TRUCK dunnage bags

Perfect form fit and

simple axle load distribution

- Robust, durable design

- Flexible application options

- Sustainable upholstery that is 100% recyclable

- Quality Made in Germany

Optimum load securing

TRUCK dunnage bag

The loading situations on the truck are constantly changing, meaning that the load securing equipment required is exposed to high loads in order to provide the necessary securing force. Our dunnage bag are therefore consistently designed as a reusable solution and made of robust material.

Whether it’s our innovative [R] Dually Bag, the double chamber pad or a 3D dunnage bag: what they all have in common is that they are designed for particularly large stowage gaps. If, on the other hand, the goods have a base, i.e. are smaller than the base area of the pallet, our saddlebag is used. The dunnage bag fills the gaps in the stowage so that a form fit is created between the pallets again.

Further information on truck dunnage bags

Truck dunnage bag create the positive fit between the goods and/or body parts of the truck. In this way, you not only fill existing gaps, but also help to take axle load distribution into account when planning the loading.

According to VDI 2700, factors such as permissible front and rear axle load and permissible payload must be taken into account. In order to position the resulting center of gravity of the load ideally above the axles, it is often necessary not to unload the goods completely, but to leave gaps in between. These can fill dunnage bags in a time-saving and form-fitting manner.

- Laminated fabric makes it resistant to mechanical damage

- moisture resistant

- Environmentally friendly, 100% recyclable

- Simple and flexible to use

- Freely accessible valve position

- Fast filling with compatible Rothschenk filling systems

- Individual sizes available

- Outer padding: PP (polypropylene) ribbon fabric, coated

- Inner padding: PE (polyethylene) film

- Valve: SMART, BIG TURBO, SLIM

- Environmental note: Joint disposal of PP and PE, fully recyclable, unproblematic when incinerated

Rothschenk's truck dunnage bag

All-in-one LaSi solution: Versatile, robust and sustainable!

Rothschenk offers a range of truck dunnage bags that have been specially developed for demanding use in constantly changing loading situations. These returnable solutions include innovative designs such as the [R] Dually Bag, double chamber and 3Ddunnage bag, which are ideal for large stowage gaps. In addition, the saddlebag provides a solution for goods smaller than their pallets by filling gaps and ensuring a tight fit. The cushions are made of robust, laminated fabric, are moisture-resistant, environmentally friendly and known for their ease of use. Specially developed truck clipboard dunnage bag fill empty spaces along the loading area and prevent the goods from tipping, supported by simple filling and color coding for correct attachment. All cushions are TÜV Rheinland certified, reusable and can be adapted to individual requirements.

The special solution

TRUCK truck clipboard dunnage bag

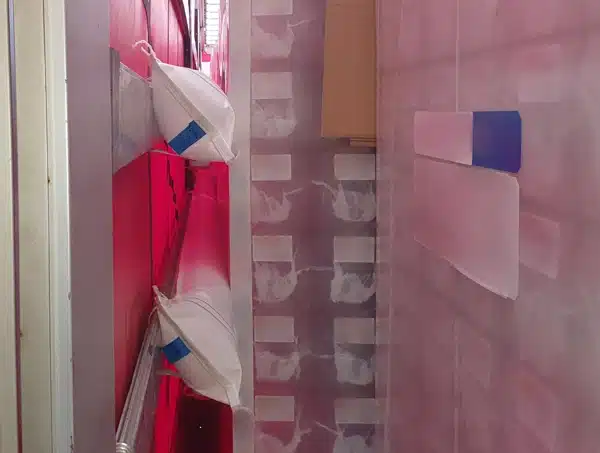

[R] truck clipboard dunnage bag were developed to fill the empty spaces between the side slats of a truck and the goods. The aim is to create a positive fit and prevent the goods from tipping over.

They are attached over the entire length of the loading area using elastic bands. Loading then begins as usual. Once loading is complete, the truck clipboard dunnage bag are filled, e.g. with a mobile battery blower or compressed air.

To ensure that the valves are always accessible from the rear, both sides are color-coded for use on the right or left side.

Further information on truck bows

If there are small gaps in the load when the goods are high and at risk of tipping, it was previously difficult to create a tight fit towards the tarpaulin.

On a truck with an XL body, the side wall has a load capacity of up to 40%. This results from the special design with lateral stop bar for the pallets and the construction of the insert slats and tarpaulin.

The truck clipboard dunnage bag makes use of this special feature, as it is attached to the slats and fills the gap between the goods and the slats with a positive fit. In combination with anti-slip mats and an XL superstructure, this eliminates the need for the majority of conventional load securing methods such as lashing straps.

- TÜV Rheinland certified

- Positive locking achievable over the entire length of the vehicle

- Width 270 mm flexibly adjustable

- Simple operation using mobile battery blower or compressed air

- reusable

- Color coding from right/left

- recyclable

- Outer padding: PP (polypropylene) ribbon fabric, coated

- Inner padding: PE (polyethylene) film

- Valve: SMART

- Environmental note: Joint disposal of PP and PE, fully recyclable, unproblematic when incinerated

(R) truck clipboard dunnage bag Load securing

Innovative solution for your truck transport

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationCreating a tight fit to secure loads in trucks is essential, especially when bridging gaps such as between goods and bows. Our new [R] truck clipboard dunnage bag, demonstrated in our application video, is specially designed to cover the entire length of a truck (13.6 m).

