Refrigerated containers have become an integral part of the logistics industry. They offer the option of transporting chilled goods at a defined temperature and monitoring the temperature profile.

Compared to the past, when cooling still had to take place via the means of transport, today’s integral containers are easier to handle. The refrigeration unit is built into the container, which has the minor disadvantage that less storage space is available because the external dimensions are standardized.

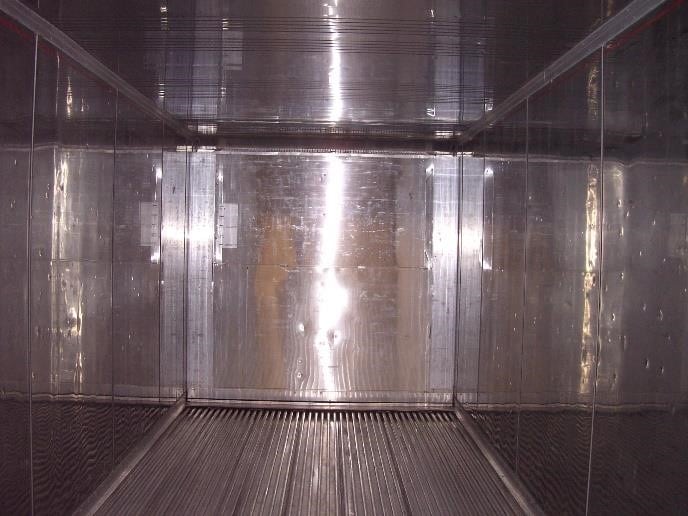

The two pictures show a typical type 45R1 refrigerated container with an integrated refrigeration unit at the front.

The view into the interior shows the aluminum cladding and the floor consisting of aluminum grating. This type of floor is mainly used for airflow.

The markings slightly below the ceiling show the maximum height at which the load may be stowed so as not to impede air circulation. The marking can also be designed as a line. The type of execution is not defined.

Securing the load is somewhat difficult because the refrigerated container does not have the usual lashing points on the lower and upper side members. It is designed for form-fitting and complete filling of the load compartment.

Another special feature is the floor. It consists of longitudinal gratings to ensure air circulation in the container.

The heated air is drawn in from the top of the unit, cooled in the unit and pressed back into the bottom of the grill.

The power of the unit is not designed to cool a load to the target temperature, but to keep the load at the temperature it has at the time of stowage. Palletized goods in particular should be stowed in such a way that the air can also flow upwards between the load sections.

The gaps in this load allow sufficient upward air flow. The upright pallets as spacers and gap fillers facilitate this.

It is essential to observe the maximum stowage height to ensure temperature control during the entire transportation process.

If form-fit stowage in the container is not possible, other aids must be used. Lashings are standard applications that rely on the presence of lashing points.

It is precisely these lashing points that are uncertain. They are not included in all refrigerated containers. It is crucial to point out that lashing points are required when purchasing the container. The shipping company or freight forwarder should be able to provide information about their loading capacity.

The arrows point to bars in the base of the grating that are intended for attaching lashing. They are not standardized.

The position on the floor is not standardized, but differs from manufacturer to manufacturer. The tensile strength (LC) is also not defined. In case of doubt, it is essential to consult the manufacturer, shipping company or forwarding agent.

When using dunnage bags, care must be taken to ensure that the internal pressure also reacts to temperature fluctuations.

If the temperature is relatively high at the time of stowage and is then lowered considerably by the cooling unit, this can lead to problems due to a drop in pressure. This must be taken into account when planning transportation.

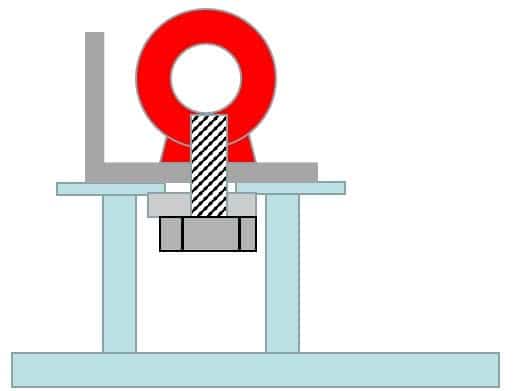

Various lashing points are available on the market. It is important to observe the manufacturer’s instructions for use or to ask for them.

This lashing point is designed for attaching lashing straps for the tie-down lashing method.

To a lesser extent, the vertical edge can also be used for positive locking.

The diagram shows how the lashing point is pushed from the door side into the grating floor.

The eyebolt must be screwed into the bearing with a specified torque in order to increase the friction via the contact pressure.

Always observe the manufacturer’s instructions.

Another system for securing loads is based on air-filled dunnage bags. The so-called “SAM system”.

It consists of two interconnected stowage pads, which are additionally coated with anti-slip material on the outside, creating an additional frictional force to the container walls in addition to the form fit.

The side stowage cushions are connected to a sturdy tarpaulin, especially in the door-side system, which additionally secures the load. A tarpaulin can also be useful on the top of small loads.

The dimensions must be prepared in such a way that the cross tarpaulin is taut after filling.

The S.A.M. system is customized for the specific application.

The shipping company must therefore consider how its products can be secured in the refrigerated container so that the requirements of the CTU Code are met.

The shipping company and the control authorities in the port are guided by these specifications. In case of doubt, the container does not go on board. This delay can result in unpleasantly high costs.

It is certainly cheaper to agree on a sensible, practical and safe solution with the experts beforehand.

Yours, Sigurd Ehringer

<< To the previous post

Episode 30: Damage to the truck – When should you refuse a load?

To the next post >>

Episode 32: Load securing with Code XL superstructures

Tobias Kreft

Rothschenk assortment

Our customer center has only one goal: to turn your problems into solutions. Whether standard stowage cushions, bestsellers or load securing personally tailored to your needs -. we accompany you consistently from A as in field service to Z as in certification. That is our promise to you, as a leader in our industry.

We attach great importance to professional cargo securing. That is why we have our own production, which ensures reliable operation through modern manufacturing technologies and strict quality control. Thus, we offer our customers a comprehensive and high-quality range of services in the field of transport logistics.

DIN ISO 9001:2015, EMAS and Ecovadis are not foreign words to you? Then it's time to work with the best.

You don't take any risks with us - we have been awarded the Platinum Medal on the EcoVadis sustainability rating platform.

As a load securement company, we are proud to have several certifications that validate our sustainability efforts and our commitment to environmental protection and social responsibility. For you as a purchaser, this means that we demand and promote the implementation of high environmental and social standards both within the company and along the supply chain.

G&H GmbH Rothschenk

Industriestrasse 5 & 7-10

97239 Aub

Phone: +49 9335 97 15 – 79

Fax: +49 9335 97 15 – 15

E-mail: info@rothschenk.de

Collection/delivery

Mon – Fri: 8:00 – 15:00

Office hours

Mon – Thu: 8:00 – 17:00

Fri: 8:00 am – 1:00 pm

G&H GmbH Rothschenk

Industriestrasse 5 & 7-10

97239 Aub

Phone: +49 9335 97 15 – 79

Fax: +49 9335 97 15 – 15

E-mail: info@rothschenk.de

Collection/delivery

Mon – Fri: 8:00 – 15:00

Office hours

Mon – Thu: 8:00 – 17:00

Fri: 8:00 am – 1:00 pm