Episode 32: Load securing with Code XL bodies

The Code XL body, the magic word in load securing.

Quite a few shippers and also drivers are of the opinion that now it is only necessary to load and no longer to secure.

That is only partially correct. The wise answer is: "it depends". Yes on what?

About the author:

In a series of specialist articles from the field, on topics relating to containers and trucks, you will receive first-hand professional knowledge.

How to secure cargo correctly and what are the basics of cargo securing?

They are developed and presented by Sigurd Ehringer, owner of SE-LogCon:

- VDI certified instructor for load securing

- Reference book author

- 8 years Project Manager

- 12 years with the Bundeswehr (company commander)

- 20 years of sales experience

- since 1996 consultant/trainer in logistics

- 44 years instructor/trainer in various fields

Episode 32: Load securing with Code XL bodies

The European standard with the unwieldy title:

EN-12642 "Load securing on road vehicles - Bodies on commercial vehicles - Minimum requirements" is actually a test specification for bodies.

Regardless of how the structure is technically designed, must:

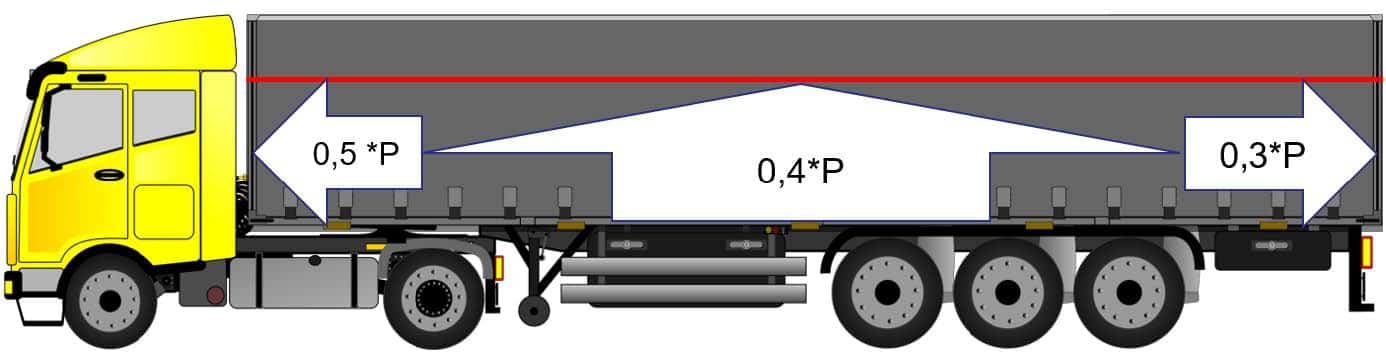

- the full width and up to ¾ of the height of the end wall can withstand a force corresponding to 50% of the technical payload

- the lateral structure must hold 40%

- and the rear portal 30%

These forces must be tested and verified either statically or dynamically within the framework of driving tests. The structure may deform elastically by up to 300mm. A permanent deformation of a maximum of 20mm is permissible, provided that the function is not impaired.

In the latest edition, it is explicitly stated that the proven forces may also be used for calculating the load securing. This was not the case in previous editions, although most shippers have kept it that way.

