Now 10% off all Ergolash lashing straps save now! Voucher code: ergo10 | Valid until 31.05.2025

Securing cargo in containers using dunnage bags is a common method, but there are still repeated discussions about the type and use of this securing method. Two episodes on this topic have already been published and can be referred to:

Episode 20 dunnage bag Part 1

Episode 21 dunnage bag Part 2

The regulations for securing loads in containers are set out in the CTU Code 2015. In Appendix 7, Annex 4, an entire chapter is devoted to the securing method with dunnage bags.

It states that dunnage bag should “block” the movement of the load. Conversely, this means that it is a positive locking method.

For the following considerations, it is important to define the perspective, as there are certainly differences here and incorrect interpretations should be avoided.

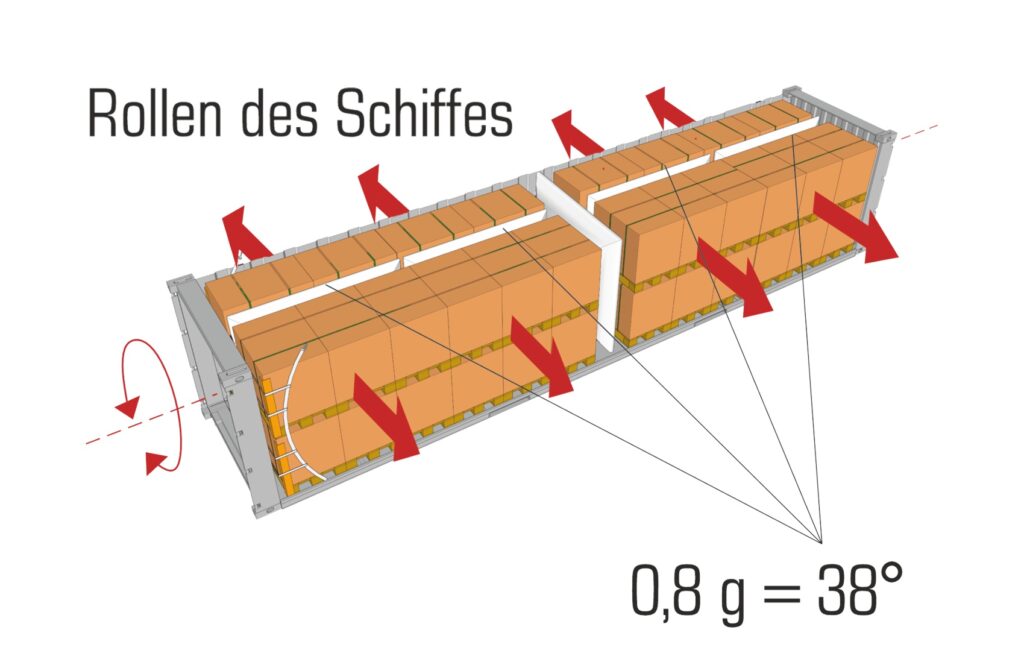

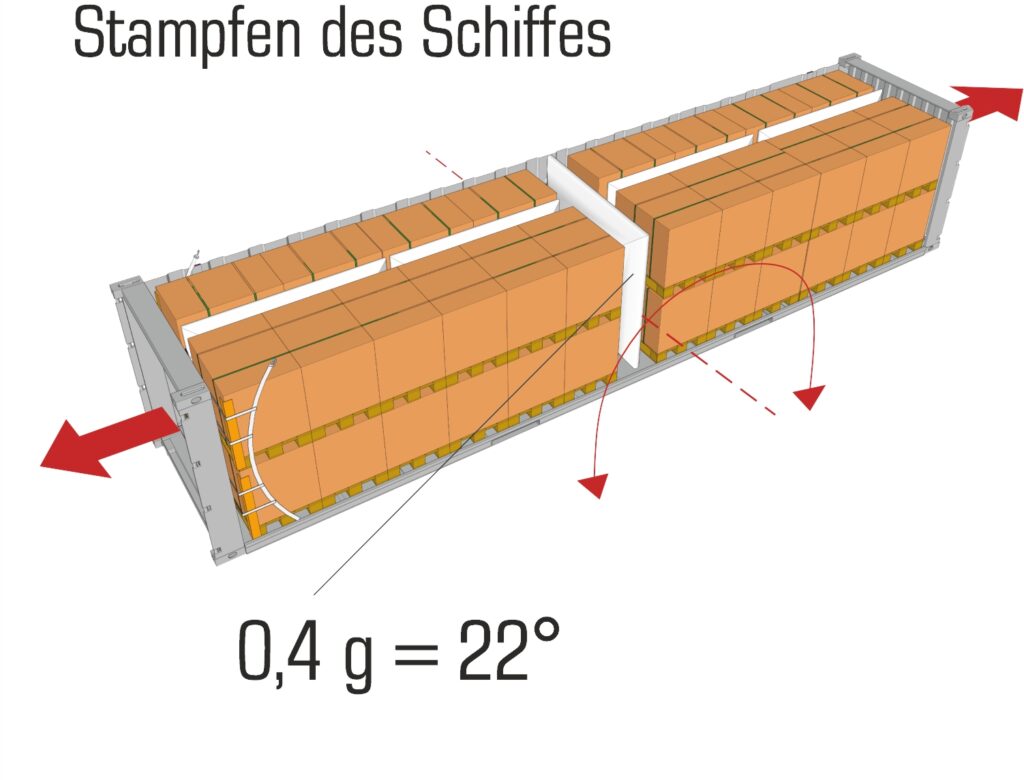

Viewpoint 1: The ship is in the center with the directions longitudinal=direction of travel and transverse to the direction of travel. All data, e.g. accelerations, refer to this. Thus we have the main load transverse to the direction of travel with 0.8g when the ship is rolling and only 0.4g in the longitudinal direction.

Viewpoint 2: The securing devices are at the center. They are positioned in the container according to their proportions. A dunnage bag, which is inserted with its broad side parallel to the longitudinal direction of the container, has been stowed lengthwise. Rotated by 90°, it is stowed crosswise.

The same situation under

Viewing angle 1:

the cushions close gaps across the direction of travel

Viewing angle 2:

The upholstery is positioned lengthways.

The following descriptions are provided from perspective 1.

The CTU code does not specify for which acceleration directions the dunnage bag are permitted or not permitted. However, the graphics in the explanations always show situations in which the dunnage bag compensate for gaps transverse to the direction of travel.

In this case, they must compensate for an acceleration of 0.8g. Congestion situations in which the dunnage bag are placed in gaps along the direction of travel are not described. In this case, they would “only” be exposed to an acceleration of 0.4g.

