Now 10% off all Ergolash lashing straps save now! Voucher code: ergo10 | Valid until 31.05.2025

As announced in episode 52, I want to go even deeper into the practice, point out mistakes that are often made and present possible solutions.

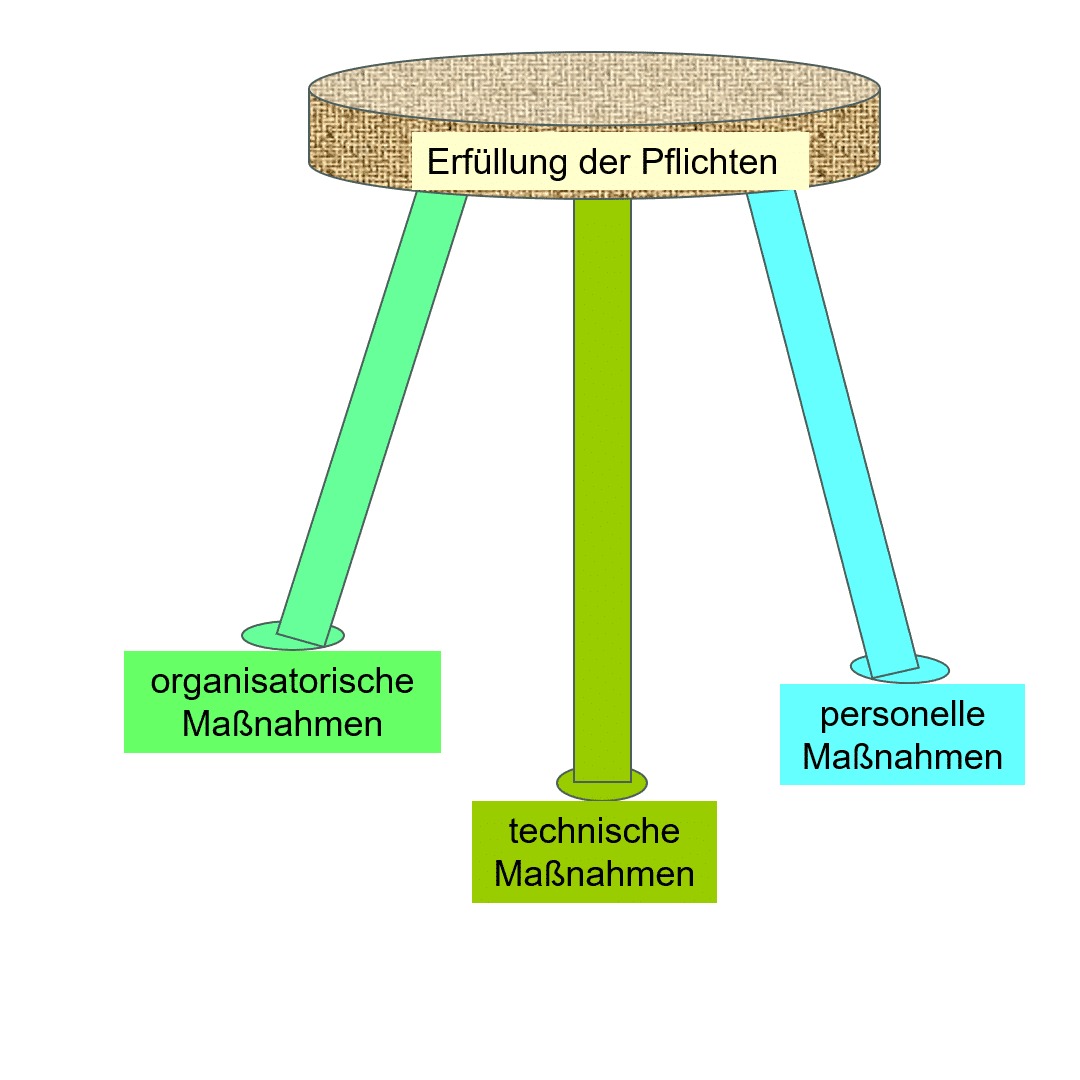

I am again guided by the three pillars for the fulfillment of duties.

The adjacent technical measures can be detailed as follows.

| 1. product requirements 2. expected transport loads 3. Vehicle requirements 4. Load securing equipment 5. Securing methods 6. Loading and unloading equipment |

Based on the basic idea that every product usually goes through a transportation phase to the user/recipient, it would be good to know what loads it can withstand. On the basis of this knowledge, it is then possible to determine the measures and effort required for packaging.

A product that is sensitive to shocks or vibrations must be packaged differently to a machine or system. The choice of means of transport and securing measures can then also depend on this.

In this context, an important VDI guideline should be mentioned, VDI-2700 Sheet 5 “Load securing on road vehicles – Quality management systems”.

The title does not immediately reveal the usable content. It describes the gray area between the client and the carrier/forwarder by breaking down the transport process into thin slices and describing the resulting measures in general terms.

The content of my article is based on this and underpins the whole thing with practical experience. Every logistics manager should be familiar with this guideline and implement its requirements in a company-specific manner.

From the moment a customer orders goods/products, the delivery/recipient location is usually also known. This also makes it possible to determine the expected transportation costs.

