The set of rules for securing cargo in containers is the CTU Code 2015. In Appendix 7, Annex 4, an entire chapter is devoted to the securing method using dunnage bags.

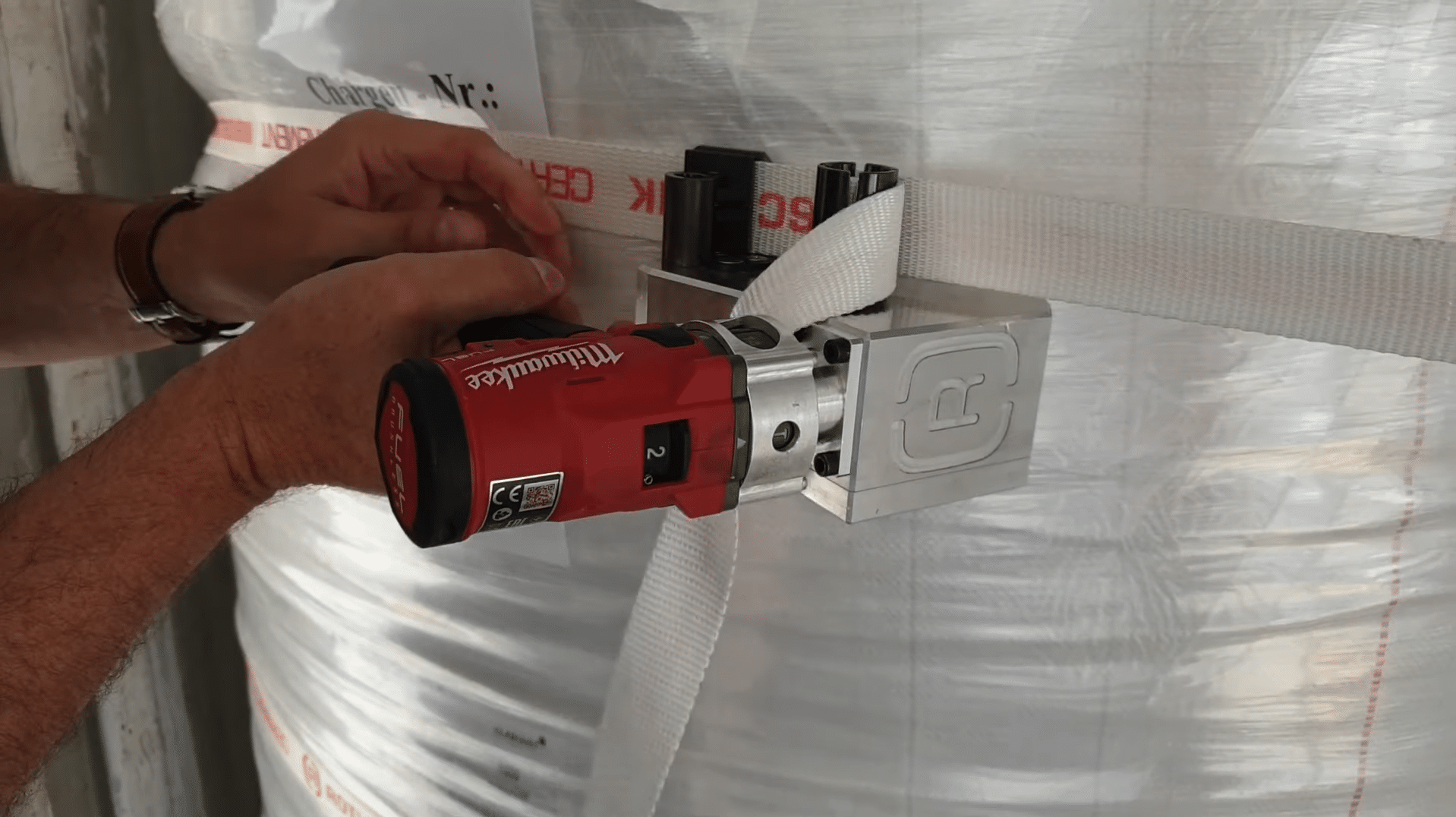

Dunnage bags for load securing are used to fill gaps in the load and thus create a tight fit. They are filled with a compressed air gun or a mobile battery blower and are therefore variable in width and internal pressure.

Furthermore, a simple design is distinguished, which is used for gaps up to 400 mm. So-called 3D dunnage pads are used for larger accumulation gaps, as their cubic design means that they lie more flat against the goods.

The dunnage bags consist of an inner cover made of PE film and an outer cover made of PP fabric or paper. The latter is not recyclable with the inlay and is more sensitive to moisture.