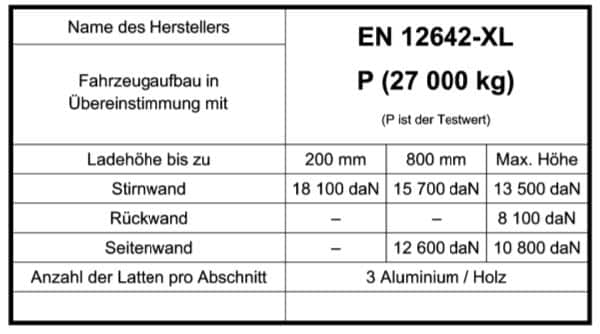

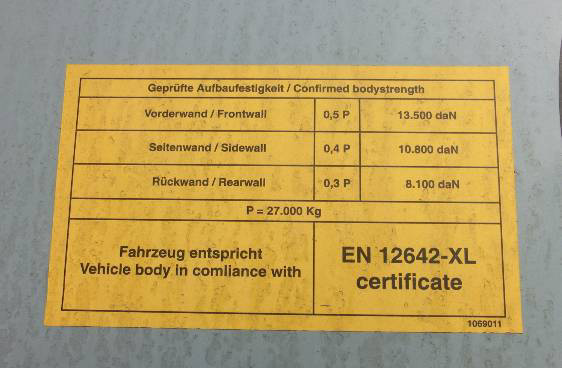

Proof of this test is usually provided in the form of a certificate in which the manufacturer also specifies the boundary conditions under which the body can be used for load securing. It is also stipulated that the body must be checked annually by experts for suitability. The certificate also states the technical payload and the chassis number to which it refers.

Die meisten Hersteller beschreiben in ihren Zertifikaten die folgenden Randbedingungen für die Ladungssicherung über den Aufbau:

- Positive loading/stowing starting at the end wall

- Load width 2,40m

- Maximum distance to the rear portal 15cm

- Coefficient of friction of the loading surface of at least μ=0.3

The standard requires manufacturers to mark their vehicles with a label that provides the shipper/driver with key information about body strength.

The figures are manufacturer-specific and body-related.

Unfortunately, this is not implemented in a compliant manner by some manufacturers, but is designed differently and is not affixed in the recommended place. Irrespective of the manufacturer's labeling obligation, the shipper should ensure organizationally that the driver has the certificate to hand.

The certificate usually also contains a Solomonic note from the manufacturer to the effect that, in the event of deviating conditions, additional securing measures must be taken in accordance with VDI-2700ff "Load securing on road vehicles".

In practice, however, there is not infrequent confusion about how the boundary conditions must be implemented. The causes are usually that the load does not fit as optimally on the vehicle as one or the other would like. Causes can be:

- The loading units do not correspond to the Euro dimension and are too long, too short, too wide or too narrow

- The load units are too heavy and the payload is exhausted, but the truck is not fully loaded

- The load distribution causes problems

- The loading units are unstable (e.g. Bigbags or octabins)

Misapplications

Due to the load distribution, the load must be placed to the rear. A Euro pallet standing on edge was installed as a spacer. It acts like a can opener

This is the result of an unsuitable spacer. The end wall was pushed out to the front during braking.

This is what the body looks like when the load has moved. It lies in the tarpaulin on the right and bends the upper roof girders. This can be seen particularly clearly on the left roof girder.

If loaded incorrectly, even the end wall cannot hold the load.

(Source: KLSK; Photo-of-the-month 2016-03)

As soon as the load width falls below 2.40m, the load must be secured.

It is questionable whether simple tie-down lashing is sufficient in this case. No Anti-slip Mats used and the belt runs over the unstable loading flap of the mesh box.

If there are significant incidents (e.g. due to damage to the body) with the load securing, the shipper is required to prove how he evaluated the body and what conclusions he drew from this.

Under no circumstances should you rely on statements from drivers such as "it'll hold". In critical cases, the safest decision is to refuse the load.

The next issue of the LaSi blog will describe cargo types where problems are likely to occur and what measures can be taken.

Your Sigurd Ehringer.

Load securing consists of a large number of components.

The truck body like the Code XL described here is one of them.

With our professional LaSi resources, we make another important contribution to safety.

On our own account:

Rothschenk. That's us.

Rothschenk is a manufacturer of load securing equipment for overseas containers. In the tranquil town of Aub in central Franconia, we develop, test and sell our own load securing equipment such as dunnage bags/padding, Lashing restraint systems, Edge Protectors, Anti-slip Mats, Lashing Straps and drum securement. You can get a small insight into our product world in our Online Shop: [R] SHOP24.

We develop for our customers, to whom also large corporations e.g. from the CHEMICALS-, BEVERAGES- and Automotive industry belong, individual load securing. Therefore we are used to come up with new products and solutions in our own research and test department.

We stand for quality "Made in Germany„. Not only in development, but also in production. Because we are the only manufacturer for load securing with our own production site in Germany. Real "Made in Germany" even.

>> Please use the comment function below for suggestions, additions and also for further questions.

We will, of course, respond promptly and professionally. Your Rothschenk Team

Schreibe einen Kommentar