Episode 21: Stowage bag load securing - Part 2

Why is it that in most cases there are no problems, even though hardly anyone bothers to do the math?

This can be proven by calculations.

Provided that, as described in part 1, no technical errors are made.

About the author:

In a series of specialist articles from the field, on topics relating to containers and trucks, you will receive first-hand professional knowledge.

How to secure cargo correctly and what are the basics of cargo securing?

They are developed and presented by Sigurd Ehringer, owner of SE-LogCon:

- VDI certified instructor for load securing

- Reference book author

- 8 years Project Manager

- 12 years with the Bundeswehr (company commander)

- 20 years of sales experience

- since 1996 consultant/trainer in logistics

- 44 years instructor/trainer in various fields

Episode 21: Stowage bag load securing - Part 2

As a basic principle, the securing force through the cushion must be at least as great as the force arising from the load, and the load must not move.

What do you think these barrel pallets would do with a roll angle of 37º?

They would naturally slip or tip. A rolling period of up to 2-3 times per minute is not unusual.

The roll angle 38º would correspond to the maximum acceleration of 0.8g transverse to the direction of travel.

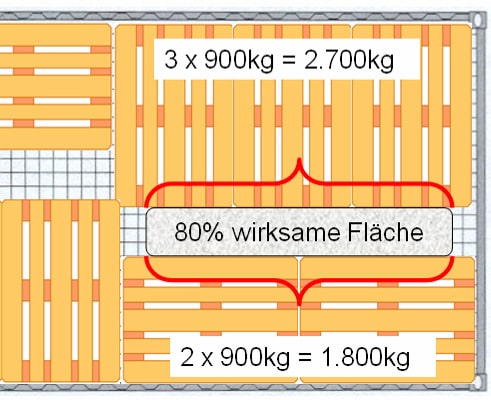

Let's take as an example the classic block of five made of Euro pallets, as described in Part 1.

The load units weigh 900kg each and are 1.60m high. The side length of the two blocks is 2.40m each.

The question now is, how large must the dunnage cushion be so that the force from the load is compensated with 80% cushion area.

Calculate cushion area:

Side length:

2.40m x 0.8 = 1.92m

Height:

1.60m x 0.8 = 1.28m

Gap width:

0,34m

The width of the gap between the loading units is calculated from the internal width of the container of 2.34m, minus the pallet dimensions of 1.20m + 0.80m, i.e. 0.34m.

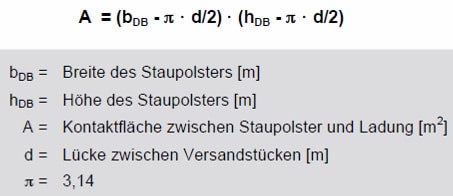

The formula from the CTU code for the effective area of the cushion is:

In the formula, both the width (bDB) as well as the height (hDB) and the gap width (d) contain

To be able to determine the respective initial dimension, the elements of the formula must be rearranged.

From = (bDB - π - d/2) becomes (bDB + π - d/2) and from (hDB - π - d/2) becomes (hDB + π - d/2).

Staying with the example described, the manufacturing dimensions for the cushion are obtained from the following calculation:

Length/Width = (bDB + π - d/2) = 1.92m + 3.14 x 0.34/2) = 1.92m + 0.53m = 2.45m

dunnage bag height = (hDB + π - d/2) = 1.28m + 3.14 x 0.34/2) = 1.28m + 0.53m = 1.81m.

In the next step, the permissible load on the cushion must be compared with the force from the load. There must be at least equilibrium.

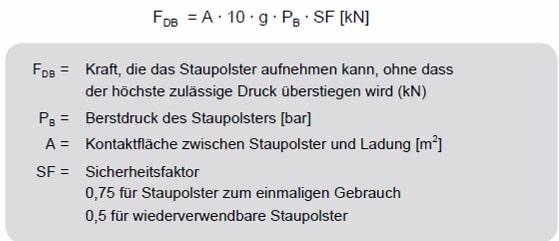

The CTU code specifies the following formula for pad loading:

FDB = A - 10 - g - PB - SF [kN], where PB is the allowable burst pressure of the cushion and SF is the safety factor of 0.75 for one-way dunnage bags.

The value for the bursting pressure must be requested from the supplier.

The value of PB = 0.55bar applies to a standard cushion with level 1 and is used representatively in my calculation

Using the values from the previous example, we get: FDB = 1.92 x 1.28 x 10 - 9.81m/s2 - 0.55 - 0.75 [kN] =67.77kN.

The force that this cushion can oppose a charge is therefore 6,777daN.

The next step is the calculation of the force, which results from the charge.

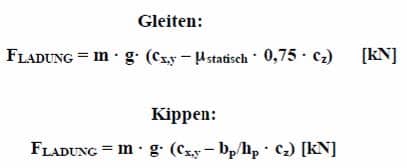

Here are the formulas from the CTU Code for a sliding/tipping load. However, it is particularly important to note that the weight is in tons and not as

is specified in kilograms as usual.

The values from the example used in the calculation result in the following:

FCargo = 2.7to x 9.81m/s2 x (0.8 - 0.3 x 0.75 x 0.2) [kN].

FCargo = 26.45 x (0.8 - 0.045) [kN]

FCargo = 26,45 x 0,755 = 19,97kN = 1.997daN

The securing force (6,777daN) resulting from the stowage cushion is therefore 3.3 times greater than the force (1,997daN) resulting from the cargo.

Conversely, this means that if the size of the cushion is selected so that the load is held flat, i.e. it cannot tip, slide or turn, the securing force of the cushion is generally always sufficient.

Your Sigurd Ehringer.

Do you already know our online courses for load securing? Under the label [R] Instructor we offer Training for trucks/containers according to CTU Code and VDI 2700 ff.

On our own account:

Rothschenk. That's us.

Rothschenk is a manufacturer of load securing equipment for overseas containers. In the tranquil town of Aub in central Franconia, we develop, test and sell our own load securing equipment such as dunnage bags/padding, Lashing restraint systems, Edge Protectors, Anti-slip Mats, Lashing Straps and drum securement. You can get a small insight into our product world in our Online Shop: [R] SHOP24.

We develop for our customers, to whom also large corporations e.g. from the CHEMICALS-, BEVERAGES- and Automotive industry belong, individual load securing. Therefore we are used to come up with new products and solutions in our own research and test department.

We stand for quality "Made in Germany„. Not only in development, but also in production. Because we are the only manufacturer for load securing with our own production site in Germany. Real "Made in Germany" even.

>> Please use the comment function below for suggestions, additions and also for further questions.

We will, of course, respond promptly and professionally. Your Rothschenk Team

Schreibe einen Kommentar