The CTU Code 2014 contains a tabular overview of the expected transport loads. This should form the basis for considerations.

A delivery from Germany to America inevitably involves air or sea transport, the pre- and post-carriage always involves road transport and parts of it may also be transported by rail. This means that the considerations are already based on four different transportation loads.

The measures to be taken, e.g. packaging, must be based on the highest transportation load.

If these considerations are neglected, it is only a matter of time before problems and/or transport damage occur. Even at this early stage, consideration should be given to the type of securing method so that the product can be fitted with the necessary attachment points if necessary.

When requesting transportation, decisive measures are omitted. In most cases, you can rely on the vehicle tires being round. But whether they also comply with road traffic regulations is already a risk.

When transporting hazardous goods, the loading company is obliged to check the vehicle for roadworthiness, among other things, which also includes “inspecting” the tires. It is therefore not a TÜV inspection.

Depending on the product to be loaded, the vehicle type, e.g. box body or tarpaulin body, should be specified. If securing with lashing straps is required, it may make sense to request a perforated strip, as this is not standard equipment according to EN-12642. Each strap can then be secured in the optimum position. If crane loading is planned, a reference to a “functional” sliding roof should not be omitted.

The type of collateral should also be determined. The statement “sufficient means of security must be provided” alone contains a number of risks. It has proven to be expedient to specify the securing means, as well as their properties and number.

For example: 10 tension belts with long lever tension ratchets, STF=500daN, LC=2,000daN and two edge protectors per belt.

The note that the belts must not be discarded should not be omitted. It should also be noted that additional expenses due to missing or incorrect securing equipment will be borne by the carrier.

If anti-slip mats are required, reference to the quality requirement in accordance with VDI-2700 Sheet 15 “Anti-slip materials” is definitely appropriate.

The more detailed the vehicle and equipment specification is, the fewer surprises there are and the less they have to deal with because the rules of the game are clear.

The choice of securing method involves a risk that should not be underestimated if it is left to the truck driver.

The assumption that the driver is the specialist is not confirmed by practice. The loading company should have its thumb on the entire process. The most frequently used securing method is lashing down. It is just as often used incorrectly or is inappropriate and inefficient.

Depending on the value of the goods, there should be clear loading instructions that reflect the calculated securing method. The “head of loading” is responsible for this and, in case of doubt, this is the managing director if he has not appointed anyone else. This makes the loading employee’s work easier and the instructions can also serve as a loading log.

The loading and unloading facilities should be clarified so that the recipient can adjust to them.

Not every recipient has a 10-ton forklift with a long fork, for example, which often means that pallets are not placed on anti-slip mats because this makes pushing and pulling difficult.

If crane unloading is necessary, the addition of lifting gear should be considered, especially for machines and systems.

The “technical measures” pillar takes up a lot of space in the VDI guideline and is essential for smooth transportation. The more precisely the processes are planned and the better those involved know their tasks, the lower the risk of things going wrong.

My aim here is also to initiate a thought process. Experience has shown that defects, transport damage or the causes of hearing forms by the inspection bodies can be located precisely in this area.

As the saying goes, “it’s not enough to have the desire to catch fish, you also have to bring the net”.

With this in mind, stay tuned, there will be another episode.

Yours, Sigurd Ehringer

Previous article >>

Episode 52: Who is responsible in companies – mistakes to avoid

To the next post >>

Sigurd Ehringer

✔ VDI-zertifizierter Ausbilder für Ladungssicherung ✔ Fachbuch-Autor ✔ 8 Jahre Projektmanager ✔ 12 Jahre bei der Bundeswehr (Kompaniechef) ✔ 20 Jahre Vertriebserfahrung ✔ seit 1996 Berater/Ausbilder in der Logistik ✔ 44 Jahre Ausbilder/Trainer in verschiedenen Bereichen —> In einer Reihe von Fachbeiträgen aus der Praxis, zu Themen rund um den Container und LKW, erhalten Sie Profiwissen aus erster Hand. Wie sichert man Ladung korrekt und was sind die Grundlagen der Ladungssicherung? Erarbeitet und vorgestellt werden sie von Sigurd Ehringer, Inhaber von SE-LogCon.

Rothschenk assortment

Our customer center has only one goal: to turn your problems into solutions. Whether standard stowage cushions, bestsellers or load securing personally tailored to your needs -. we accompany you consistently from A as in field service to Z as in certification. That is our promise to you, as a leader in our industry.

We attach great importance to professional cargo securing. That is why we have our own production, which ensures reliable operation through modern manufacturing technologies and strict quality control. Thus, we offer our customers a comprehensive and high-quality range of services in the field of transport logistics.

DIN ISO 9001:2015, EMAS and Ecovadis are not foreign words to you? Then it's time to work with the best.

You don't take any risks with us - we have been awarded the Platinum Medal on the EcoVadis sustainability rating platform.

As a load securement company, we are proud to have several certifications that validate our sustainability efforts and our commitment to environmental protection and social responsibility. For you as a purchaser, this means that we demand and promote the implementation of high environmental and social standards both within the company and along the supply chain.

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information