Episode 20: Dunnage bag load securement - Part 1

Cargo must be secured in the container.

The question is not "whether to secure", but "how to secure a load". Even experts do not always agree on the "how". Some say that "nothing has ever happened before" and others that "for God's sake, it can't work like that".

One of many securing methods is the use of dunnage bags. Some people are familiar with these airbags, which fill the empty spaces in parcels and packages and thus prevent the contents from moving. The principle behind this is the same as in the container.

About the author:

In a series of specialist articles from the field, on topics relating to containers and trucks, you will receive first-hand professional knowledge.

How to secure cargo correctly and what are the basics of cargo securing?

They are developed and presented by Sigurd Ehringer, owner of SE-LogCon:

- VDI certified instructor for load securing

- Reference book author

- 8 years Project Manager

- 12 years with the Bundeswehr (company commander)

- 20 years of sales experience

- since 1996 consultant/trainer in logistics

- 44 years instructor/trainer in various fields

Episode 20: Dunnage bag load securement - Part 1

The set of rules for securing cargo in containers is the CTU-Code 2015. In Appendix 7, Annex 4, an entire chapter is devoted to the securing method with dunnage bags.

It states that dunnage bags is intended to "block" the movement of the load. Conversely, this means that it is a form-fit securing method.

Three pieces of information are required to determine the size of the dunnage bag:

- Cargo weight

- Length, width and height of the load

- Size of the gap

In principle, a distinction can be made between two types:

Standard design based on the “pretzel bag” principle

Cuboid 3D dunnage, which can be used to compensate for larger gaps.

The main objective must always be to prevent cargo movement. This means compensating for the force created by the movement of the charge with the dunnage bag.

In principle, the considerations can be approached from different perspectives:

- From the dimensions and the weight of the load in connection with the expected accelerations, the force from the load and thus the size of the dunnage bag is determined or

- the maximum load weight to be secured is calculated from the existing size of the dunnage bag.

- Depending on the area that results from the load, a suitable dunnage bag is used. In most cases there is no calculation.

In practice, from my experience, the third variant is used most frequently.

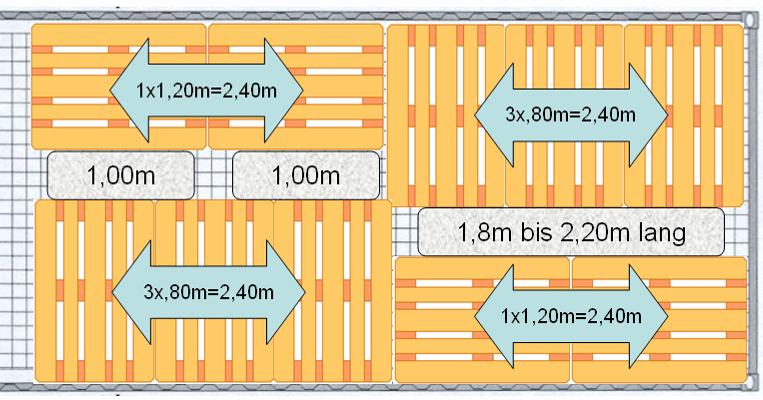

As an example, the classic block of five in a container. There are two options here. Either one big dunnage bag or two small ones.

The big one is useful when the charge is essentially always the same.

The little ones can be used more variably. With the height of the loading unit, the cushion size and the force absorption can be precisely determined.

It is also important to know the relationship between pressure and area.

The greater the pressure and the smaller the area, the greater the acting force. This connection is the most common cause of errors or damage.