It is also not described that the dynamic pressure exerted by the cushioning on the cargo generates a frictional force between the cargo items and the container walls, which additionally secures the cargo. The ISO unit “1 bar” pressure results in a load of 1 kg/cm2.

Let’s assume we have a congestion situation like the classic block of 5 and the pallets are 165cm high. The left-hand pallet would have a side area (without Euro pallet) of 120x150cm = 18,000cm2.

If the dunnage bag (level 1) is filled with 0.15 bar, a force of 2,700daN would develop. With a friction of µ=0.2 to the container wall, this would result in a securing force of 540daN. The effect of the corrugations is not taken into account.

When the ship rolls, an even higher securing force would develop, limited in time, because the weight of the entire row of loads also presses against the wall. The weight of the right-hand pallet is therefore added, resulting in the increased frictional force.

Each of these paper rolls weighs approx. 770 kg.

Tipping tests with this load, which was only secured by a dunnage bag, resulted in tipping angles of approximately 45°.

The load was only held in place by the increased friction between the load and the container wall. This friction was generated by the pressure exerted by the cushion.

At this angle, the tangent has the value 1, which corresponds to an acceleration of 1g. The acceleration specified for the container in the longitudinal direction is only 0.4g.

These tests show that the friction between the load elements and the container walls results in values that should not be neglected in load securing.

Quite a few people are concerned that dunnage bag will burst. As a rule, they do not. They are designed and manufactured in such a way that they can withstand several times the pressure caused by the weight of the load or the acceleration.

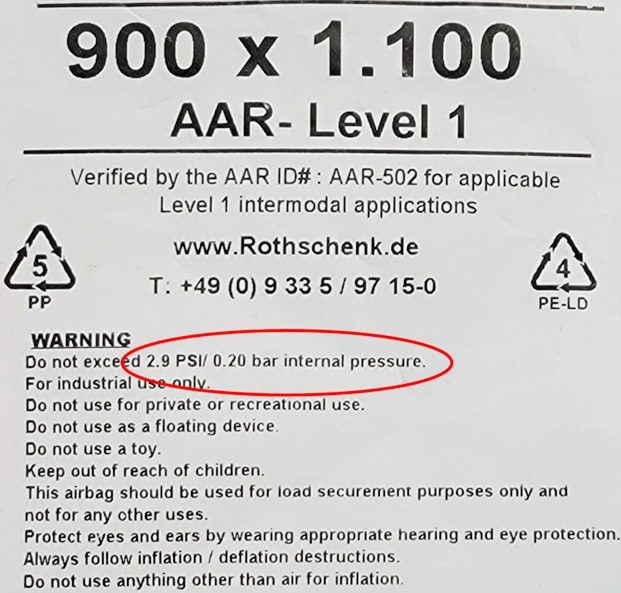

For example, a dunnage bag with level 1, which should compensate for a gap of 30 cm, burst in the test at a pressure of 0.55 bar. However, the maximum working pressure is 0.2 bar. In practice, values between 0.1 and 0.15 bar have proven to be common, as more and more users are filling the dunnage bag with a blower instead of a compressor.