Before loading, the cushion is simply attached with a flexible strap and quick-release fastener and inflated after the loading process. It is also TÜV Rheinland certified, which confirms its quality and safety. Watch the video to see the application in action.

The [R] truck clipboard dunnage bag system from Rothschenk offers special advantages that set it apart from other load securing systems. Thanks to its adjustable width and unique design, which enables complete positive locking along the length of the vehicle, it ensures optimum securing of the load. It is also TÜV Rheinland certified, which underlines its reliability and quality. Easy handling using mobile battery blower or compressed air and reusability make it a sustainable and efficient solution in modern logistics.

They also make an effective contribution to sustainability thanks to their recyclable materials and robust design, which also means a cost-effective long-term solution for transport companies.

Once loading is complete, the truck clipboard dunnage bag are filled either with a mobile battery blower or with compressed air. This makes handling simple and efficient and enables quick adaptation to the loading situation.

For this purpose, Rothschenk offers a range of practical accessories for dunnage bag, which you can conveniently order in our (R) online store.

- Outer padding: PP (polypropylene) ribbon fabric, coated

- Inner padding: PE (polyethylene) film

- Valve: SMART

dunnage bag Products

Our product recommendations for you

- Select options This product has multiple variants. The options may be chosen on the product page

- Select options This product has multiple variants. The options may be chosen on the product page

- Select options This product has multiple variants. The options may be chosen on the product page

- Select options This product has multiple variants. The options may be chosen on the product page

- Select options This product has multiple variants. The options may be chosen on the product page

- Select options This product has multiple variants. The options may be chosen on the product page

- Select options This product has multiple variants. The options may be chosen on the product page

- Select options This product has multiple variants. The options may be chosen on the product page

- Select options This product has multiple variants. The options may be chosen on the product page

- Select options This product has multiple variants. The options may be chosen on the product page

- Select options This product has multiple variants. The options may be chosen on the product page

- Select options This product has multiple variants. The options may be chosen on the product page

dunnage bag FAQ

Frequently asked questions

A dunnage bag consists of an inlay made of PE (polyethylene) film which acts as an air chamber. This inner layer is surrounded by a PP (polypropylene) fabric to ensure protection against abrasion and weathering.

In contrast to dunnage bags where the outer layer is made of paper, protection against moisture, e.g. from splashing water or container rain, is guaranteed. In addition, PP/PE dunnage bag can be used between the goods and the container wall. The combination of two plastics also makes disposal more environmentally friendly than with a paper-wrapped dunnage bag with a PE inlay.

Two options have proven successful for filling dunnage bags with air.

If a stationary compressed air system is available, the dunnage bag can be filled using a compressed air gun and a suitable adapter for the installed valve. The advantage is a high filling speed due to the high air volumes available.

When using compressed air, however, precautionary measures must also be taken to avoid overfilling and bursting of the dunnage bag. For example, it is advisable to use a compressed air gun with an automatic blow-off function if the pressure is too high. In addition, the values specified by the manufacturer, such as working pressure and maximum filling pressure, should be observed.

Battery-powered filling devices are a relatively new alternative. Due to their design, there is no compressed air supply line, which reduces the risk of accidents caused by hoses lying around.

Furthermore, it is not so easy to overfill the dunnage bags as the power of the battery-powered devices generally allows somewhat lower pressures. However, these are generally sufficient for the required securing forces in load securing.

The correct size of a stowage cushion depends on the stowage gap to be filled. The aim is to achieve maximum form fit between the adjacent goods or container wall or truck. The dunnage bag should be selected in such a way that it prevents the goods from slipping and at the same time does not damage the goods themselves. To achieve this, the contact surface of the pad with the adjacent surfaces must be as large as possible.

To ensure this, it may be necessary to use different types of construction. In addition to the use of a classic dunnage bag, there are also cubic, 3D dunnage bags or special solutions such as a dually bag consisting of two firmly sewn dunnage bags. The different load carriers such as trucks or containers and their shipping routes such as sea, rail or road also place different demands on the load securing equipment. There is therefore a high variance in the types of dunnage bags available.

The higher the load weight to be secured, the greater the load capacity of a dunnage bag must be. In order to classify performance, the AAR (Association of American Railroads) guidelines define various level classifications. This independently certified load securing equipment guarantees the buyer the quality required for his loading.

The correct selection of the appropriate stowage cushion is regulated in the CTU code.

It describes both how large a dunnage bag must be dimensioned in order to secure a load weight at defined accelerations and friction coefficients.

Another point defined in the CTU code is the load forces that a dunnage bag with known dimensions can absorb.

To select the right dunnage bag, the user must know both criteria and make the selection using predefined formulas.

Practical experience has shown that a pad which is dimensioned according to the load can generally absorb considerably more load force than is actually required. However, this does not release the user from the possibility of consulting the manufacturer of dunnage bags and requesting specific handling data.

Do you have any questions about dunnage bag?

Send us a message

Industriestrasse 5 & 7-10

97239 Aub, Germany

Service hours:

Mon - Thu | 8:00 am - 5:00 pm Fri | 8:00 am - 1:00 pm Collection/delivery: Mon - Fri | 7:00 am - 3:00 pm

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information