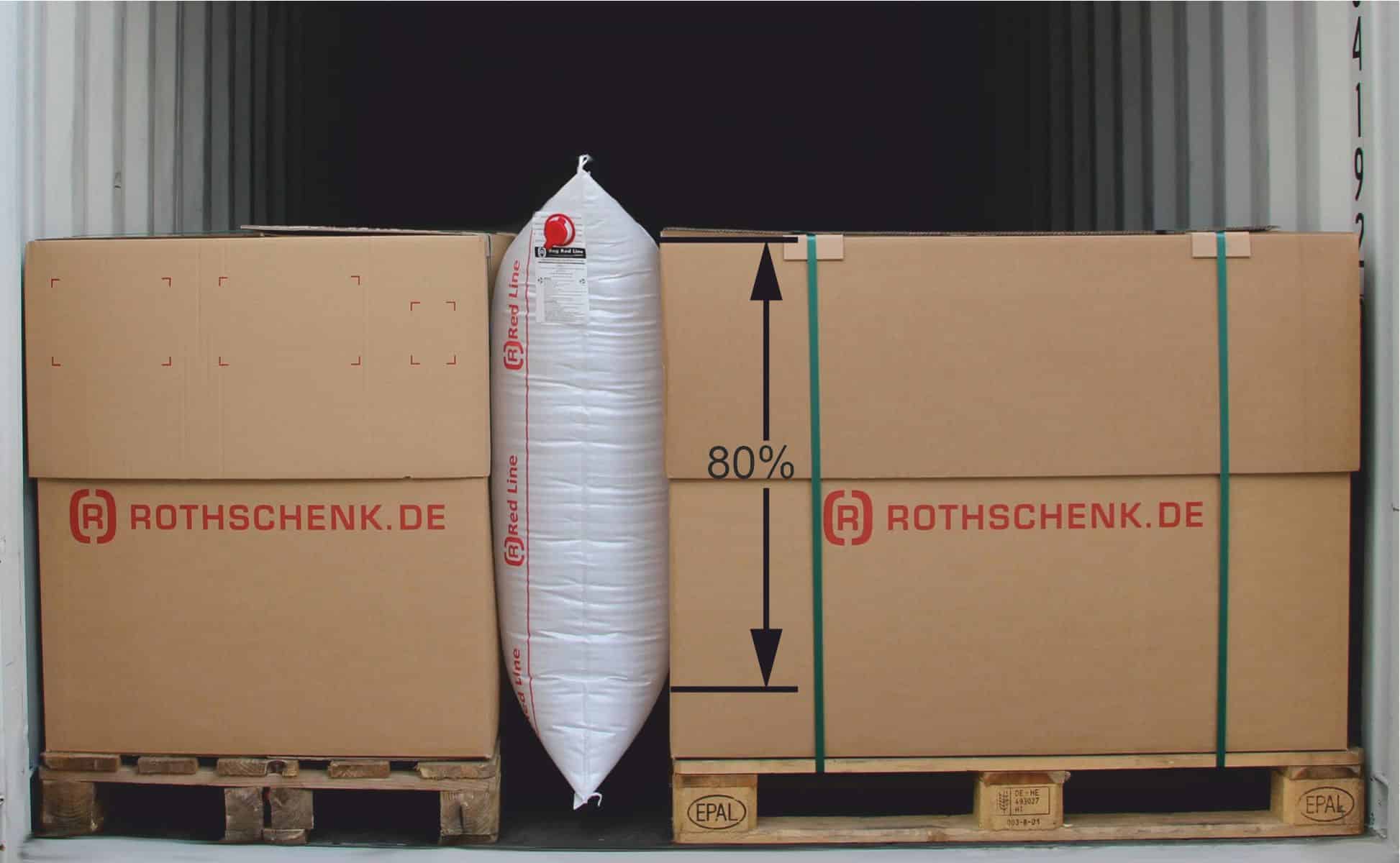

The aim should be that approx. 80% of the dunnage bag surface is in contact with the load, because this enables optimal power transmission/power absorption.

Such situations pose a significant risk to the operability of the dunnage barg.

In the event of an inspection, the container would first be shut down and it would have to be improved. This is usually time and cost intensive.

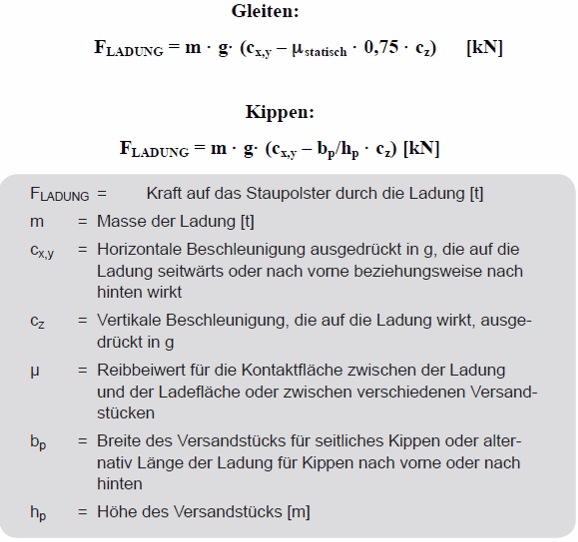

The CTU Code describes the subject very comprehensively and theoretically. Many shippers are overwhelmed with this because all the formulas look complicated, but on closer inspection they are not.