Many manufacturers print handling instructions on the dunnage bag. The extract in the picture shows the 0.20 bar mentioned.

dunnage bag burst, if at all, due to incorrect handling. Sharp edges, nails, rust on the inside walls of containers, chafe marks, sharp parts of the load, etc. These are the dangerous circumstances.

The stevedore has it in his hands and can exert influence.

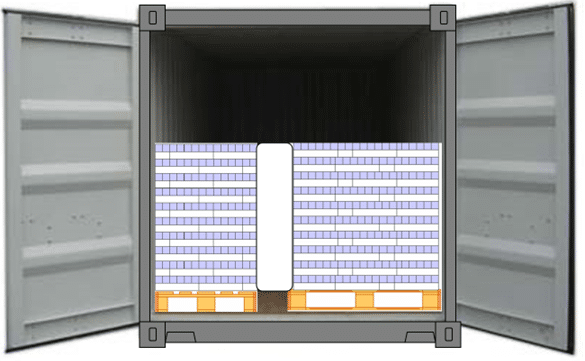

A relatively frequent congestion situation occurs when the container is not completely full and there is a gap (> 15 cm) to the container door.

It is common practice to move this gap inwards and close it with dunnage bags so that the door can be used again for form-fit load securing. In other words, they close gaps that occur along the direction of travel.

Tests have shown that dunnage bag can be used to secure the load lengthways. They can either be used to close gaps or to correct the load distribution in the container so that the overall center of gravity is within the permissible ranges.

The load in this container consisted of several tons of chipboard, which were to be stowed at a distance from the end wall for load distribution reasons.

For the simulation, the 3Ddunnage bag was placed against the container door so that the container could be tilted.

To prevent damage, a protective plate was inserted between dunnage bag and the door.

The tipping process was carried out with a smooth hydraulic movement.

The achieved tilt angle was 39°, which corresponds to an acceleration of 0.81g.

In the longitudinal direction, only 0.4g is required for sea transportation.

The dunnage bag remained undamaged.

It is therefore quite conceivable, dunnage bag in the container in this way. If a form-fit stowage method is achieved and the container including the load behaves like “one piece”, then the risk is comparatively low. It is only increased by incorrect handling.

It is therefore important that all parties involved explore the available options and implement them accordingly. It is not possible to present all possible solutions for load securing in the CTU Code.

VDI-2700 “Load securing on road vehicles” describes this as follows:

“The variety of goods and load securing options cannot always be taken into account in the examples shown. Equivalent load securing devices or those that achieve better securing can also be used as an alternative to those described.

The suitability of load securing aids/methods not regulated by these guidelines can be determined and verified by representative tests in individual cases with documentation by independent experts. The suitability verified in this way must be confirmed by technical information from the manufacturer with reference to the type, date of manufacture/serial number.”

This approach could also be applied to the CTU code, although it is not explicitly mentioned.

The shipper/stevedore is therefore required to check his solutions against the framework conditions specified in the CTU Code and, if necessary, to prove by appropriate tests that the specifications are met.

Let’s get to work!

Yours, Sigurd Ehringer

<< Previous article

Episode 44: Tension belts – discard maturity, labeling and what actually applies?

To the next post >>

Thomas Bauer

✔ Marketing | Web | CI

Rothschenk assortment

Our customer center has only one goal: to turn your problems into solutions. Whether standard stowage cushions, bestsellers or load securing personally tailored to your needs -. we accompany you consistently from A as in field service to Z as in certification. That is our promise to you, as a leader in our industry.

We attach great importance to professional cargo securing. That is why we have our own production, which ensures reliable operation through modern manufacturing technologies and strict quality control. Thus, we offer our customers a comprehensive and high-quality range of services in the field of transport logistics.

DIN ISO 9001:2015, EMAS and Ecovadis are not foreign words to you? Then it's time to work with the best.

You don't take any risks with us - we have been awarded the Platinum Medal on the EcoVadis sustainability rating platform.

As a load securement company, we are proud to have several certifications that validate our sustainability efforts and our commitment to environmental protection and social responsibility. For you as a purchaser, this means that we demand and promote the implementation of high environmental and social standards both within the company and along the supply chain.

G&H GmbH Rothschenk

Industriestrasse 5 & 7-10

97239 Aub

Phone: +49 9335 97 15 – 79

Fax: +49 9335 97 15 – 15

E-mail: info@rothschenk.de

Collection/delivery

Mon – Fri: 8:00 – 15:00

Office hours

Mon – Thu: 8:00 – 17:00

Fri: 8:00 – 13:00

G&H GmbH Rothschenk

Industriestrasse 5 & 7-10

97239 Aub

Phone: +49 9335 97 15 – 0

Fax: +49 9335 97 15 – 15

E-mail: info@rothschenk.de

Collection/delivery

Mon – Fri: 8:00 – 15:00

Office hours

Mon – Thu: 8:00 – 17:00

Fri: 8:00 – 13:00

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information