Episode 8: Form fit in the container

Securing cargo in containers is not really a problem, but inspection practice and the damage rate show that many shippers/stevedores have difficulties with "knowing how!

In this episode, I will explain the principles of form-fit stowage/packing and the options for implementing them. The difference between frictional and positive locking has already been explained in many places, which is why it will not be discussed here.

Positive locking in the container means that the cargo should/should not move relative to the container due to accelerations generated mainly by the rolling and pitching of the ship.

About the author:

In a series of specialist articles from the field, on topics relating to containers and trucks, you will receive first-hand professional knowledge.

How to secure cargo correctly and what are the basics of cargo securing?

They are developed and presented by Sigurd Ehringer, owner of SE-LogCon:

- VDI certified instructor for load securing

- Reference book author

- 8 years Project Manager

- 12 years with the Bundeswehr (company commander)

- 20 years of sales experience

- since 1996 consultant/trainer in logistics

- 44 years instructor/trainer in various fields

Episode 8: Form fit in the container

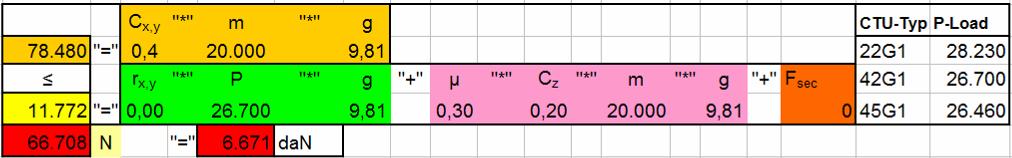

The calculation of the load securing according to the CTU Code 2015 is made with the following formula:

C x,y * m * g ≤ r x,y * P * g + µ * Cz * m * g + Fsec

The formula consists of the following elements:

- Force from the charge = C x,y * m * g

- Retention force of the container = r x,y * P * g

- Force from friction = µ * Cz * m * g

- Force from securing means: = Fsec

Note: The restraining force of the container is calculated with the resistance coefficient r x,y and the payload P (it can be found on the container door). See also LaSi blog episode 3.

To better understand the formula, it can be thought of as the contents of scales.

The left scale shell contains the sum of the forces resulting from the load weight (m) multiplied by the acceleration direction (C x,y) and the earth's gravitational force (g), results.

The right scale shell includes three components:

- Securing forces resulting from the restraining force of the container superstructure,

- + Securing force from friction between cargo and container floor

- + Securing forces resulting from securing means (e.g.: lashings).

Their sum must be equal to or greater than the sum in the left pan.

If you compare the elements in the right-hand pan, you will see that the form-fit securing, in which the forces from the container superstructure are used, is the most effective.

Since it is common practice in load securing to state the forces in daN, the following example calculation states the weight in kg and converts the result into daN.

Example:

A 20,000kg load stowed in a 42G1 container. The positively stowed load is transported in longitudinal direction, with an acceleration of Cx=0.4g, is calculated. The retention force (rx) of the container door is 0.6 * of the payload (P) 26,700kg.

If the distance between the container door and the cargo were greater than 15cm, i.e. no tight fit, the calculation would look like this: rx is set equal to 0, the calculation would look like this:

Would the security forces Fsec provide at least 66,708N, the balance would be in equilibrium and the load adequately secured. Of course, more securing force would also mean more safety and reserve. So do not sew too tightly.

The more elegant solution would be to change the stowage plan by moving the gap inside the container and closing it with stowage aids (e.g. stowage cushions/wood/empty pallets).

The form closure to the container door (rx=0,4) is then given again and the calculation looks as follows:

It is useful if the stowage plan takes into account that there should be a load at the container door which can also transfer the forces well and over a wide area. A single standing pallet (which is often seen) would not serve this purpose.

Even if we use the longitudinal acceleration instead of the Cx=0,4g for the ship with 0,8g for the full braking of the truck and calculate the vertical acceleration Cz with 1, the result would still be in the green range, as the calculation shows.

There is therefore much to be said for not lightly abandoning the form closure for reasons of time or cost.

How can this be accomplished:

- Fill the container with cargo without gaps (e.g. bulk cargo).

- stow/pack the load so that the gap sum is less than 15cm

- Compensate gaps with dunnage

- Compensate for gaps by form-fit securing with lash straps.

Regarding 1: Filling the container with bulk material is in principle a simple solution, but it also has its pitfalls if the bulk material is very free-flowing (coffee/bean, etc.). Then the filling level must be as high as possible.

Regarding 2: to stow and pack the cargo in such a way that the sum of gaps in all directions is less than 15cm requires that the dimensions of the packages or load units correspond to the container dimensions. If, as is often the case, Euro pallets are stowed, gaps will inevitably result. If gaps cannot be avoided, special attention must be paid to securing the load units. The load units must be dimensionally stable and stable against tipping.

Regarding 3: Compensating for gaps with dunnage is common practice. The technically elegant solution is to use air-filled dunnage to fill the gaps and thus restore the form fit. However, this method also has its pitfalls. The 2015 CTU Code devotes a separate chapter to airbags (Appendix 7 - Annex 4) with many formulas, which are rather difficult to implement for the practitioner. The risks lie mainly in the inadequate application of pads, such as: wrong size, contact on sharp edges; chafing, etc.

