Episode 7: The incoming inspection of the container

A considerable part of all global general cargo transports is handled by container. Millions of such metal boxes are on the move by sea, rail and road.

Everywhere they are subject to special transport stresses and when loading, sometimes shippers have no inhibitions about handling them with little care for the material.

Although there are globally applicable rules for testing and repairs for the container and actually everyone should be okay, at least in theory, all boxes have more or less major blemishes.

Therefore, it is mandatory to subject the container to incoming inspection before loading.

About the author:

In a series of specialist articles from the field, on topics relating to containers and trucks, you will receive first-hand professional knowledge.

How to secure cargo correctly and what are the basics of cargo securing?

They are developed and presented by Sigurd Ehringer, owner of SE-LogCon:

- VDI certified instructor for load securing

- Reference book author

- 8 years Project Manager

- 12 years with the Bundeswehr (company commander)

- 20 years of sales experience

- since 1996 consultant/trainer in logistics

- 44 years instructor/trainer in various fields

Episode 7: The incoming inspection of the container

The CTU Code 2015, the international regulations for handling containers, assigns responsibility for this to the shipper or packer in Chapter 4.2.3. It states:

"The packer shall ensure that the CTU is inspected prior to packing and that the condition of the CTU is suitable for the cargo to be transported". More stroke enumerations follow.

What would a customer think if he received his rather expensive goods in such packaging? He would probably think: hopefully my goods are undamaged and take a much closer look to see if everything is in order.

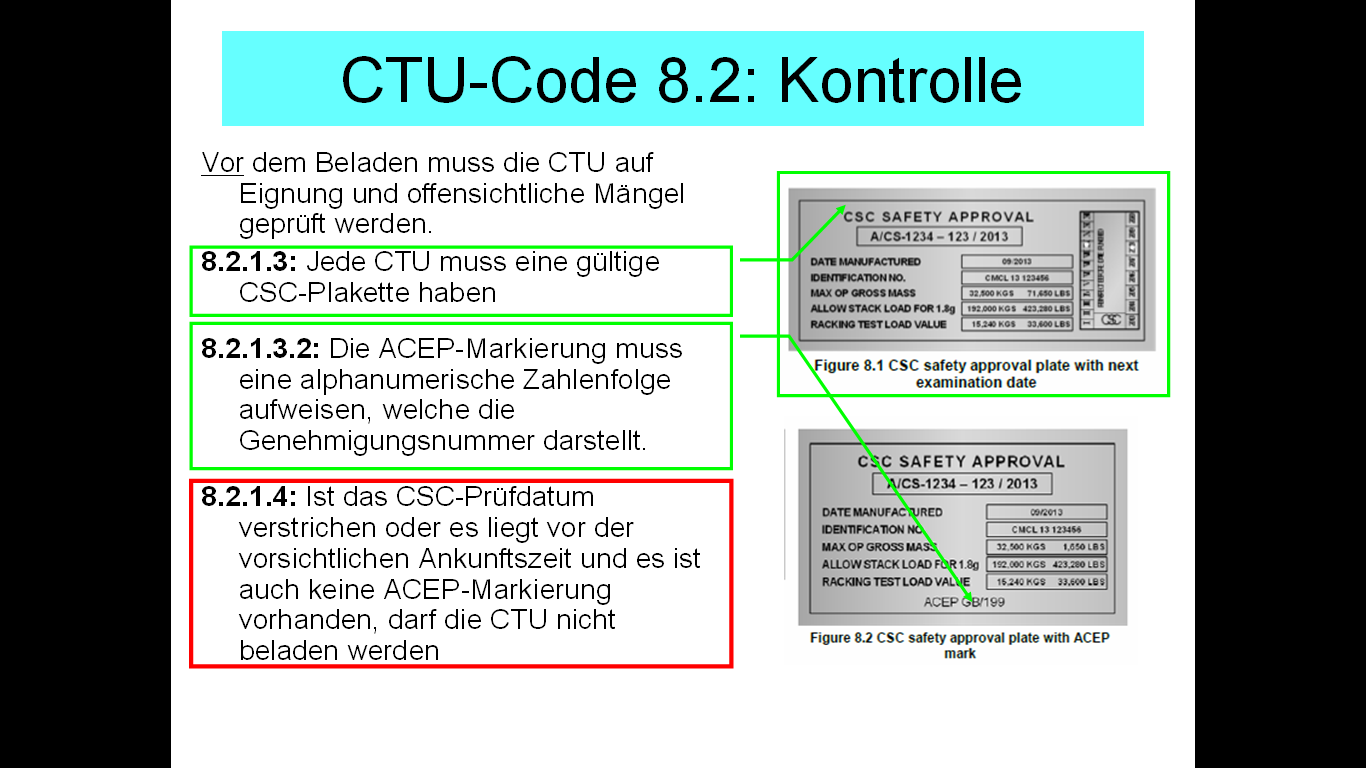

In chapter 8.2, the regulations explain the control of the cargo transport unit, but remain diffuse in the details.

