With Rothschenk, you can be sure of receiving absolute professional quality. We have thus cemented our reputation in the industry and will not deviate from this principle. Leave a lasting impression on your customers. With a print on your lashing strap, you show the world that you are serious about professional load securing. In addition, you can immediately see whether it is your own lashing strap, the quality of which you know. We would be happy to advise you and print your webbing according to your ideas. Request a non-binding quote now.

Startseite » TRUCK » Lashing straps

Lashing straps

Proven classic in load securing

- Flexible everyday helper

- Robust design

- DIN EN 12195-2 certified

- Quality Made in Germany

Proven load securing

Pressure ratchet

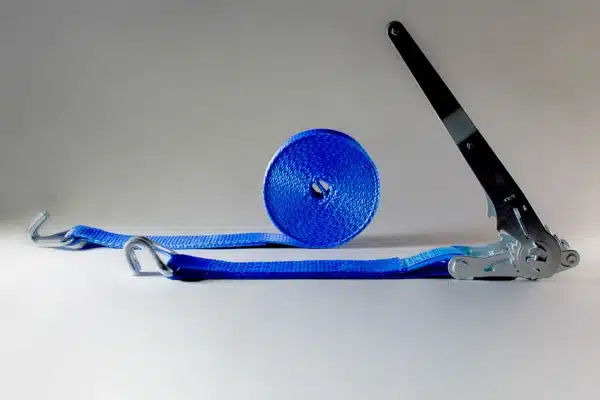

Pressure ratchets consist of a short part, the fixed end with a pointed hook and the tensioning unit, the metal ratchet.

This works on “pressure”, i.e. the user tensions the threaded loose end by “opening” the ratchet. This is where the name pressure ratchet for this lashing strap comes from.

Further information on pressure ratchets

Pressure ratchets are the tried and tested method of tensioning lashing straps to secure goods to the loading area. Our range includes different belt widths and lengths, as well as tensile strengths. Top value for money, our printing ratchets secure your goods in professional quality. As a manufacturing company for load securing, we have testing facilities that enable us to define the quality of our goods according to specific criteria.

- Cost-effective load securing

- High quality

- user-friendly

- individually printable

- Various lengths and designs

- Webbing material: PES

- Material fittings: FE

- certified according to EN 12195-2

Lashing straps for truck load securing

Quick and secure attachment to the loading area

Lashing straps are the tried and tested classic in load securing – ideal for lashing down goods in trucks or vans. Available in many versions, e.g. as a robust push ratchet or ergonomic long lever pull ratchet .With the two-part lashing straps made of polyester fabric and with pointed hooks, you can secure your load on trucks and transport vehicles quickly and easily . Our lashing straps are also equipped with high-quality, solid ratchets. For your load securing, you can choose between pressureratchet or ergonomic long-lever pull ratchet.

Ergonomic load securing

Long lever pull ratchet

Long lever ratchets have a fixed end where the lever is extended for tensioning. As a result, the leverage for the user is higher and less manual force is required to achieve the desired pre-tensioning force.

In addition, the long lever ratchet, also known as an ergo ratchet, works on “pull”, which means that the tension is generated from the loose end when the ratchet is “closed”.

There is a major ergonomic advantage when used on a truck if the loader wants to tension at eye level or higher while standing next to the vehicle. Thanks to the special design, he does not have to push upwards away from himself, but can pull downwards with his body weight.

Further information on (Ergo) long lever pull ratchets

Little things often make everyday life a lot easier. This is also the case with our “Ergo” long lever pull ratchet. The extended lever handle makes it much easier to achieve the manual force of 50 daN to be applied. In contrast to a classic pressure ratchet, the longer leverage makes everyday work much easier.

Conventional pressure ratchets clamp with an upward movement of the lever. Long-lever pull ratchets, on the other hand, are actuated downward. Since this is much more conducive to ergonomics, there are tangible advantages. Power transmission is significantly increased and securing the load can be done more easily.

The user can achieve the necessary pretensioning forces with much less strain on his back thanks to the extended lever in combination with the easier operation. We are also happy to customize your lashing strap, e.g. with your company slogan or logo.

- Much easier to use

- Higher preload forces

- Pull ratchet instead of push ratchet

- Extended handle

- Higher leverage

- Webbing material: PES

- Material fittings: FE

- certified according to EN 12195-2

Lashing straps from Rothschenk

Our product recommendations for you

-

- Select options This product has multiple variants. The options may be chosen on the product page

-

-

- Select options This product has multiple variants. The options may be chosen on the product page

-

-

- Select options This product has multiple variants. The options may be chosen on the product page

-

-

- Select options This product has multiple variants. The options may be chosen on the product page

-

- Select options This product has multiple variants. The options may be chosen on the product page

