Now 10% off all Ergolash lashing straps save now! Voucher code: ergo10 | Valid until 31.05.2025

Given the occasion, I would like to bring forward a topic that also deals with responsibility. This primarily concerns companies that stow containers or have them stowed. Compared to the old CTU packing guidelines, the CTU Code has developed into a binding set of regulations and the authors have fortunately also oriented themselves to the structure of dangerous goods legislation.

The CTU Code already refers to people involved in the transport chain in the preamble. All those involved should be able to rely on each individual fulfilling their tasks properly and conscientiously.

Chapter 4 of the CTU Code assigns certain responsibilities to the parties involved, which are described in detail as obligations. Even if it refers to persons, the first step always refers to the company and the second to a specific person who must be named by the company.

Chapter 1.4.2 of the ADR lists the main parties involved. In addition, the comment: “ Various parties to whom …. Security obligations can be assigned to one and the same company. The activities and the corresponding security obligations of a participant may also be performed by different companies ” . This clearly shows that the owner/managing director of a company is the person at the top and is responsible to the legislator.

In one of the next blog posts, I will describe the handling, organization and management of responsibility in general.

Chapter 4ff of the CTU Code provides a specific and detailed description of the parties involved and their obligations. The preliminary remark also seems important to me: “Regardless of national legislation or contracts between the parties involved, the following chain of responsibility defines the functional areas of responsibility of the parties involved.” In other words, the person who actually carries out the activity.

The following parties are named:

4.2.1 The CTU operator shall

4.2.2 The consignor shall

4.2.3 The packer should

4.2.4 The shipper/consignor shall

4.2.5 The road haulier shall

4.2.6 The railroad undertaking shall

4.2.7 The operator in intermodal transport should

4.2.8 The carrier shall

4.2.9 The recipient of the CTUs should

4.2.10 The charterers/shippers and operators of empty CTUs

4.2.11 All parties referred to in section 4.2 are required to

4.2.12 All parties involved should

It is important for everyone involved to check who I am. Once this has been clarified, they will find a list of the obligations they have to fulfill in the relevant section. Of course, it is possible that not all obligations apply in a specific case because they may be assumed by a contracted company. However, the party at the beginning of the transport/supply chain who has made promises to the recipient must ensure that the flow of information is guaranteed.

The concrete fulfillment of the obligations must be reflected in the company through the following measures:

– An appropriate organization or organization chart from which the responsibilities and tasks at the various levels can be clearly identified.

– Work instructions and/or checklists that can be used to monitor the fulfilment of obligations with verifiable criteria.

– A control organization that ensures that all verifiable criteria are documented.

– Proof that all persons involved have been trained/educated and/or instructed.

The following statement in the CTU code is therefore interesting:

13.1.5 The management of a facility where CTUs are packed is responsible for ensuring that all persons involved in the packing of cargo into CTUs or in the supervision of this operation are appropriately trained and qualified in accordance with their responsibilities within their organization.

I would like to mention a few points here, because experience has shown that they often go wrong.

Example: Incoming container inspection

It is not uncommon for the prescribed incoming inspection of the container not to be carried out by the “packer”. Neither the CSC sticker is checked for validity nor the container for damage. This can result in the container being taken out of service or an invoice for its repair.

Example: Load securing in a container

When observing the stowage process, it can be seen time and again that the employees start with the most beautiful and pleasant parts of the load and leave the problematic ones for last. Securing the load is then difficult, time-consuming and material-intensive and, as a result, often inadequate. When the container is opened, the first thing the inspection authority sees is the inadequate condition. This can be prevented with a stowage plan that is drawn up before work begins.

Example: Load distribution in the container

Following the example above, the overall center of gravity of the container is also skewed. With the stowage plan, these tasks can also be completed without any problems.

Such a clear and unambiguous allocation of responsibility can only be found in a few sets of regulations.

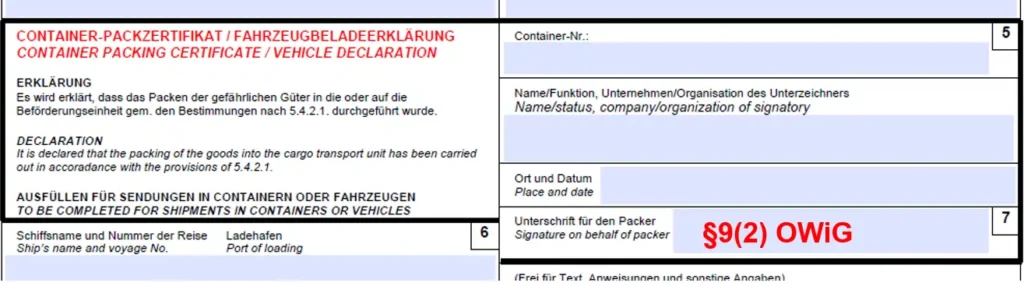

Example container packing certificate

This signature can have far-reaching consequences if damage occurs to the goods, the container or the ship.