Therefore, it is necessary for the loading company to study the matter and determine for its needs which type of CTU is suitable and what other characteristics must be met.

The following statements are the result of many container inspections or loading escorts on the practice front.

Here, the decisive switch is often already set incorrectly by the truck driver, who opens the doors of the container after arrival, folds it and then drives it to the ramp.

The important check of the CSC sticker is then no longer so easily possible. The driver does it this way because it is common practice with many shippers/packers and an incoming inspection is not carried out.

Container control should be considered in two steps:

- the incoming inspection with the aim of bringing about a decision whether to accept or reject the container.

- documentation of loading with the loading sequence, load securing measures, load distribution and securing against falling out, if this would be necessary.

These two phases should be described unambiguously for the controller, with clear criteria, in order to make control easier for him.

The following considerations deal with input control.

It is not uncommon for companies to have to pay for repairs to containers even though they did not cause them.

Conversely, if the incoming inspection is not carried out and therefore no defects are found, this means that the container was in order when it was accepted and the damage was caused by the packer during its service life.

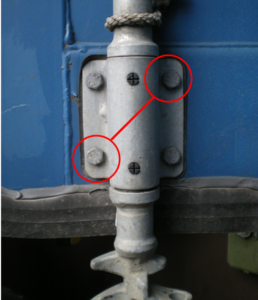

The locking lever and lever latch must also be riveted.

After that, the whole container should be visually inspected. Check not only all sides from the outside, but also the bottom from below.

Such damage should be documented in any case, especially since it can lead to problems when using dunnage pads.

This is because the hard rust surface can cause loss of pressure in the dunnage due to scuffing.

A container must also be tested for leaks. Here, the best solution is the two-man method. One climbs into the container, the other locks the door completely. Now it must be completely dark inside.

Diffuse light may penetrate through the pressure compensation openings in bright sunlight, but this is not critical. Otherwise, any leakage, no matter how small, would be detected by the incidence of light.

The container must also be clean and odorless. If the container needs to be aired before loading, the time required for this should not be counted towards the loading time in consultation with the shipping company.

The CTU Code gives guidance on this in various places, but especially in item 12.1.6.

Particular attention must be paid to indications as to whether a container has been fumigated. This is because some packers do not fulfill their labeling obligation in this respect.

Taped-off pressure equalization openings are a clear sign of gassing. They are often also sealed from the inside. Caution is therefore always advisable.

The aim must be to ward off claims for damages for defects that were already present.

Deficiencies should therefore be recorded in a checklist and, if necessary, photographed. In addition, it may also make sense to agree with the shipowner or forwarder on how to proceed. After all, this is always cheaper than having to pay the costs of expensive repairs afterwards due to a lack of evidence.

Your Sigurd Ehringer.

Many people are not aware that professional load securing starts with the acceptance of a container. Using top products is one thing, but the basics must also be right.

On our own account:

Rothschenk. That's us.

Rothschenk is a manufacturer of load securing equipment for overseas containers. In the tranquil town of Aub in central Franconia, we develop, test and sell our own load securing equipment such as dunnage bags/padding, Lashing restraint systems, Edge Protectors, Anti-slip Mats, Lashing Straps and drum securement. You can get a small insight into our product world in our Online Shop: [R] SHOP24.

We develop for our customers, to whom also large corporations e.g. from the CHEMICALS-, BEVERAGES- and Automotive industry belong, individual load securing. Therefore we are used to come up with new products and solutions in our own research and test department.

We stand for quality "Made in Germany„. Not only in development, but also in production. Because we are the only manufacturer for load securing with our own production site in Germany. Real "Made in Germany" even.

>> Please use the comment function below for suggestions, additions and also for further questions.

We will, of course, respond promptly and professionally. Your Rothschenk Team

Schreibe einen Kommentar