A distinction is made between loads that slide/slip and those that can tilt because they are at different heights. Before you solve the problem of loads of different heights with the laborious calculation of dunnage bags, it is often easier to compensate for the different heights, e.g. by using a pallet substructure.

Only simple solutions are effective in the long run.

Of course, it is important that no technical mistakes are made, such as positioning a dunnage bag where the container is damaged and the padding could be worn through.

It is important to note that in the following CTU Code calculations, the cargo mass is expressed in tons (to) .

The result is then converted into Deca-Newton (daN) because most shippers can do more with it.

Below are a few excerpts from the CTU code with explanations.

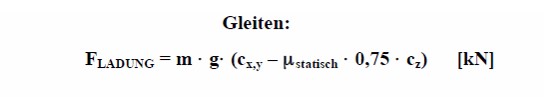

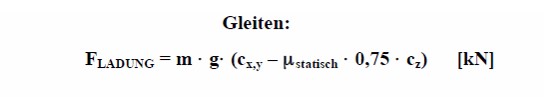

The formula on the right calculates the force generated by a sliding/slipping load.

It should be noted that the coefficient of sliding friction µstatic is in most cases not known or only estimated. Therefore it is reduced by a factor of 0.75.

In sea transport, vertical acceleration Cz can be between 0,2g and 1,8g when pitching the ship. So these are significant differences.

The acceleration when rolling the ship can be up to 0.8g. This corresponds to a roll angle of 38º. A roll period of between 2-3 times per minute is not uncommon.

FS=1to x 9,81 m/s2 x (0.8 - 0.3 x 0.75 x 0,2g)

FS = 9.81kN x (0.8 - 0.045)

FS = 9,81kN x 0,755 = 7,406kN = 740.6daN

FS =1to x 9,81m/s2 x (0.8 - 0.3 x 0.75 x 1,0g)

FS = 9.81kN x (0.8 - 0.225)

FS = 9,81kN x 0,575 = 5.641kN = 564,1daN

FS =1to x 9,81m/s2 x (0.8 - 0.3 x 0.75 x 1,8g)

FS = 9.81kN x (0.8 - 0.405)

FS = 9.81kN x 0.324 = 3,178kN = 317.8daN

In the worst case, with a vertical acceleration of only 0.2g, the force from the charge is more than twice as great as under normal circumstances. The charge calculation should therefore be based on the first example.

When calculating the load force, taking into account the risk of tipping, the length/width (bp) of the package in relation to the height (hp) set. This results in the tipping factor. When tipping, it increases the force generated by the charge.

The number game on the right shows the difference when a Euro pallet is positioned parallel or perpendicular to the direction of acceleration under the same conditions.

A stowage plan helps to make it easier to assess the situation and decide how to stow.

FS =1to x 9,81m/s2 x (0.8 - 0.80m/1.90m x 1,0g)

FS = 9.81kN x (0.8 - 0.42)

FS = 9,81kN x 0,38 = 3.728kN = 372.8daN

FS =1to x 9,81m/s2 x (0.8 - 1.20m/1.90m x 1,0g)

FS = 9.81kN x (0.8 - 0.63)

FS = 9.81kn x 0.17 = 1.668kN = 166.8daN

The topic of dunnage bags will be discussed further in the next episode.

Your Sigurd Ehringer.

As a manufacturer of dunnage bags, correct application is very important to us. Not only with the pictures for marketing, but of course in daily use with the customer.

On our own account:

Rothschenk. That's us.

Rothschenk is a manufacturer of load securing equipment for overseas containers. In the tranquil town of Aub in central Franconia, we develop, test and sell our own load securing equipment such as dunnage bags/padding, Lashing restraint systems, Edge Protectors, Anti-slip Mats, Lashing Straps and drum securement. You can get a small insight into our product world in our Online Shop: [R] SHOP24.

We develop for our customers, to whom also large corporations e.g. from the CHEMICALS-, BEVERAGES- and Automotive industry belong, individual load securing. Therefore we are used to come up with new products and solutions in our own research and test department.

We stand for quality "Made in Germany„. Not only in development, but also in production. Because we are the only manufacturer for load securing with our own production site in Germany. Real "Made in Germany" even.

>> Please use the comment function below for suggestions, additions and also for further questions.

We will, of course, respond promptly and professionally. Your Rothschenk Team

Schreibe einen Kommentar