This signature field must be signed by the person who has been appointed in writing by the company acting as packer in accordance with: §9(2) OWiG (“2. expressly instructed to carry out tasks on their own responsibility which are incumbent on the owner of the company“).

As a rule, this is not the employee who stows and packs the container. As a general rule, everyone involved must be trained/instructed to take on tasks and activities in accordance with the CTU Code.

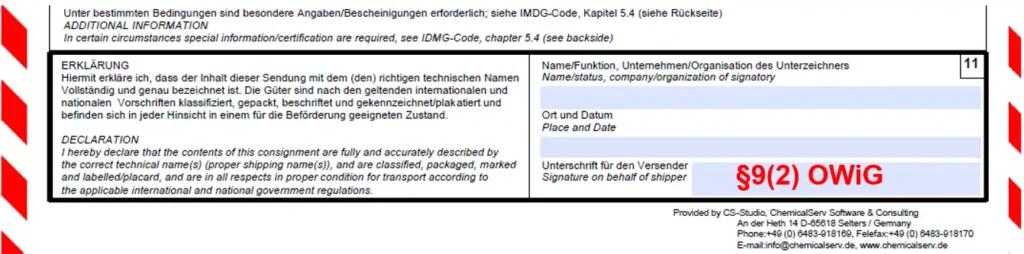

The same applies to this field as mentioned above for the shipper. In addition, the person providing the signature and all other parties involved must be instructed in accordance with IMDG Code Chapter 1.3, as the goods are dangerous goods.

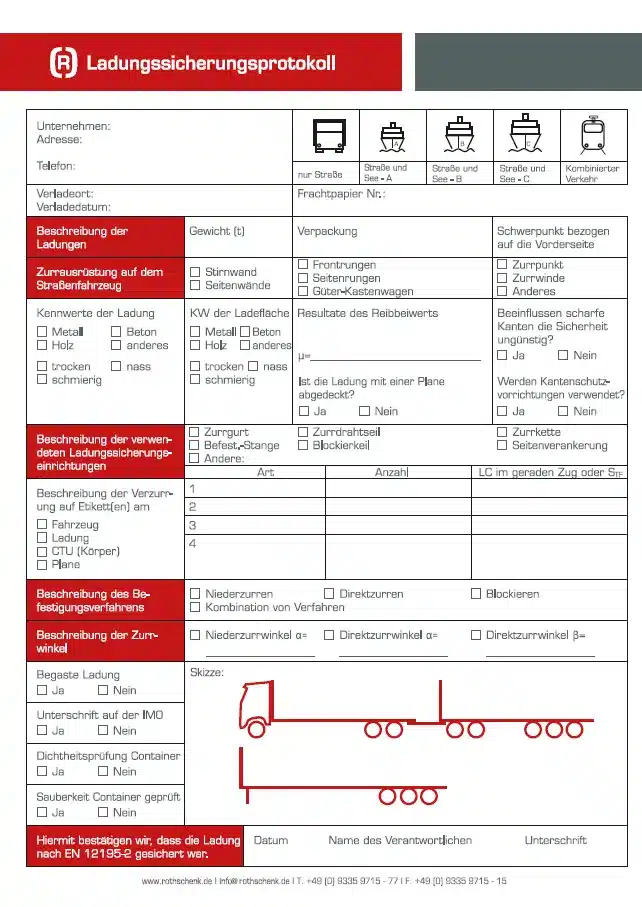

Example documentation

The processes involved in packing a container often take place in such a way that nobody knows exactly what was actually done afterwards. There is a lack of the necessary work instructions, instructions on how it should be done and monitoring. Checklists have proven to be excellent for this. They can be worked through step by step.

This load securing protocol is an example of how the checklist can be designed.

However, it is essential to adapt each template to your own requirements.

Sometimes the template contains items that do not exist at all in your own company.

If these are then ticked off as OK every time, this seems implausible.

