Now 10% off all Ergolash lashing straps save now! Voucher code: ergo10 | Valid until 31.05.2025

After describing the technical boundary conditions for anti-slip mats based on VDI-2700 Sheet 15 in the previous blog, the following article deals with their practical application.

The guideline does not mention this and there are also few book writers who deal with this matter from a practitioner’s perspective.

I’ll try to put my experience into concrete examples. In principle, it is never wrong to work with anti-slip mats (ARM) when securing loads. In most cases, they bring more advantages than disadvantages.

People often ask how thick the mats should be. The wise answer is that it depends. In purely mathematical and theoretical physical terms, the thickness of the mats is irrelevant. But it is practical.

The ARMs must ensure that the two surfaces, namely the loading surface and the load parts/load carriers that touch the loading surface, are separated from each other via the mats. The technical term for this is decoupling .

Take, for example, a uniformly packed Euro pallet weighing 1,000 kg.

The costs are always based on weight, even if a price/piece is stated in the offer. But the price is not the decisive factor, it is the safe handling and the safe result.

There are enough accidents where the truck driver corrects the ARM again and the forklift driver puts the pallet on his fingers because he didn’t see him.

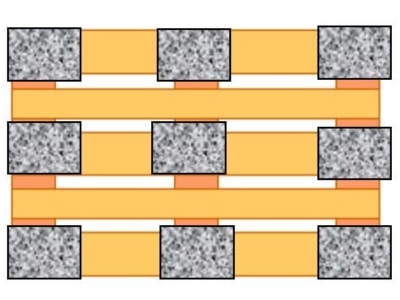

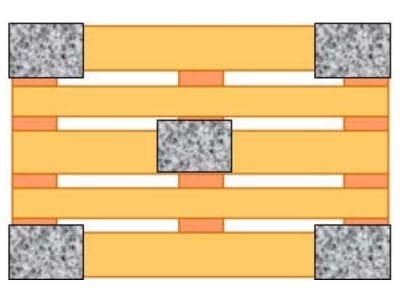

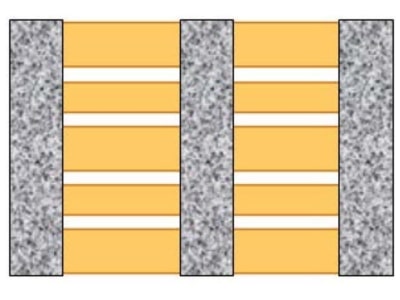

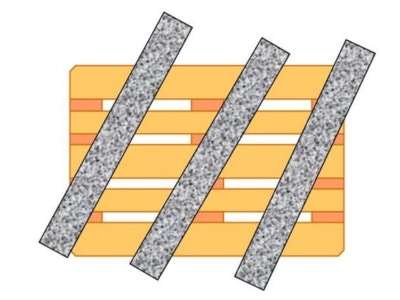

There are various ways in which anti-slip mats (ARM) can be laid. Here are a few examples:

The most complex method is shown on the right. Here, 9 ARM pads must be placed precisely in order to decouple the load from the loading surface.

It is particularly necessary if the ARMs are very thin (less than 4 mm).

This scheme is also required if the ARMs are thin. Another disadvantage is that they cannot be easily corrected.

It is usually not possible to push them because they are not stiff enough. They must therefore be lifted and repositioned.

This scheme can be used if the mats are at least 8 mm thick and the pallet is evenly packed and loaded.

This scheme is also possible if the ARMs are at least 8 mm thick, 200 mm wide and 800 mm long. Here, too, the positioning must be reasonably precise.

This is the elegant solution if the ARMs are at least 8 mm thick, 200 mm wide and 1200 mm long. The big advantage is that the ARMs do not have to be positioned precisely because the pallet always has enough contact surface to ensure that it is decoupled from the loading area.

With this scheme, the next pallet can also be placed on the protruding strips. Corrections are not necessary with a little experience.

The aim must always be to decouple the loading surface and the load carrier.

The picture on the right shows a clear gap between the load carrier and the loading area.

This picture also shows that thicker ARMs produce a better result than thin ones.

The dimensionally stable plastic pallet is decoupled from the loading area with two ARM strips.

Inappropriate installation of the ARMs often results in their effectiveness being greatly reduced or non-existent.

Those involved believe they have a sense of security that does not actually exist.

One of the most common causes is the loading area not being “swept clean”. The ARMs are placed on the more or less existing dirt on the loading area.

This results in a layer between the ARM and the loading surface, which partially prevents the interlocking and thus the mini-form closure.

The coefficient of friction is therefore no longer μ=0.6, but less. No one involved knows how much less, but a value of 0.6 is assumed.

