slip coating to provide greater frictional force. This system has proved particularly effective for refrigerated containers.

The TyPatch system is a method that is suitable for uniform and dimensionally stable load units. As this is a system that works like an adhesive tape, it is important to pay particular attention to the manufacturer’s instructions for use and application. In particular, the bonding surfaces must be dust-free and dry.

The above examples are not final and conclusive; there are certainly many company-specific variants.

The responsible stevedore must in any case ensure that the general requirements of the CTU Code are implemented correctly and sufficiently so that there are no complaints, delays or fines during inspections.

Yours, Sigurd Ehringer

<< Previous post

Episode 12: How does a anti-slip mat work?

Next post >>

Episode 14: Misjudgements when securing loads

Sigurd Ehringer

✔ VDI-zertifizierter Ausbilder für Ladungssicherung ✔ Fachbuch-Autor ✔ 8 Jahre Projektmanager ✔ 12 Jahre bei der Bundeswehr (Kompaniechef) ✔ 20 Jahre Vertriebserfahrung ✔ seit 1996 Berater/Ausbilder in der Logistik ✔ 44 Jahre Ausbilder/Trainer in verschiedenen Bereichen —> In einer Reihe von Fachbeiträgen aus der Praxis, zu Themen rund um den Container und LKW, erhalten Sie Profiwissen aus erster Hand. Wie sichert man Ladung korrekt und was sind die Grundlagen der Ladungssicherung? Erarbeitet und vorgestellt werden sie von Sigurd Ehringer, Inhaber von SE-LogCon.

Rothschenk assortment

Our customer center has only one goal: to turn your problems into solutions. Whether standard stowage cushions, bestsellers or load securing personally tailored to your needs -. we accompany you consistently from A as in field service to Z as in certification. That is our promise to you, as a leader in our industry.

We attach great importance to professional cargo securing. That is why we have our own production, which ensures reliable operation through modern manufacturing technologies and strict quality control. Thus, we offer our customers a comprehensive and high-quality range of services in the field of transport logistics.

DIN ISO 9001:2015, EMAS and Ecovadis are not foreign words to you? Then it's time to work with the best.

You don't take any risks with us - we have been awarded the Platinum Medal on the EcoVadis sustainability rating platform.

As a load securement company, we are proud to have several certifications that validate our sustainability efforts and our commitment to environmental protection and social responsibility. For you as a purchaser, this means that we demand and promote the implementation of high environmental and social standards both within the company and along the supply chain.

G&H GmbH Rothschenk

Industriestrasse 5 & 7-10

97239 Aub

Phone: +49 9335 97 15 – 79

Fax: +49 9335 97 15 – 15

E-mail: info@rothschenk.de

Collection/delivery

Mon – Fri: 8:00 – 15:00

Office hours

Mon – Thu: 8:00 – 17:00

Fri: 8:00 – 13:00

G&H GmbH Rothschenk

Industriestrasse 5 & 7-10

97239 Aub

Phone: +49 9335 97 15 – 0

Fax: +49 9335 97 15 – 15

E-mail: info@rothschenk.de

Collection/delivery

Mon – Fri: 8:00 – 15:00

Office hours

Mon – Thu: 8:00 – 17:00

Fri: 8:00 – 13:00

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information