Another installment of the LaSi blog will focus more intensively on this topic.

Gaps, of course, can be compensated with wooden dunnage.

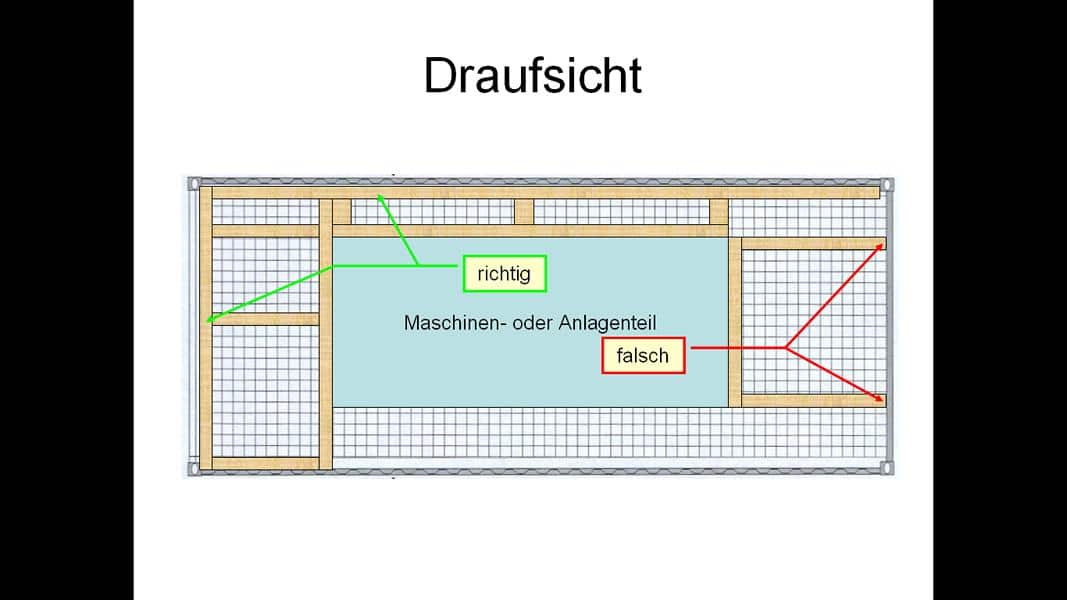

Here, it is particularly important to ensure that the forces are always transferred to the container walls in a planar manner and not as point loads.

You can see a corresponding example of correct and incorrect application of wooden bracing in the drawing.

If dunnage is used, the rules for nailing and screwing must also be followed so as not to weaken the joints.

A good nail driven in the wrong way (e.g. into the end grain (red circle)) will provide less securing force than expected. Timber with a tree edge (red arrow) can lead to quarantine in certain countries such as Australia.

Pressing dunnage into the corrugations of the container wall in this way creates more damage than it provides useful securing force. Unfortunately, this is a common application, even in professional stevedoring operations.

The actual securing force is undetermined and no reliable data can be found on this. Therefore, this method should not be used unless appropriate tests have produced repeatable results and the handling is clearly described.

Empty pallets are also a popular solution. However, if the impression could be created that predominantly empty pallets are transported, a better solution should be sought.

Styrofoam or rigid foam blocks are also suitable as gap fillers, especially if the same congestion situation occurs more frequently.

Re 4: Compensating for gaps by form-fit securing with lashing straps is a common method, especially for machinery and equipment. However, the load-bearing capacity of the lashing eyes in the container and the lashing force of the securing equipment must be taken into account here.

Depending on the manufacturer, it is important to note whether the breaking load or the MSL (maximum securing load) is specified. The CTU Code 2015 gives details in Annex 7 Chapter 2.4.2 on how the MSL is calculated for certain securing devices. For example, for single-use belts, an MSL of 75% of the breaking load at a maximum elongation of 9% is permissible, while for reusable belts the MSL may only be calculated at 50%.

The MSL of the securing means must harmonize with the MSL of the lashing or anchorage points and attention must be paid to the weakest link of the chain in each case.

Of course, the lashing angles α and β must also be taken into account for each lashing and the resulting effective forces must be calculated.

Your Sigurd Ehringer.

As a test container for Rothschenk, I see professional load securing all the time. But I also know that many of my colleagues out there have to transport inadequately secured goods.

It would be good if more shippers would pay attention to the correct application of the basic loading rules ;-)

On our own account:

Rothschenk. That's us.

Rothschenk is a manufacturer of load securing equipment for overseas containers. In the tranquil town of Aub in central Franconia, we develop, test and sell our own load securing equipment such as dunnage bags/padding, Lashing restraint systems, Edge Protectors, Anti-slip Mats, Lashing Straps and drum securement. You can get a small insight into our product world in our Online Shop: [R] SHOP24.

We develop for our customers, to whom also large corporations e.g. from the CHEMICALS-, BEVERAGES- and Automotive industry belong, individual load securing. Therefore we are used to come up with new products and solutions in our own research and test department.

We stand for quality "Made in Germany„. Not only in development, but also in production. Because we are the only manufacturer for load securing with our own production site in Germany. Real "Made in Germany" even.

>> Please use the comment function below for suggestions, additions and also for further questions.

We will, of course, respond promptly and professionally. Your Rothschenk Team

Schreibe einen Kommentar