The following examples show other situations that reduce the effect of the ARM:

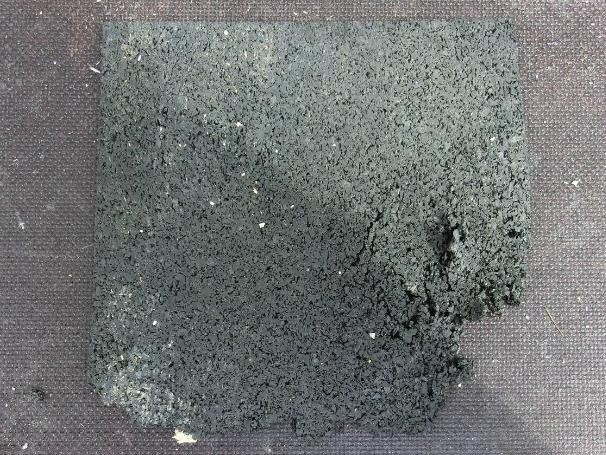

Anti-slip mats that have long since been discarded are still used.

Under load, the ARM must not deform by more than 30% of its thickness. This specification is far exceeded in the picture.

The result is cut-outs like the one in this picture. The base of the loading frame therefore stands on the loading surface without increased friction. The effect is zero.

Another example of the same situation. The problem can be solved with various measures:

Care should also be taken when using ARMs that are not made of rubber granules. When new, they have a very high coefficient of friction. Some manufacturers specify a value of μ=0.8. However, they are very susceptible to dirt and dust. They should therefore only be placed immediately before setting down the load.

After one or more uses, some of these ARMs look like the picture on the right. The anti-slip coating dissolves and the effect or the high coefficient of friction is no longer given.

If ARMs are used, the load must always be additionally secured by lashing down. The reason for this is the vertical acceleration that occurs when driving over uneven road surfaces, potholes, kerbs, bumps, tarred edges, etc. They reduce the normal force with which the load presses against the loading surface, thereby reducing the coefficient of friction and thus also the frictional force.

Loads with low tipping stability immediately start to tip when ARMs are used. Without ARM, such a load would first slide and then tip over. This tilting is also prevented by lashing down. Here is an example:

The actual, perceived or estimated coefficient of friction plays a major role in inspections by the authorities. When calculating the safety measures, it can make a considerable difference whether a value of 0.6 or 0.5 is used. The result may be that the load is deemed to have been properly secured or a fine may be imposed because it was carried out incorrectly.

Everyone involved should therefore address the issue and ensure that the coefficient of friction is always as high as possible.

Measures for this include

Yours, Sigurd Ehringer

<< To the previous post

Episode 38: How does an anti-slip mat work? – Part 1: The principle of action

Sigurd Ehringer

✔ VDI-zertifizierter Ausbilder für Ladungssicherung ✔ Fachbuch-Autor ✔ 8 Jahre Projektmanager ✔ 12 Jahre bei der Bundeswehr (Kompaniechef) ✔ 20 Jahre Vertriebserfahrung ✔ seit 1996 Berater/Ausbilder in der Logistik ✔ 44 Jahre Ausbilder/Trainer in verschiedenen Bereichen —> In einer Reihe von Fachbeiträgen aus der Praxis, zu Themen rund um den Container und LKW, erhalten Sie Profiwissen aus erster Hand. Wie sichert man Ladung korrekt und was sind die Grundlagen der Ladungssicherung? Erarbeitet und vorgestellt werden sie von Sigurd Ehringer, Inhaber von SE-LogCon.

Rothschenk assortment

Our customer center has only one goal: to turn your problems into solutions. Whether standard stowage cushions, bestsellers or load securing personally tailored to your needs -. we accompany you consistently from A as in field service to Z as in certification. That is our promise to you, as a leader in our industry.

We attach great importance to professional cargo securing. That is why we have our own production, which ensures reliable operation through modern manufacturing technologies and strict quality control. Thus, we offer our customers a comprehensive and high-quality range of services in the field of transport logistics.

DIN ISO 9001:2015, EMAS and Ecovadis are not foreign words to you? Then it's time to work with the best.

You don't take any risks with us - we have been awarded the Platinum Medal on the EcoVadis sustainability rating platform.

As a load securement company, we are proud to have several certifications that validate our sustainability efforts and our commitment to environmental protection and social responsibility. For you as a purchaser, this means that we demand and promote the implementation of high environmental and social standards both within the company and along the supply chain.

G&H GmbH Rothschenk

Industriestrasse 5 & 7-10

97239 Aub

Phone: +49 9335 97 15 – 79

Fax: +49 9335 97 15 – 15

E-mail: info@rothschenk.de

Collection/delivery

Mon – Fri: 8:00 – 15:00

Office hours

Mon – Thu: 8:00 – 17:00

Fri: 8:00 – 13:00

G&H GmbH Rothschenk

Industriestrasse 5 & 7-10

97239 Aub

Phone: +49 9335 97 15 – 0

Fax: +49 9335 97 15 – 15

E-mail: info@rothschenk.de

Collection/delivery

Mon – Fri: 8:00 – 15:00

Office hours

Mon – Thu: 8:00 – 17:00

Fri: 8:00 – 13:00

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information