Episode 29: Discard Maturity of Lashing Straps - The Criteria

Load securing on/trucks is usually carried out by positive or non-positive means.

What the form-fit method is all about and what needs to be taken into account, I have explained in the Episode 23 described.

In this episode, the securing device "tensioning belt" will be described in more detail, especially from the point of view of "discardability".

About the author:

In a series of specialist articles from the field, on topics relating to containers and trucks, you will receive first-hand professional knowledge.

How to secure cargo correctly and what are the basics of cargo securing?

They are developed and presented by Sigurd Ehringer, owner of SE-LogCon:

- VDI certified instructor for load securing

- Reference book author

- 8 years Project Manager

- 12 years with the Bundeswehr (company commander)

- 20 years of sales experience

- since 1996 consultant/trainer in logistics

- 44 years instructor/trainer in various fields

Episode 29: Discard Maturity of Lashing Straps - The Criteria

The regulation for manufacturing and testing of lashing straps is EN-12195-2 "Load securing on road vehicles" Safety Part 2 "Lashing straps made of man-made fibers" 2001-02.

The standard refers only to manually operated clamping elements with a maximum SHF of 500N=50daN. This is the normal force that must be applied to achieve the preload force (STF) specified by the manufacturer.

This standard is essentially a test specification, but it also describes the conditions of use and labeling.

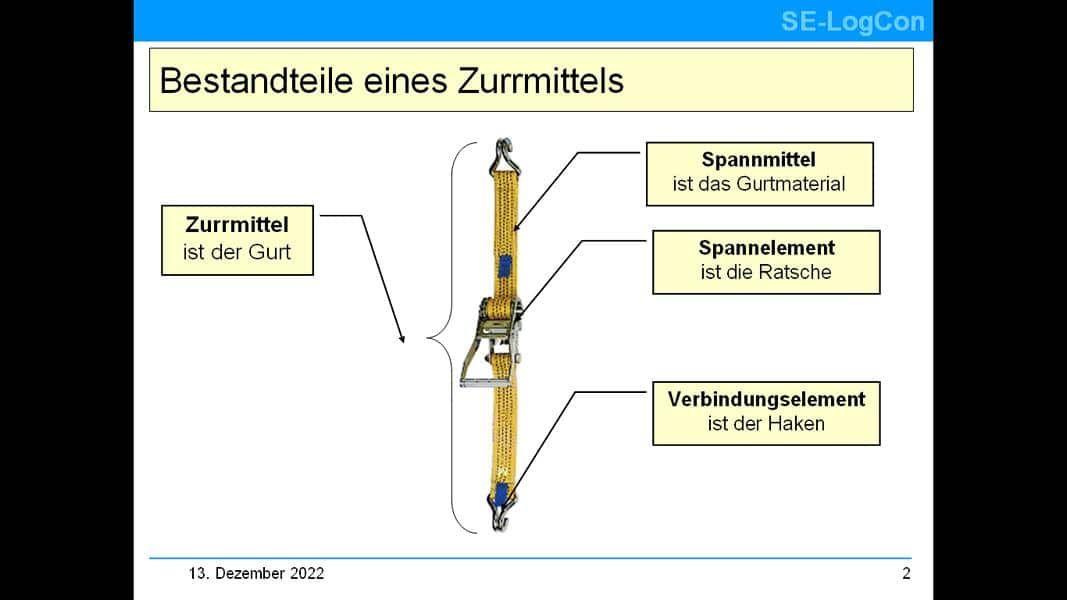

The components of the lashing means tension strap are in detail:

Another set of rules is VDI-2700 Sheet 3.1 "Instructions for use of lashing equipment" 03-2023.

The definition for damage is new. Here, the guideline specifies a measurable value.

Damage must not exceed 10% of the cross-section. This applies to both the width and the material thickness. In practice, damage related to the material thickness is often not sufficiently taken into account. With a material thickness of the webbing of approx. 3mm, damage of 10% = 0.3mm is quickly reached.

Both belts are ready for discard.

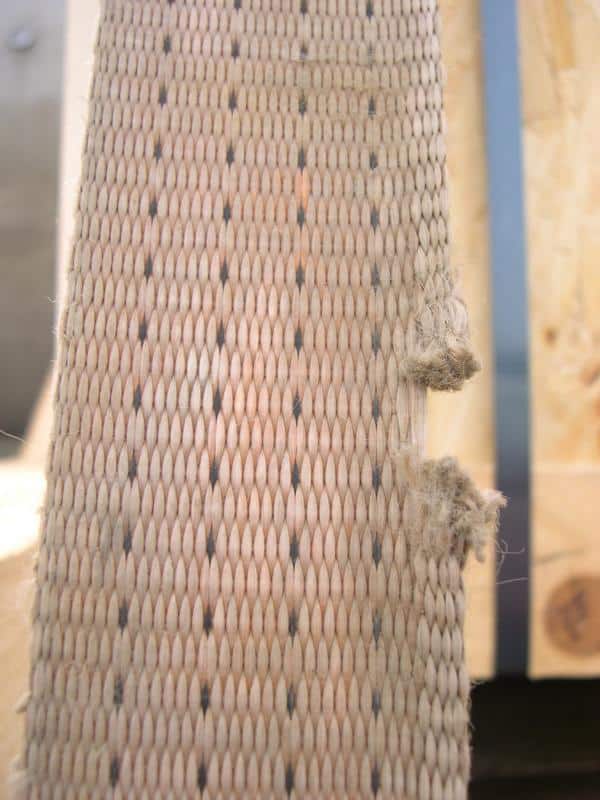

Excessive wear is also a discard criterion. It is not easy to assess this. The picture on the right shows a belt with damage such as occurs when the same load is always secured. Edge protectors or a hose edge protector would prevent such damage.

