Episode 6: Bay- or headlashing - What does it mean?

Load securing is an inexhaustible topic and anyone who is on the road with alert eyes has certainly realized that more loads are being secured than in the past.

Even agriculture is using more and more hedging agents. Whether they are effective, however, is questionable. Perhaps this can be described with the following anecdote.

Two mothers are talking about their musical children.

One: my son plays the piano and yours?

The other proudly says: mine plays the piano too!

Says the first: soso, but he plays wrong.

About the author:

In a series of specialist articles from the field, on topics relating to containers and trucks, you will receive first-hand professional knowledge.

How to secure cargo correctly and what are the basics of cargo securing?

They are developed and presented by Sigurd Ehringer, owner of SE-LogCon:

- VDI certified instructor for load securing

- Reference book author

- 8 years Project Manager

- 12 years with the Bundeswehr (company commander)

- 20 years of sales experience

- since 1996 consultant/trainer in logistics

- 44 years instructor/trainer in various fields

Episode 6: Bay- or headlashing - What does it mean?

Physics remains physics

The correct application of securing means is what makes the measure effective in the first place. To do this, you have to understand what is actually happening.

The §22 StVO describes the conditions: "not slip, fall over, roll back and forth, fall down or produce avoidable noise even during emergency braking or sudden evasive action.“

This makes it clear that the load must not move parallel to the loading area in the direction of travel during emergency braking and must not move parallel to the loading area in the direction of travel during evasive action.

This movement must be prevented by the securing means.

Friction²?

If no securing equipment is used, this movement is secured solely by the friction between the load and the loading surface. The measure of this friction is the coefficient of friction µ. The cleaner the loading surface, the higher the coefficient of friction.

At this point, it is important to explain the difference between frictional and positive locking by means of an example.

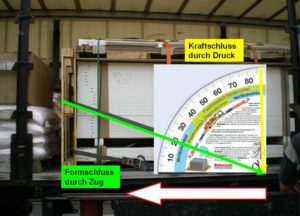

In the picture, the red arrow points in the direction of travel and this is also the direction in which the load would move during full braking.

If a belt (yellow arrow) is attached at right angles (90º) to the possible direction of movement of the load, its pre-tensioning by pressure increases the weight of the load and thus a higher frictional force is created between the load and the loading surface. This is frictional.

If the angle (< 90º) changes towards 0º, the belt (green arrow) is subjected to increasing tensile stress during a loading movement. This is positive locking.

+/- 45° ?

If the lashing angle is greater than 0º but less than 90º, the securing force is divided into a positive and a non-positive component. At around 45º, the ratio changes.

The Tie-down lashing is a friction-locked, while the Bay lashing/ Headlashing and the Direct lashing is a positive locking method. For this purpose, it is also important to distinguish between the different indications on a belt label.

The information outlined in yellow is for the Tie-down lashing to be used. This belt can provide a securing force of 600 daN x 0.3 = 180 daN when lashed down with an assumed coefficient of friction of µ=0.3 (broomless loading area) and a lashing angle of 90º.

For the Direct lashing the information outlined in green must be used. The belt can provide a securing force of 2,500daN in straight pull, assuming a lashing angle of 0º.

At Bay lashing/head lashing this value increases to 5,000daN because the belt is hooked into two lashing eyes on the loading area. The limitation is the load capacity of the lashing eyes. If these have a strength of 2,000daN (standard), the securing force is reduced to 4,000daN.

Headlashing

Now the preconditions for a more detailed explanation of book lashing and head lashing have been created.

The Headlashing is an excellent method of securing a load to the rear. The pallets standing on edge form a surface for better force transmission and hold the belts in position. In the example on the right, a securing force of 8,000daN can be roughly assumed without taking into account the exact angles and friction.

However, the lashing angles must always be less than 45º in order to obtain the highest possible positive portion of the securing force.

Cross lashing

The Cross lashing is a variant of head lashing and is easily applicable to stable load units, such as mesh pallets. Pallets are not required in this case because the belts are positioned by the load itself.

The roughly calculated securing force is obtained by adding the LC of the lashing eyes used. In the example on the right, four standard lashing eyes with 2,000daN each are used, giving a total of 8,000daN. The belts must have an LC of >2,000daN.

Here, the entire length should be used, especially for the belt ends coming from above (yellow arrow), in order to obtain the flattest possible angle.

The Bay lashing/head lashing can also be used for a load that cannot be placed against the end wall due to the load distribution. The application principle is the same.

Bay lashing/

The Bay lashing/ is a method that is also known as Loop Lashing and, like much else in the field of load securing, comes from the maritime industry. A sling is first placed around the load and the ends of the sling are then secured to the means of transport.

In the picture, the strap guide on a load can be seen clearly. As with head lashing, the LC of the belts and the lashing eyes is decisive.

The model shows the belt guide.

- Here the belt loop is hooked into the same eyelet with both ends. Provided that the hooks are seated correctly. The securing force is 2,000daN in each direction.

- Here, the strap ends are distributed over two eyelets. This results in a securing force of 2 x 2,000daN in each direction.

Securing in the direction of travel can be achieved by positive locking.

With the appropriate imagination, it is possible, as the pictures show, to find ways of securing machinery and equipment that come close to or exceed the effect of direct lashing.

Exceeding because the belt looped through in two lashing eyes hooked and thus the double LC can be used.

Your Sigurd Ehringer.

It's good that Sigurd has highlighted the differences. You can already see all kinds of adventurous constructions on the streets. You must never underestimate the physics.

On our own account:

Rothschenk. That's us.

Rothschenk is a manufacturer of load securing equipment for overseas containers. In the tranquil town of Aub in central Franconia, we develop, test and sell our own load securing equipment such as dunnage bags/padding, Lashing restraint systems, Edge Protectors, Anti-slip Mats, Lashing Straps and drum securement. You can get a small insight into our product world in our Online Shop: [R] SHOP24.

We develop for our customers, to whom also large corporations e.g. from the CHEMICALS-, BEVERAGES- and Automotive industry belong, individual load securing. Therefore we are used to come up with new products and solutions in our own research and test department.

We stand for quality "Made in Germany„. Not only in development, but also in production. Because we are the only manufacturer for load securing with our own production site in Germany. Real "Made in Germany" even.

>> Please use the comment function below for suggestions, additions and also for further questions.

We will, of course, respond promptly and professionally. Your Rothschenk Team

Schreibe einen Kommentar