Now 10% off all Ergolash lashing straps save now! Voucher code: ergo10 | Valid until 31.05.2025

When loading a truck from the rear, it is often safe to drive onto the loading area with the forklift. Very few people think about whether this is even permissible and whether the floor can withstand the load.

The technical regulation for the load capacity of a truck body can be found in EN-12642 Code XL.

Load securing on road vehicles – “Bodies on commercial vehicles – Minimum requirements; German version EN12642:2016” is the title.

Unfortunately, this standard makes no reference to the load-bearing capacity of the floor, only to the superstructure.

It is necessary to read another standard, namely DIN EN 283 “Swap bodies – Testing“.

This specifies in detail how the soils are to be tested. As a rule, this standard is not accessible to the shipper who is entrusted with loading a truck. He must therefore adhere to the information provided by the trailer manufacturer or specified by the employers’ liability insurance association as a boundary condition.

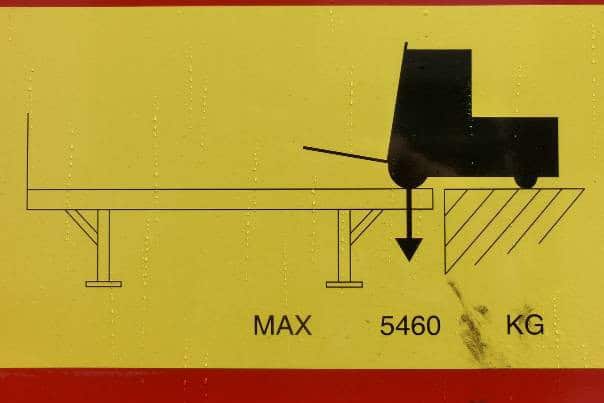

The manufacturers use the following markings, for example, which are usually located on the left or right of the rear portal or on the inside of the door.

Care must therefore be taken to ensure that the load + truck do not have a higher axle load. According to the TIS-GDV, forklifts with max. 2.5 tons of lifting capacity.

Of course, driving on a loading area also involves risks from a “work safety” perspective. Especially when the semi-trailer is uncoupled from the tractor unit or the swap body is set down. In some cases, manufacturers make concrete specifications, but in general the shipper must take this into account, even if no instructions are given.

If the axle load is too high when driving onto the empty trailer, it can tip over and the truck falls into the resulting gap. Here

the manufacturer has limited the axle load to 3,000 kg.

Care must also be taken to ensure that the axles of the trailer are blocked with wedges to prevent it from rolling away.

The driver must place the chocks and the loader must check them.

Of course, there is also the critical situation when the first pallets are placed against the front wall with the forklift truck. It is then located in front of the trailer’s support legs.

If the axle load is more than 5,460 kg, the trailer can tip forwards.

The manufacturer Kögel, for example, uses the marking to indicate that the empty trailer may only be driven on if it is supported at the front and rear.

The front support must be positioned in front of the kingpin. The attached parking supports are not sufficient.

Here is an example of what such a support might look like. Source: https://www.europieces.lu/de/verladetechnik/sicherheitsstuetzen-undsicherheitsboecke-fuer-lkwauflieger/sicherheitsstuetzen-fuer

BGV D29 “Vehicles”, with the new title “DGUV 70 Vehicles”, states in § 37 “Loading and unloading” paragraph: (2) When loading and unloading vehicles, it must be ensured that they cannot roll away, tip over or overturn.

This is the clear requirement of the employers’ liability insurance association for accident prevention. It is therefore advisable to organize the processes in such a way that the regulations are complied with. This includes collecting the necessary information before loading to ensure safe loading and unloading.

Every company should have a clear work instruction/checklist for this situation to ensure a regulated process.

Yours, Sigurd Ehringer

<< Previous article

Episode 21: dunnage bag Load securing – Part 2

Next post >>

Episode 23: Positive locking on trucks

Sigurd Ehringer

✔ VDI-zertifizierter Ausbilder für Ladungssicherung ✔ Fachbuch-Autor ✔ 8 Jahre Projektmanager ✔ 12 Jahre bei der Bundeswehr (Kompaniechef) ✔ 20 Jahre Vertriebserfahrung ✔ seit 1996 Berater/Ausbilder in der Logistik ✔ 44 Jahre Ausbilder/Trainer in verschiedenen Bereichen —> In einer Reihe von Fachbeiträgen aus der Praxis, zu Themen rund um den Container und LKW, erhalten Sie Profiwissen aus erster Hand. Wie sichert man Ladung korrekt und was sind die Grundlagen der Ladungssicherung? Erarbeitet und vorgestellt werden sie von Sigurd Ehringer, Inhaber von SE-LogCon.

Rothschenk assortment

Our customer center has only one goal: to turn your problems into solutions. Whether standard stowage cushions, bestsellers or load securing personally tailored to your needs -. we accompany you consistently from A as in field service to Z as in certification. That is our promise to you, as a leader in our industry.

We attach great importance to professional cargo securing. That is why we have our own production, which ensures reliable operation through modern manufacturing technologies and strict quality control. Thus, we offer our customers a comprehensive and high-quality range of services in the field of transport logistics.

DIN ISO 9001:2015, EMAS and Ecovadis are not foreign words to you? Then it's time to work with the best.

You don't take any risks with us - we have been awarded the Platinum Medal on the EcoVadis sustainability rating platform.

As a load securement company, we are proud to have several certifications that validate our sustainability efforts and our commitment to environmental protection and social responsibility. For you as a purchaser, this means that we demand and promote the implementation of high environmental and social standards both within the company and along the supply chain.

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information