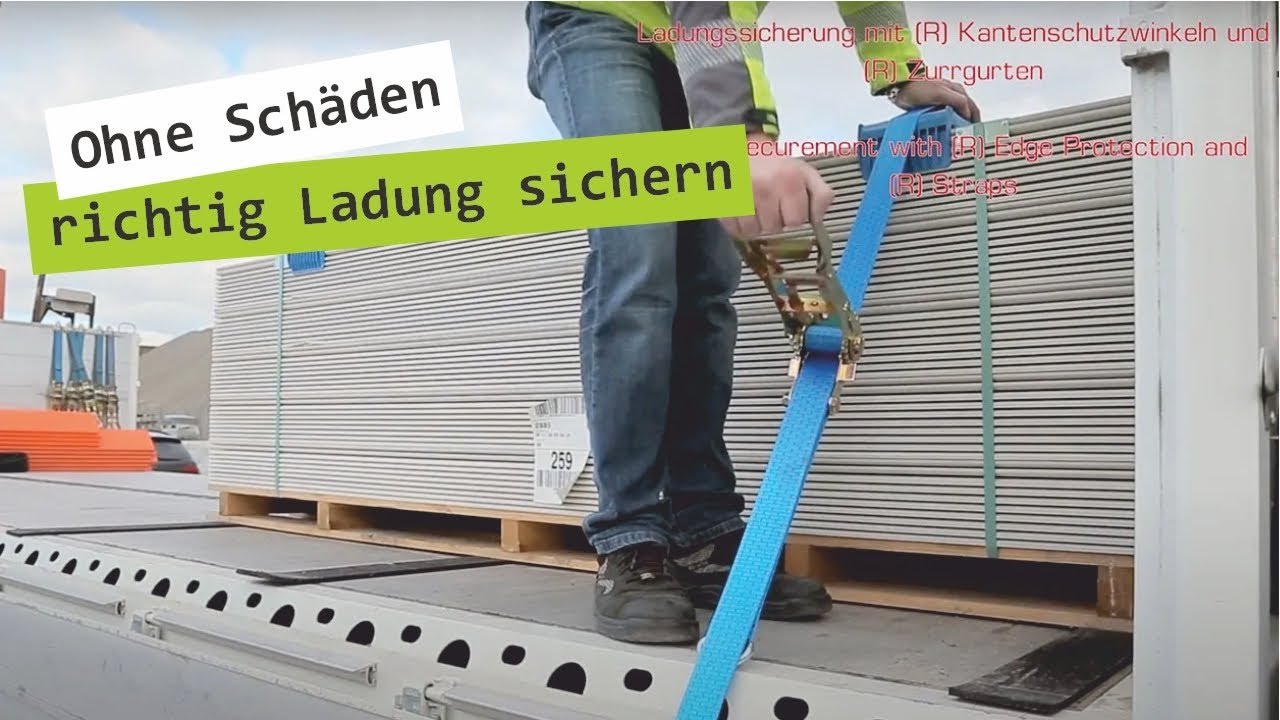

LaSi with lashing straps

Secure protection for sensitive truck goods

Highly sensitive and fragile goods require special load securing equipment. Rothschenk offers a wide range of edge protection angles that distribute the pressure from the edges to larger areas and thus effectively protect the transported goods.

For detailed instructions on how to use these products correctly, take a look at our explanatory video in which the use of Rothschenk plastic angle brackets K 185×60 and lashing straps with pressure ratchet is demonstrated in practice.

- Quick and easy to use

- High-quality materials

- Individual printing on customer request

- Ergonomic options with ERGO long lever available with Ergo long lever.

- Durability and safety: Sturdy belt construction and compliance with EN 12195-2 for abrasion resistance and durability.

- preload force:

-

- Lashing strap with pressure ratchet and pointed hook: STF 300daN

- Lashing strap with ERGO long lever tension ratchet and pointed hook: STF 500daN

- Hand force: SHF 50 daN

- Load capacity in straight pull: 2,500 daN

- Load capacity in strapping: 5,000 daN

- Length (total/fixed end/loose end): 8.0/0.4/7.6 m

- Strip width: 50 mm

- Belt elongation: <5%

- Material:

-

- Webbing: PES (polyethersulfone)

- Fittings: Metal

Lashing straps FAQ

Frequently asked questions

The selection of the correct length and strength of lashing straps depends on the type and weight of the load and the configuration of the transport vehicle. It is important to choose belts that are long enough to securely enclose the load and that have sufficient tensile force to keep the load stable during transportation.

To ensure that you choose the optimum belts for your specific needs, we offer professional advice. Contact us for individual advice and find out more about our security solutions.

Ideally, lashing straps should be checked for damage such as cuts, abrasion or material fatigue before each use.

It is also recommended that the belts are thoroughly inspected regularly, but at least once a month if they are used frequently. This ensures that they can always provide the necessary security. If there are signs of wear or damage, the straps should be replaced immediately to ensure safety during transportation.

Environmental conditions such as weather and temperature can have a significant impact on the properties and performance of lashing straps. Extreme conditions can weaken the material, which is why the selection of lashing straps that are suitable for specific operating conditions is crucial.

The correct use of lashing straps is also essential for road safety, as improperly secured loads can lead to serious accidents and injuries while driving.

Do you still have questions about our lashing straps?

Send us a message

Industriestrasse 5 & 7-10

97239 Aub, Germany

Service hours:

Mon - Thu | 8:00 - 17:00 Fri | 8:00 - 13:00 Pickup/Delivery: Mon- Fri | 7:00 a.m. - 3:00 p.m.