This belt is ready for discard.

Such damage occurs when the belt is hooked in and then the tuck-in slats rest directly on the belt. This inevitably damages it.

This belt is ready for discard.

Belts that are damaged at the seams or have been improperly repaired or manufactured as shown in the pictures are not permitted and must not be used.

This belt is ready for discard.

Excessive rust due to improper storage or keeping on the vehicle.

This belt is ready for discard.

This damage to the webbing indicates improper handling.

This belt is ready for discard.

Such damage to the ratchet occurs when the operator uses a batten, nail bar or metal pipe as an extension of the tensioning lever. The maximum hand force of 50daN was far exceeded.

Extensions are generally not permitted unless they are specifically built for this purpose.

This belt is ready for discard.

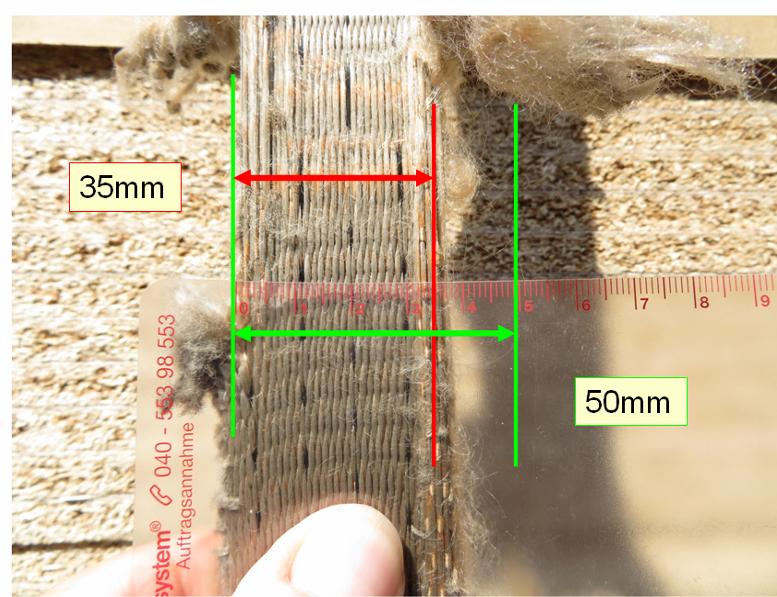

Damage to a belt due to overstretching, produced with an impermissible lever extension. From the original belt width 50mm, just 35mm are left.

This belt is ready for discard.

In order to facilitate the decision on discard maturity, especially when it comes to damage related to material thickness, the buckling test has proven its worth.

The strap is placed or bent over the finger in the damaged area.

It is easy to see whether the 10% limit has been exceeded or not.

Example: The damaged belt is hanging on the insertion bar.

The buckling test shows that the belt is definitely ablegreif, because the damage is more than 10% of the thickness of the material.

It is important that the belts on a vehicle are checked regularly. The driver as the user is responsible for this, but so is the vehicle owner. The driver is obliged to check that the belt is ready for discarding before each use.

The vehicle owner must provide written evidence of an inspection of the belts by an expert at least once a year.

However, the loader (managing director or appointed representative) must also ensure that no belts that are not suitable for discarding are used in the specific loading situation. If an incident occurs that would result in an administrative offense, and in any case if there are criminal consequences (e.g. negligent bodily injury), the loader would also be responsible. This can best be accomplished with a checklist for a receiving inspection, which includes the point of the belt check and is part of a work instruction.

Your Sigurd Ehringer.

Increase the discard strength of your lashing equipment with our Lashing strap rewinder.

Thanks to its stomach holder, it is quickly attached and you wrap your

Lashing straps up in record time. Save time and money now!

On our own account:

Rothschenk. That's us.

Rothschenk is a manufacturer of load securing equipment for overseas containers. In the tranquil town of Aub in central Franconia, we develop, test and sell our own load securing equipment such as dunnage bags/padding, Lashing restraint systems, Edge Protectors, Anti-slip Mats, Lashing Straps and drum securement. You can get a small insight into our product world in our Online Shop: [R] SHOP24.

We develop for our customers, to whom also large corporations e.g. from the CHEMICALS-, BEVERAGES- and Automotive industry belong, individual load securing. Therefore we are used to come up with new products and solutions in our own research and test department.

We stand for quality "Made in Germany„. Not only in development, but also in production. Because we are the only manufacturer for load securing with our own production site in Germany. Real "Made in Germany" even.

>> Please use the comment function below for suggestions, additions and also for further questions.

We will, of course, respond promptly and professionally. Your Rothschenk Team

Schreibe einen Kommentar