Episode 33: Problem Treatments - Using Blocking Agents Correctly

The most common means of transport in Europe today is the semi-trailer.

Compared to articulated trains, it has the advantage of a continuous loading area, a larger payload and it is easier to maneuver.

In this article, I address problem treatments associated with fuses in this type of setup.

About the author:

In a series of specialist articles from the field, on topics relating to containers and trucks, you will receive first-hand professional knowledge.

How to secure cargo correctly and what are the basics of cargo securing?

They are developed and presented by Sigurd Ehringer, owner of SE-LogCon:

- VDI certified instructor for load securing

- Reference book author

- 8 years Project Manager

- 12 years with the Bundeswehr (company commander)

- 20 years of sales experience

- since 1996 consultant/trainer in logistics

- 44 years instructor/trainer in various fields

Episode 33: Problem Treatments - Using Blocking Agents Correctly

The major manufacturers such as SchmitzCargobull, Krone or Kögel build their trailers with comparable loading dimensions.

The loading width is mainly 2.48m, the loading length 13.60m and the loading heights 2.70m.

Deviations are possible depending on the superstructure type, but do not play a role for the problem statement.

The inner load width is based on the dimension of the Euro pallet.

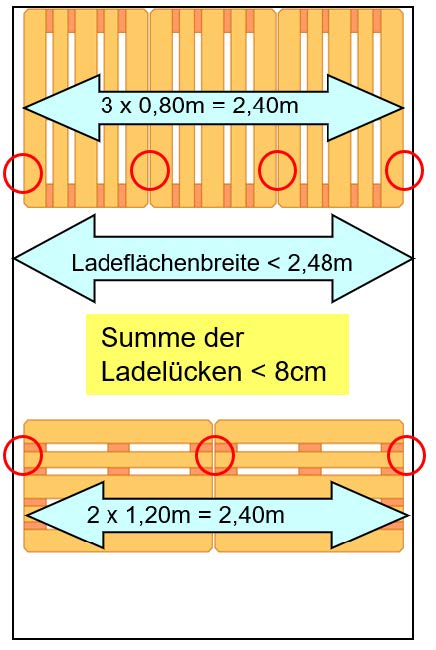

The stowage pattern can be illustrated using the adjacent graphic. With an inside loading width of 2.48 m, this results in a gap total of 8 cm, divided into 3 or 4 gaps, depending on how stowage is carried out.

The maximum number of pallets can also be calculated from this scheme.

Longitudinally dammed:

13,60m / 1,20m * 3 = 33 pallets

Cross dammed:

13,60m / 0,80m * 2 = 34 pallets

Longitudinal or transverse is in the view of the observer, depending on whether he is arguing as a truck or forklift driver.

The technical payload of 27,000kg specified in the certificates for the standard semitrailer for calculating the body strength is, of course, not the weight that can be expected when loading.

The practical payload is the weight that can be loaded without overloading the vehicle. As an example, 25,500kg can be calculated.

However, each company must determine this weight itself so that there is a secure basis for planning, because this depends on various factors. For example, if the load weight can change within limits due to production.

To continue the considerations, the practical payload of 25,500kg can be divided by the number of pallets. Calculated with 33 pallets, the average weight per pallet is 773kg, or with 34, 750kg.

As soon as the loading units exceed this weight, the semitrailer can no longer be completely loaded because it would otherwise be overloaded.

The following loading units are typical examples:

- Octabins

- Bigbags

- Beverage pallets with 40 crates

- Bagged cement

- IBC`s etc.

This means that with this constellation, the truck will not be completely full and the distance to the rear portal will be greater than 15cm. It may also be necessary to move the load away from the end wall and back because of the load distribution. At this point, it is necessary to think about the way the load is secured.

There are only two variants:

1. the vehicle is equipped with on-board securing devices, such as locking beams, the total securing force of which must amount to at least 30% of the technical payload, or

2. it must be secured using conventional securing methods as described in VDI 2700ff.

Unfortunately, the practice is often that the semi-trailer is only equipped with clamping boards (partition closures), whose blocking force is just 400daN, or in the box body with clamping rods, whose blocking force is 150daN. This is too little in most cases.

I would like to point out to all vehicle owners that §30StVO obliges him to equip the vehicle with securing means. Their total securing forces should be at least 30% of the technical payload. If this is not the case, the problems with the load securing are pre-programmed.

Examples of securing devices and their blocking force

Partition locks (clipboard)

friction-dependent

Blocking force as new 400daN

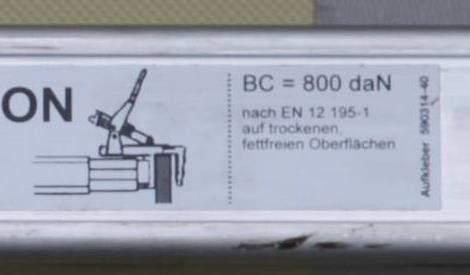

Clamping bar

friction-dependent

Blocking force as new 800-1.000daN

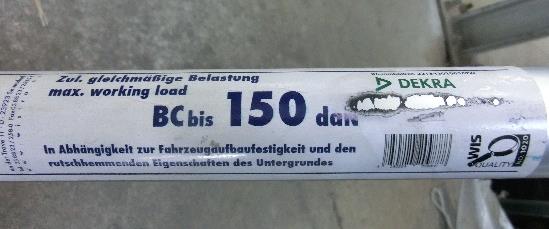

Clamp bars

friction-dependent

Blocking force as new 150daN

Blocking bar

vehicle specific

positive locking

Blocking force as new 1.000 - 4.500daN

It is therefore important that the responsible shipper thinks about how he wants/needs to secure his cargo before procuring the transport space.

The securing devices on the vehicle side, which are typical of the system, generally have the greatest securing forces. The means that can be used in different vehicle variants are often designed to be weaker.

If the above variant 1 is not possible or cannot be implemented, variant 2 must be used. Variant 1 is a securing device that represents a form-fit securing method. As a rule, it is the simplest, safest and quickest method of securing the load.

The description of variant 2 will appear in one of the next LaSi blogs.

A good approach is to create a vehicle/equipment specification that is company-specific:

- Vehicle type/body type

- Type and design of the vehicle's systemic securing means

- Type and number of tension belts, edge protectors and anti-slip mats

- Other equipment required

In another installment of the LaSi blog, I'll go into more specific charges where the so-called domino effect can occur.

Your Sigurd Ehringer.

Clamping board, bars, beams or locking beams, what is the difference?

For good advice, it's not just the customers who need to know the difference.

On our own account:

Rothschenk. That's us.

Rothschenk is a manufacturer of load securing equipment for overseas containers. In the tranquil town of Aub in central Franconia, we develop, test and sell our own load securing equipment such as dunnage bags/padding, Lashing restraint systems, Edge Protectors, Anti-slip Mats, Lashing Straps and drum securement. You can get a small insight into our product world in our Online Shop: [R] SHOP24.

We develop for our customers, to whom also large corporations e.g. from the CHEMICALS-, BEVERAGES- and Automotive industry belong, individual load securing. Therefore we are used to come up with new products and solutions in our own research and test department.

We stand for quality "Made in Germany„. Not only in development, but also in production. Because we are the only manufacturer for load securing with our own production site in Germany. Real "Made in Germany" even.

>> Please use the comment function below for suggestions, additions and also for further questions.

We will, of course, respond promptly and professionally. Your Rothschenk Team

Schreibe einen Kommentar