Now 10% off all Ergolash lashing straps save now! Voucher code: ergo10 | Valid until 31.05.2025

As containers are one of the most common means of transportation, you see many of them on the road, usually from behind. There is a lot of information on the rear doors that is very important for those who have to load containers. Therefore, I would like to explain the labeling and its meaning in this episode.

In the upper third on the left-hand side is the logo of the container owner, Fa. Hanjin, and their website for more information. However, this information is not mandatory. The right-hand side is much more important, as it contains information that must be included in the container identification. This 10-digit letter/number code must be affixed at this point and on all sides.

The complete identification from the picture is: HJC U 192271 3

First of all, there is the owner code “HJCU“. The letters HJC stand for the company. Hanjin, while the letter “U” (the product group code) stands for Unit and therefore appears in all owner abbreviations in the container area.

The 6-digit registration number “192 271” alone is not sufficient for unambiguous identification. It always consists of 6 digits and missing digits are filled in with zeros by the owner. The slightly spaced 3 is the check digit. It is used to check the accuracy and plausibility of the information. Data processing systems have an algorithm that converts the information “HJC U 192271″ and obtains the check digit 3 as the result. If the result is not “3”, then the specification/sequence must be incorrect. It is therefore advisable to adopt the registration in the spelling “HJCU 192 271 [3]”. This is important in order to avoid sources of error, especially in the case of handwritten copies.

In addition to the identification number, the type designation of the container is also located in this area. In the example, the type designation is 45G1 . However, some refer to this type as a 45″ container. That is wrong.

The type designations are regulated in ISO 6346 and consist of 3 elements. The first two numbers stand for the length and height of the container. The letter/number combination for the intended use.

The designation G1 stands for a container with passive ventilation. However, these ventilation openings, just below the upper side member, are primarily used for pressure equalization.

The internal temperature of the container can rise sharply when exposed to sunlight, causing the air to expand and inflate the container due to overpressure. This is prevented by the pressure equalization openings. Their functionality must be checked during the initial check.

Important loading information is provided in the middle third of the right-hand container door. The weight is given in American pounds (1LB/LBS=0.454 kg) and kilograms(KG).

The maximum weight(MAXGROSS) of the container is 32,500 kg or 71,650 LB.

The tare weight(TARE) is 3,930 kg, or 8,660 LB. This information must be used when determining the verified gross weight(VGM). Details on the verified gross weight(VGM) will be described in one of the next episodes.

This includes information on the payload(PAYLOAD) and volume(CUBE). The container is designed for a maximum payload of 28,570 kg and has a volume(CUM) of 76.4m3. When loading the container, however, it must be taken into account that the total weight of the transport unit may not exceed 40,000 kg (40 t) or 44,000 kg (44 t) for road transport. This means that, depending on the unladen weight of the transport unit (tractor unit + chassis + tare of the container), far fewer kilograms may be loaded than the specification on the container door.

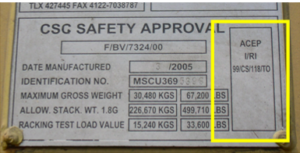

The so-called CSC badge is located in the lower third of the left or sometimes also the right container door. This sticker must be present for transportation by sea. This is therefore the most important point in the incoming goods check by the shipper/packer. If this sticker is missing, the container may not be loaded.

It indicates whether the container has been inspected by the owner in accordance with CSC(Convetion for Save Containers) and whether it is suitable and approved for sea transportation. The date of commissioning(DATE MANUFACTURED) is indicated on this sticker as 7/2006.

The first test cycle is 5 years, i.e. 7/2011. Each additional test cycle is reduced to a maximum of 30 months (2 ½ years). The next test date must therefore be “1/2014”. But it must definitely be after the expected end of the journey. If this is not the case, the container must not be loaded.

This CSC examination can be overlaid by the so-called ACEP rule(Approved Continuous Examination Program). This means that the owner ensures that the inspection interval is generally 30 months. Its registration number for this program is expressed by the letter/number code I/RI 99/CS/118/TO.

It may also be different for another registration authority. For example, for Hapag-Lloyd ACEP-D-HH-3, if the container has one of these ACEP markings, an inspection date is no longer required.

The container doors also have other technical details that must be observed or checked during the incoming goods inspection. Specifically focusing on CSC badge and ACEP verification. And that will be the subject of the next episode.

Yours, Sigurd Ehringer

Sigurd Ehringer

✔ VDI-zertifizierter Ausbilder für Ladungssicherung ✔ Fachbuch-Autor ✔ 8 Jahre Projektmanager ✔ 12 Jahre bei der Bundeswehr (Kompaniechef) ✔ 20 Jahre Vertriebserfahrung ✔ seit 1996 Berater/Ausbilder in der Logistik ✔ 44 Jahre Ausbilder/Trainer in verschiedenen Bereichen —> In einer Reihe von Fachbeiträgen aus der Praxis, zu Themen rund um den Container und LKW, erhalten Sie Profiwissen aus erster Hand. Wie sichert man Ladung korrekt und was sind die Grundlagen der Ladungssicherung? Erarbeitet und vorgestellt werden sie von Sigurd Ehringer, Inhaber von SE-LogCon.

Rothschenk assortment

Our customer center has only one goal: to turn your problems into solutions. Whether standard stowage cushions, bestsellers or load securing personally tailored to your needs -. we accompany you consistently from A as in field service to Z as in certification. That is our promise to you, as a leader in our industry.

We attach great importance to professional cargo securing. That is why we have our own production, which ensures reliable operation through modern manufacturing technologies and strict quality control. Thus, we offer our customers a comprehensive and high-quality range of services in the field of transport logistics.

DIN ISO 9001:2015, EMAS and Ecovadis are not foreign words to you? Then it's time to work with the best.

You don't take any risks with us - we have been awarded the Platinum Medal on the EcoVadis sustainability rating platform.

As a load securement company, we are proud to have several certifications that validate our sustainability efforts and our commitment to environmental protection and social responsibility. For you as a purchaser, this means that we demand and promote the implementation of high environmental and social standards both within the company and along the supply chain.

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information