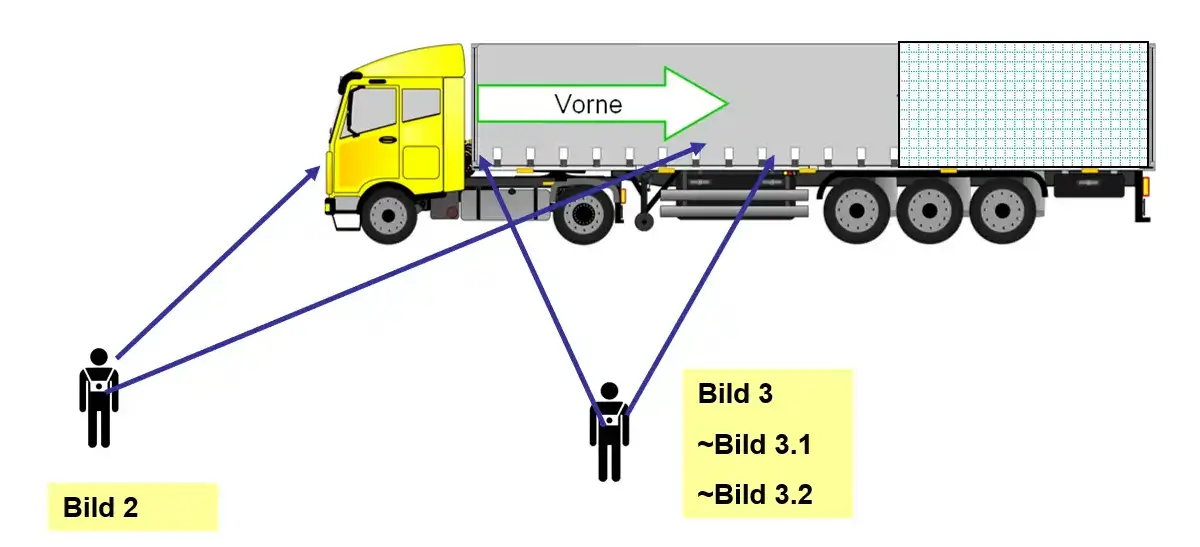

Another good method is to take photos to supplement the checklists. Please remember that they should be properly exposed, in focus and only show what is to be documented. For this purpose, it is useful to have a photo instruction that shows which photos are to be taken so that a uniform, regular and comprehensible record is created.

The instructions should clearly state the position from which the images are to be taken. The minimum scope of the images must also be defined so that the documentation is always of the same standard.

In relation to the millions of containers that are transported, “thank goodness” comparatively little happens. If such a case occurs, it is usually tragic and expensive. If everyone involved takes their duties seriously and fulfills them, most transports will run smoothly.

PS: the checklist described can be downloaded from this link.

Yours, Sigurd Ehringer

<< Previous article

Episode 48: Is it necessary to secure loads at the top of the container?

To the next post >>

Sigurd Ehringer

✔ VDI-zertifizierter Ausbilder für Ladungssicherung ✔ Fachbuch-Autor ✔ 8 Jahre Projektmanager ✔ 12 Jahre bei der Bundeswehr (Kompaniechef) ✔ 20 Jahre Vertriebserfahrung ✔ seit 1996 Berater/Ausbilder in der Logistik ✔ 44 Jahre Ausbilder/Trainer in verschiedenen Bereichen —> In einer Reihe von Fachbeiträgen aus der Praxis, zu Themen rund um den Container und LKW, erhalten Sie Profiwissen aus erster Hand. Wie sichert man Ladung korrekt und was sind die Grundlagen der Ladungssicherung? Erarbeitet und vorgestellt werden sie von Sigurd Ehringer, Inhaber von SE-LogCon.

Rothschenk assortment

Our customer center has only one goal: to turn your problems into solutions. Whether standard stowage cushions, bestsellers or load securing personally tailored to your needs -. we accompany you consistently from A as in field service to Z as in certification. That is our promise to you, as a leader in our industry.

We attach great importance to professional cargo securing. That is why we have our own production, which ensures reliable operation through modern manufacturing technologies and strict quality control. Thus, we offer our customers a comprehensive and high-quality range of services in the field of transport logistics.

DIN ISO 9001:2015, EMAS and Ecovadis are not foreign words to you? Then it's time to work with the best.

You don't take any risks with us - we have been awarded the Platinum Medal on the EcoVadis sustainability rating platform.

As a load securement company, we are proud to have several certifications that validate our sustainability efforts and our commitment to environmental protection and social responsibility. For you as a purchaser, this means that we demand and promote the implementation of high environmental and social standards both within the company and along the supply chain.

>WHITE LINES AND RED LINES

— Product category

For orders over €50

Valid until October 31, 2025

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information